Hot mixing machine for plastic processing

A heat mixer and plastic technology, applied in the field of plastic processing equipment, can solve the problems of uneven heating of resin and uniform mixing of resin, and achieve the effect of good heating effect and avoiding excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

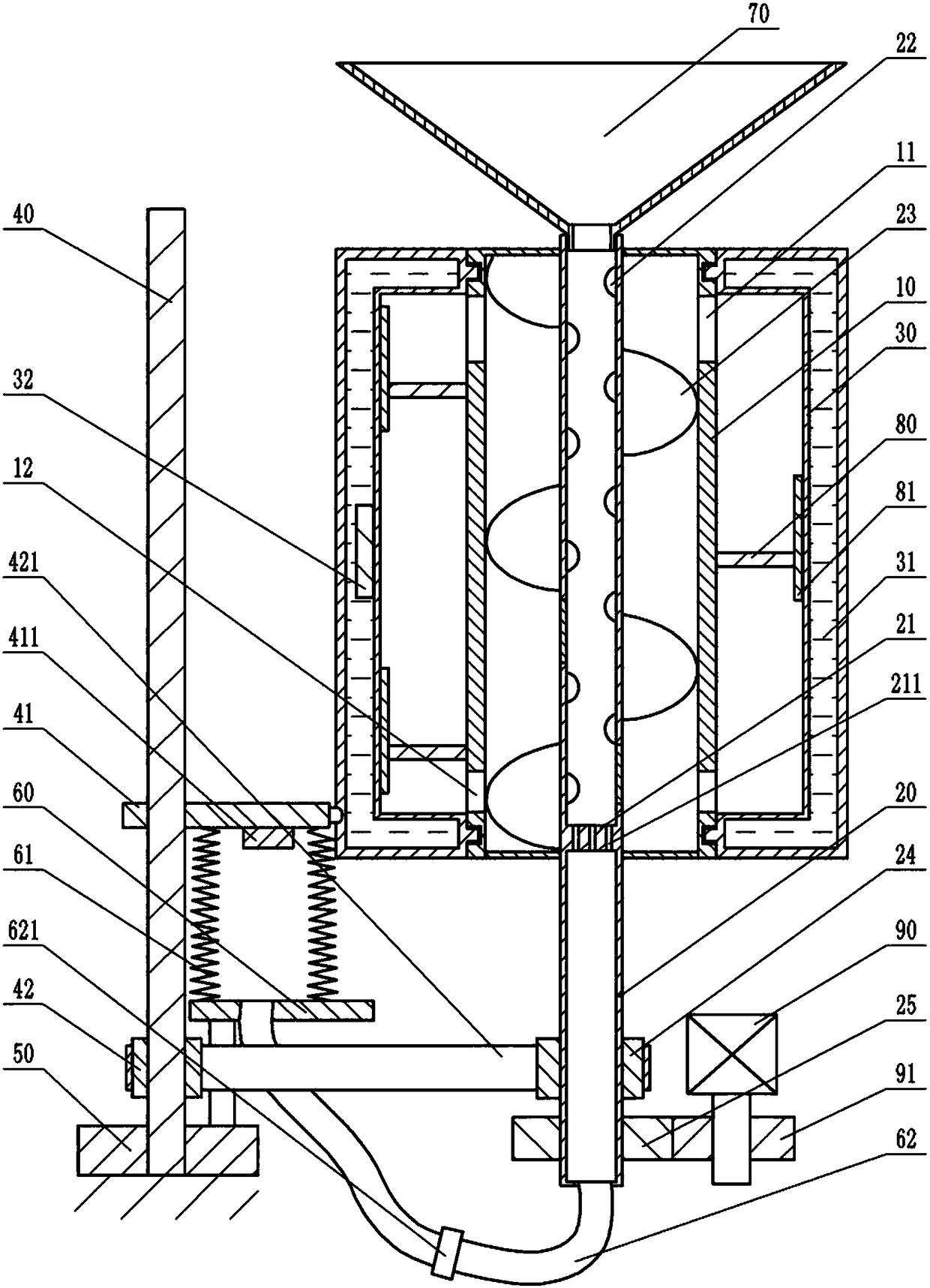

[0020] Instructions attached figure 1 The reference signs in include: fixed cylinder 10, feed port 11, discharge port 12, hollow shaft 20, partition 21, air hole 211, friction protrusion 22, spiral blade 23, second friction wheel 24, first Gear 25, rotating cylinder 30, heating chamber 31, first electric heating wire 32, threaded rod 40, pressing plate 41, second electric heating wire 411, first friction wheel 42, conveyor belt 421, frame 50, support plate 60, corrugated Pipe 61, air pipe 62, one-way exhaust valve 621, hopper 70, stirring shaft 80, scraper 81, motor 90, second gear 91.

[0021] Such as figure 1 As shown, the thermal mixer for plastic processing includes a thermal mixing unit, a power unit, a transmission unit and a preheating unit. The thermal mixing unit includes a fixed cylinder 10, a rotating cylinder 30 and a hollow shaft 20, the fixed cylinder 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com