A kind of integral rod filling and air forming method

A molding method and an integrated technology, which can be applied to household appliances, other household appliances, household components, etc., and can solve the problems of easy rupture of membrane tubes, air leakage, and high defective ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

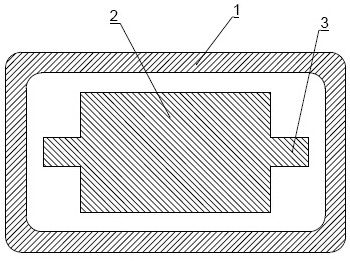

Image

Examples

Embodiment 1

[0027] A method for forming an integrated rod by filling air described in this embodiment specifically includes the following steps:

[0028] (1) Prepare a thickened silicone tube, one end of the thickened silicone tube is closed, and the wall thickness of the thickened silicone tube is 2mm;

[0029] (2) Select a profiling tool with the same shape as the thickened silicone tube, put a nylon membrane tube on the outer jacket of the profiling tool, close one end of the nylon membrane tube, and extract the air between the nylon membrane tube and the profiling tool to make the Nylon film tube is attached to the imitation tool;

[0030] (3) Wrap several layers of sheet-like carbon fiber yarns or glass fiber yarns with sticky resin on the profiling tool wrapped with nylon film tubes;

[0031] (4) Pull out the profiling tool to obtain a straight rod preform;

[0032] (5) Insert the thickened silicone tube into the nylon membrane tube inside the straight rod preform, and connect the...

Embodiment 2

[0044] A method for forming an integrated rod by filling air described in this embodiment specifically includes the following steps:

[0045] (1) Prepare a thickened silicone tube, one end of the thickened silicone tube is closed, and the wall thickness of the thickened silicone tube is 4 mm;

[0046] (2) Select a profiling tool with the same shape as the thickened silicone tube, put a nylon membrane tube on the outer jacket of the profiling tool, close one end of the nylon membrane tube, and extract the air between the nylon membrane tube and the profiling tool to make the Nylon film tube is attached to the imitation tool;

[0047](3) Wrap several layers of sheet-like carbon fiber yarns or glass fiber yarns with sticky resin on the profiling tool wrapped with nylon film tubes;

[0048] (4) Pull out the profiling tool to obtain a straight rod preform;

[0049] (5) Insert the thickened silicone tube into the nylon membrane tube inside the straight rod preform, and connect the...

Embodiment 3

[0061] A method for forming an integrated rod by filling air described in this embodiment specifically includes the following steps:

[0062] (1) Prepare a thickened silicone tube, one end of the thickened silicone tube is closed, and the wall thickness of the thickened silicone tube is 3mm;

[0063] (2) Select a profiling tool with the same shape as the thickened silicone tube, put a nylon membrane tube on the outer jacket of the profiling tool, close one end of the nylon membrane tube, and extract the air between the nylon membrane tube and the profiling tool to make the Nylon film tube is attached to the imitation tool;

[0064] (3) Wrap several layers of sheet-like carbon fiber yarns or glass fiber yarns with sticky resin on the profiling tool wrapped with nylon film tubes;

[0065] (4) Pull out the profiling tool to obtain a straight rod preform;

[0066] (5) Insert the thickened silicone tube into the nylon membrane tube inside the straight rod preform, and connect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com