Early-strength sulphoaluminate cement paste capable of being easily pumped, and preparation method thereof

A technology of sulphoaluminate cement and strong sulphoaluminate, which is applied in the field of cement performance adjustment, can solve the problems that it is difficult to meet the construction process requirements of construction projects, the setting time is not easy to control, and the loss of fluidity is fast, so as to shorten the initial setting and final setting time, promote the secondary hydration reaction, and promote the effect of setting and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

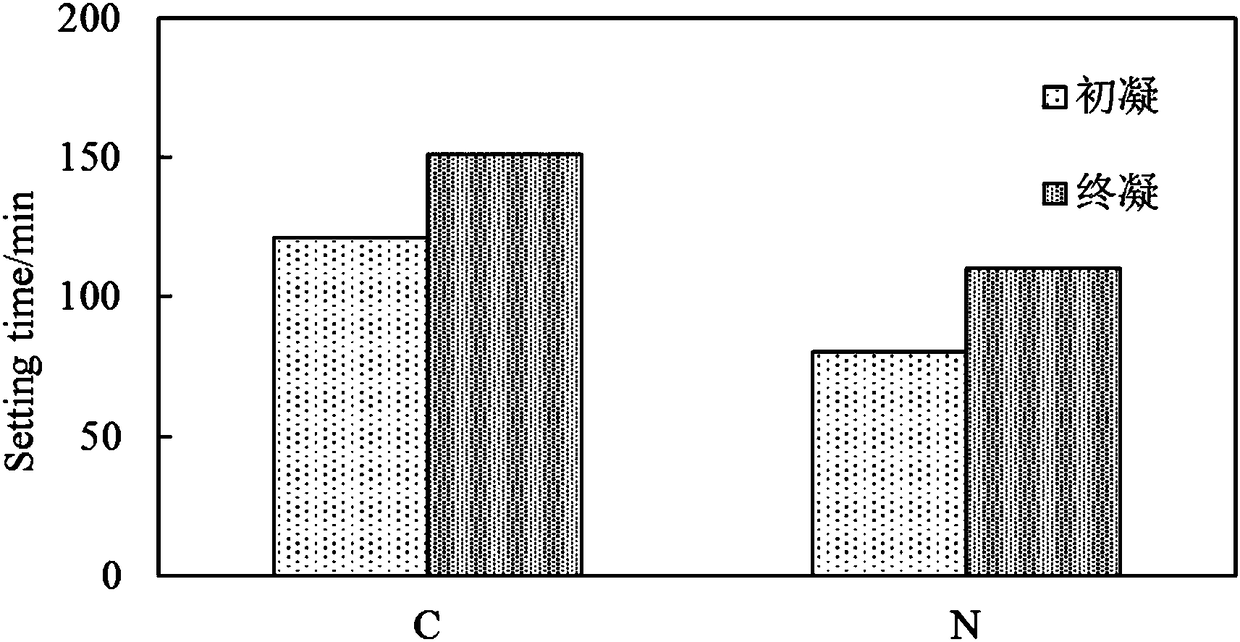

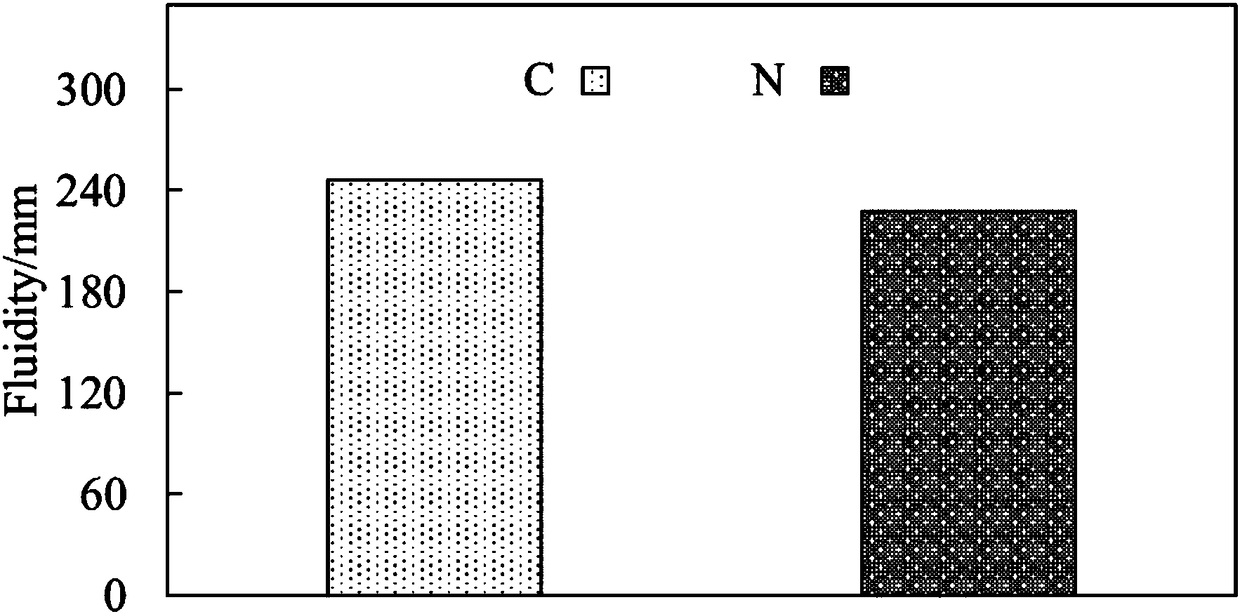

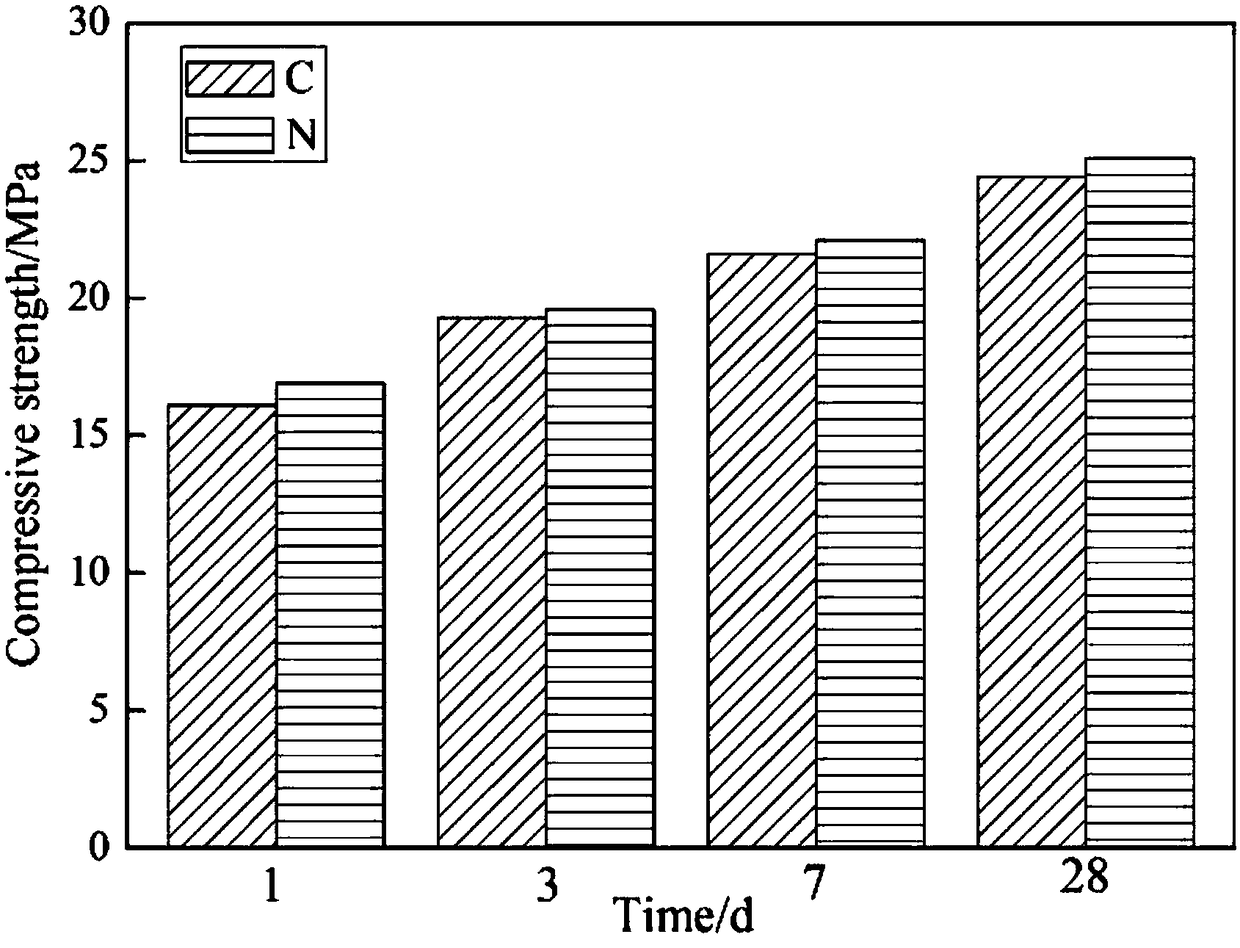

[0027] Sulphoaluminate cement accounts for 80% of the total mass of the cementitious material, and fly ash accounts for 20% of the total mass of the cementitious material, and 0.0125wt.% lithium carbonate (chemically pure reagent) is added outside; first lithium carbonate is mixed with water Evenly, then pour the cementitious material, put it on the cement slurry mixer and stir slowly for four minutes, test the initial setting and final setting time of the cement slurry, fluidity, and test the compressive strength of the cement slurry within 28 days strength.

[0028] like Figures 1 to 3 As shown, when the amount of lithium carbonate was 0.0125wt.%, the initial setting and final setting time of the cement slurry were significantly shortened, and the fluidity of the cement slurry was slightly reduced (the influence of the fluidity was very small). The compressive strength continued to increase.

Embodiment 2

[0030] Sulphoaluminate cement accounts for 80% of the total mass of the cementitious material, and fly ash accounts for 20% of the total mass of the cementitious material, and 0.025wt.% lithium carbonate (chemically pure reagent) is added outside; first lithium carbonate is mixed with water Evenly, then pour the cementitious material, put it on the cement slurry mixer and stir slowly for four minutes, test the initial setting and final setting time of the cement slurry, fluidity, and test the compressive strength of the cement slurry within 28 days strength.

[0031] Test situation: if Figures 4 to 6 As shown, when the amount of lithium carbonate was 0.025wt.%, the initial setting and final setting time of the cement slurry were significantly shortened, and the fluidity of the cement slurry was slightly reduced (the influence of the fluidity was very small), and at the same time within 28 days of age The compressive strength continued to increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com