A chemical constant temperature anaerobic degradation device capable of continuous sampling

A chemical and constant temperature technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical equipment and methods, etc., can solve the problem of affecting the reaction conditions of reaction devices, reducing the accuracy and reliability of reaction experiment data There are problems such as controllable temperature to achieve the effect of improving integration efficiency, good thermal insulation performance and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

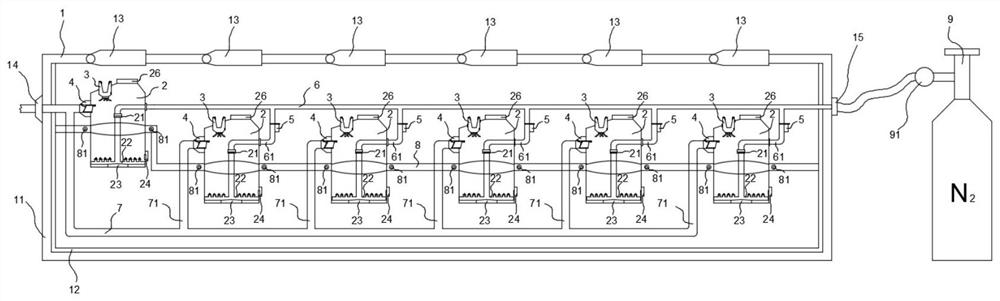

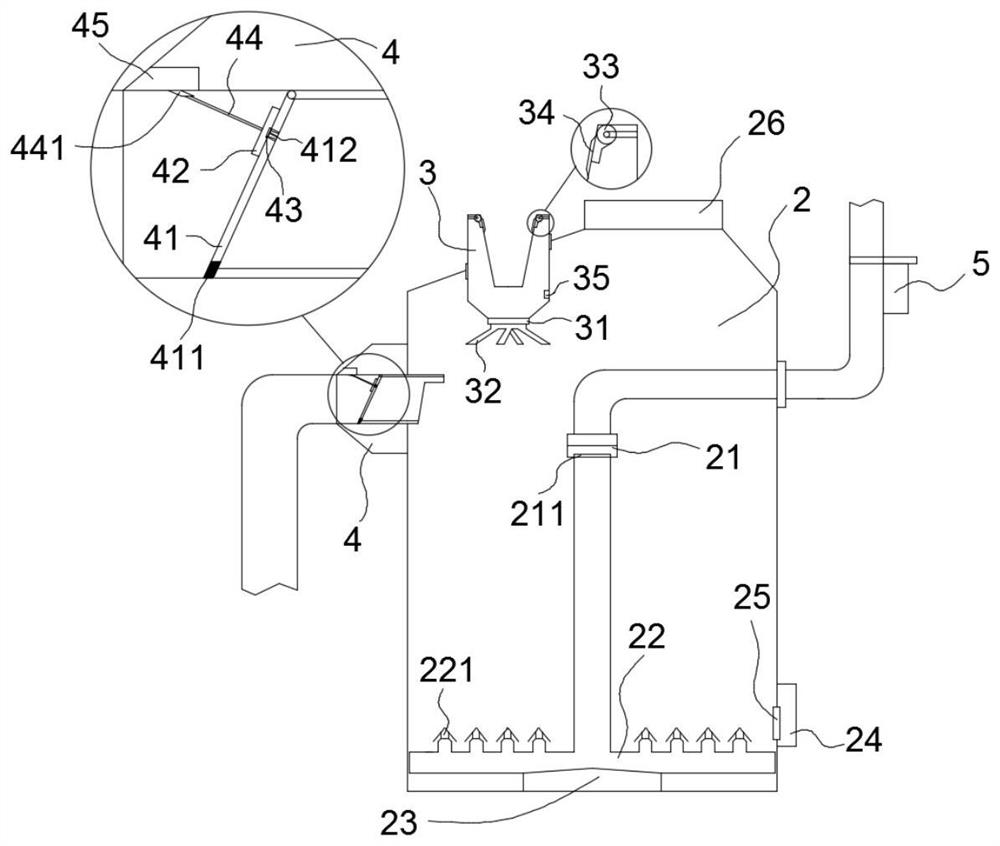

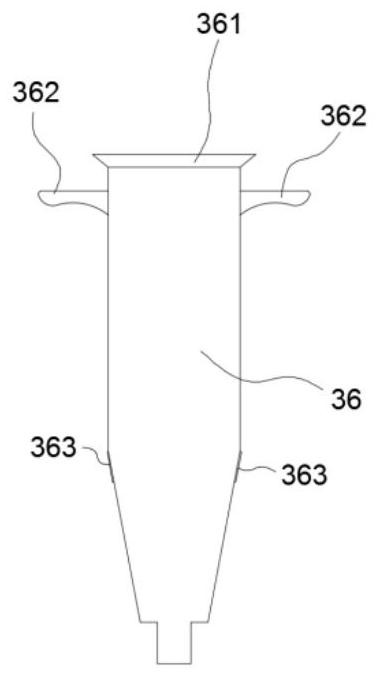

[0031] Such as figure 1 with 4 As shown, a chemical constant temperature anaerobic degradation device capable of continuous sampling mainly includes a temperature control box 1, a reaction device 2, a gas delivery pipe 6, an exhaust pipe 7, a fixing frame 8 and a nitrogen bottle 9; the inner wall of the temperature control box 1 The 6 sides of the are provided with thermal insulation layer 11, such as Image 6 As shown, the left side of the insulation layer 11 is the outer plate 111, and there are inclined plates arranged between the outer plate 111 and the inner wall of the temperature control box 1. The inclined plates are distributed longitudinally at equal intervals, and the inclination angle is 30°. There are also two vertical plates interspersed between them. The vertical plates are distributed perpendicular to the slanting board, forming a triangular compartment a112 and a rectangular compartment b113. The compartment a112 is filled with fireproof materials, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com