Vertical type silicon wafer magnetron sputtering film plating machine

A technology of magnetron sputtering and coating machine, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc. It can solve the problems of uneven coating, large size of silicon wafer placement board, and high failure rate of equipment. Achieve the effect of improving coating quality, good vacuum effect and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

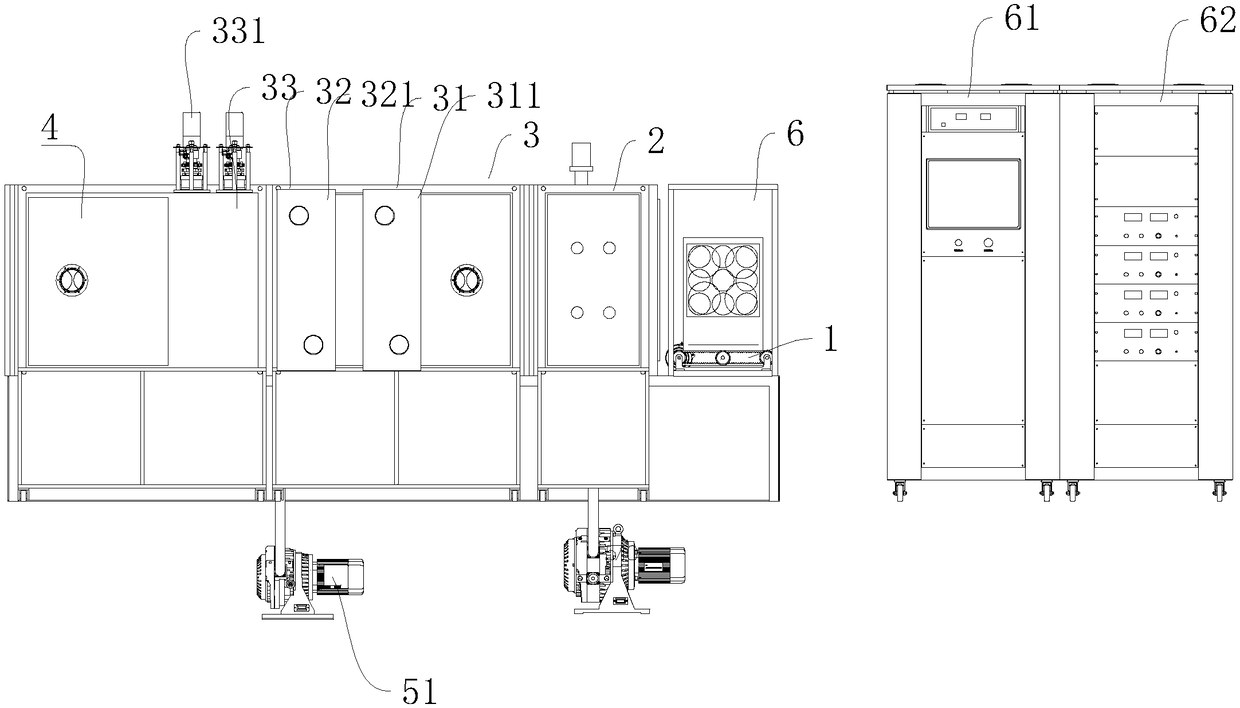

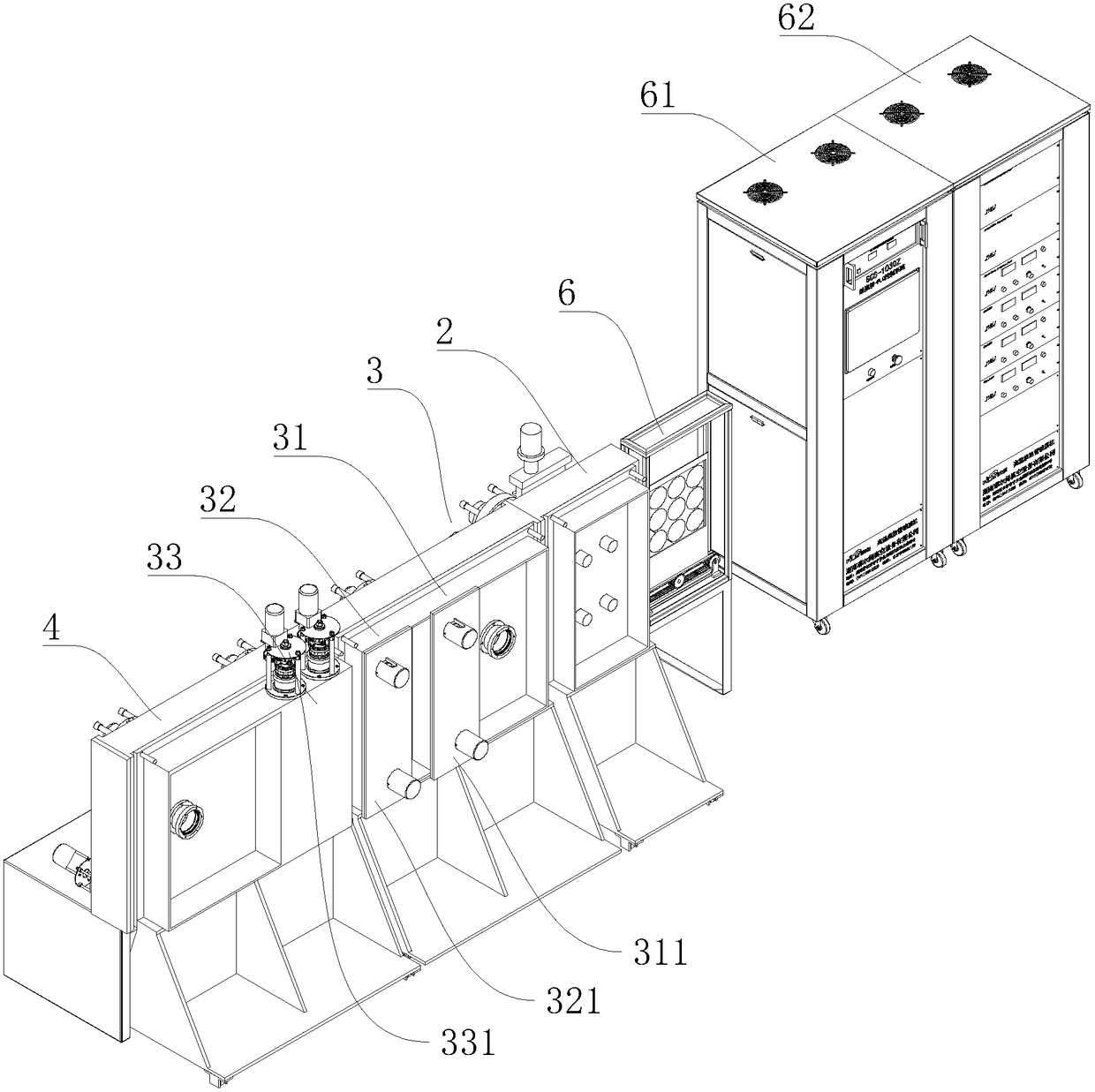

[0030] Such as Figure 1-Figure 6 Shown is a kind of vertical magnetron sputtering coating machine for silicon wafers of the present invention, comprising: a vacuum chamber, a transmission device 1 arranged in the vacuum chamber for suspending and moving silicon wafers, and a vacuum pumping system and a power control system;

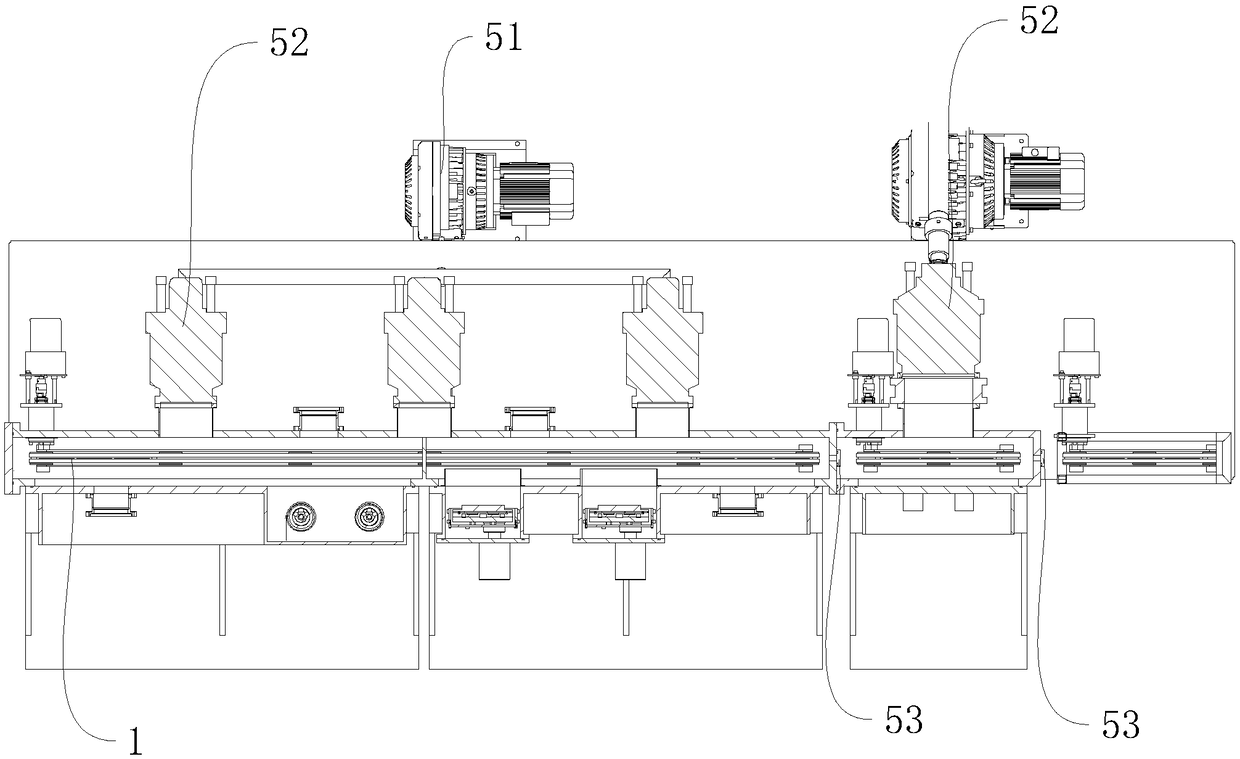

[0031] Such as Figure 5-Figure 6 As shown, the transmission device 1 includes a silicon wafer hanging plate 13, a hanging plate base 14, and a rail car 15 arranged in a vacuum chamber. The silicon wafer hanging plate 13 and the hanging plate base 14 are detachably connected; The bottom of the hanging board base 14 is provided with a protrusion, and the hanging board base 14 is fixedly plugged with the rail car 15 through the cooperation of the protrusion and the groove.

[0032] Wherein, the groove includes a first groove 151 arranged in the middle position of the top of the rail car 15 and a plurality of second grooves 152 arranged on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com