A horizontal feeding hemp stem separator

A feeding type, separator technology, applied in the direction of fiber mechanical separation, mechanical treatment, textile and papermaking, etc., can solve the problems of poor separation effect and complex structure, and achieve high production efficiency, high degree of automation, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

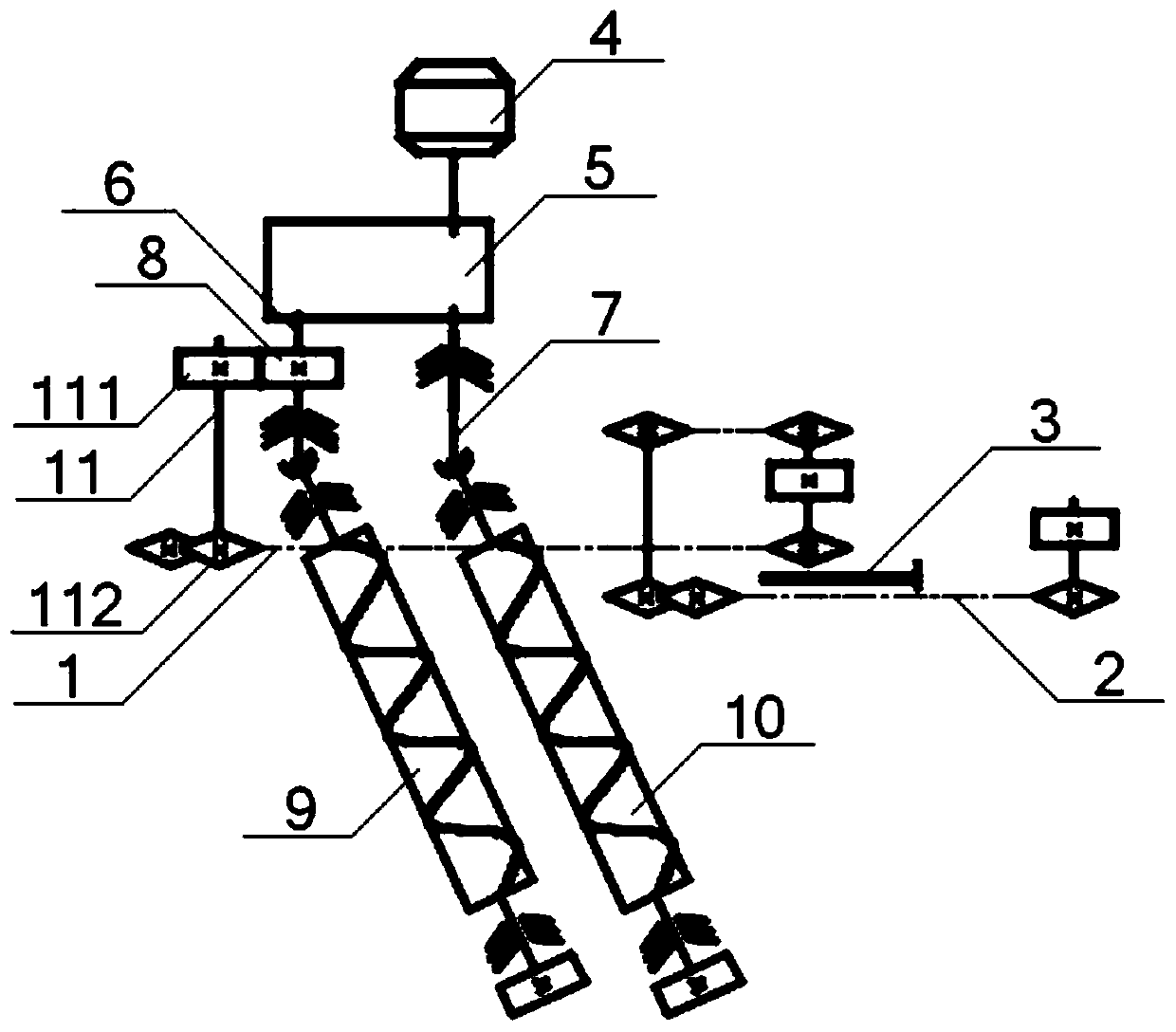

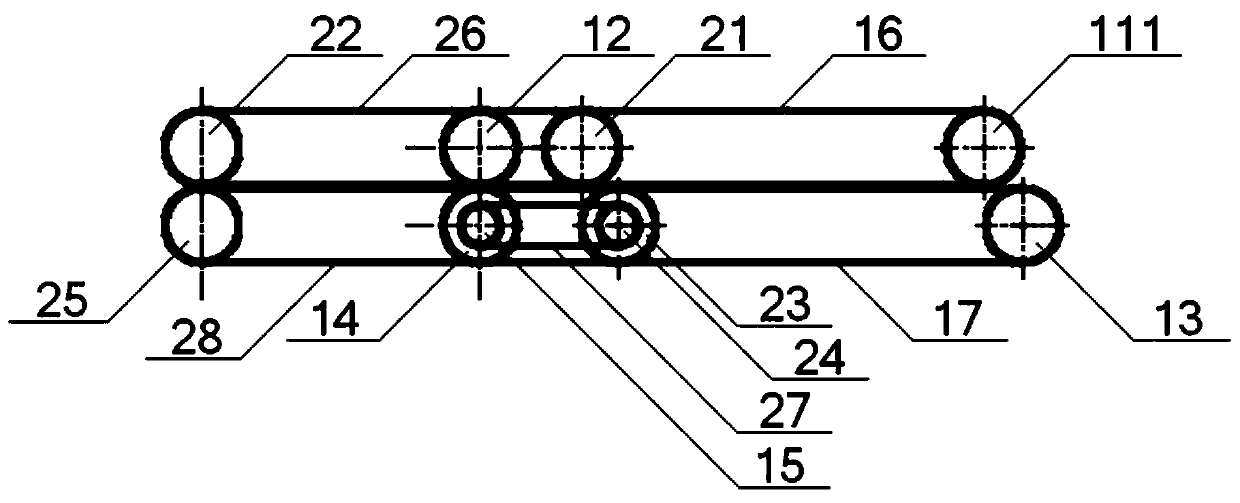

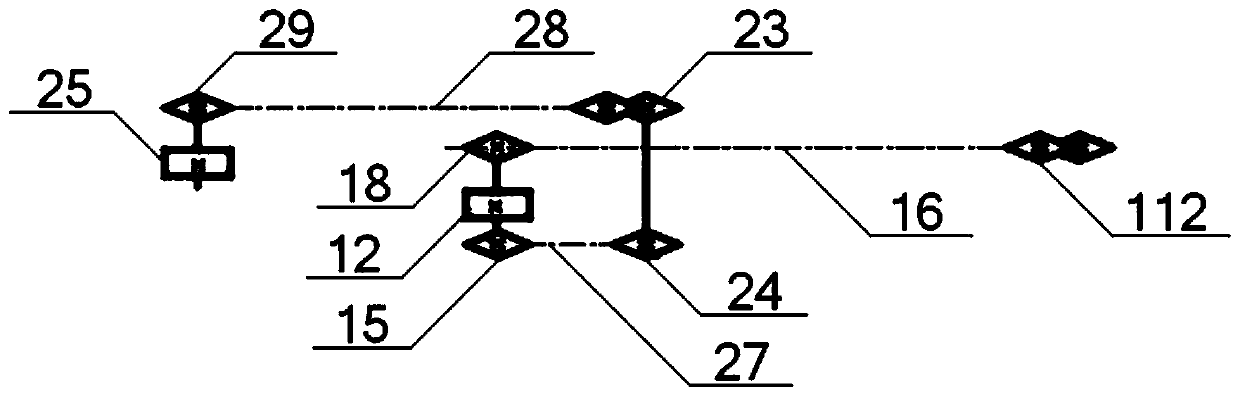

[0041] see figure 1 , a horizontal feeding hemp stalk separator, comprising a frame and a feeding clamping mechanism arranged horizontally on it, the feeding clamping mechanism includes a first clamping unit 1 and a second clamping unit 2 , the first clamping unit 1 and the second clamping unit 2 are parallel to each other, the rear end of the first clamping unit 1 is connected to the front end of the second clamping unit 2, and the first clamping unit is located on the frame The position between the rear end of the unit 1 and the front end of the second clamping unit 2 is equipped with a hemp scraping unit 3, and a power unit is installed on the position on the side of the first clamping unit 1 on the frame, and the first clamping unit is located on the frame. The position on the other side of the clamping unit 1 is sequentially equipped with a breaking unit 9 and a hemp-stripping unit 10 from front to back, and the power unit is connected with the breaking unit 9 and the hem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com