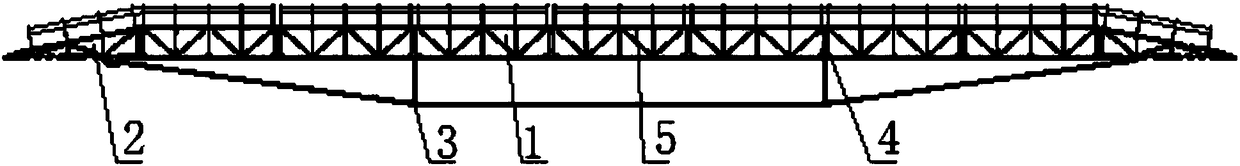

Composite-metal combined large-span bridge with lower chord reinforcing system

A composite material and reinforcement system technology, applied in bridges, truss bridges, bridge parts, etc., can solve problems such as poor maneuverability of bridges, large operating tasks, and self-heavyness, and achieve enhanced bending and torsional rigidity, and enhanced cross-section overall performance, and the effect of improving load-carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

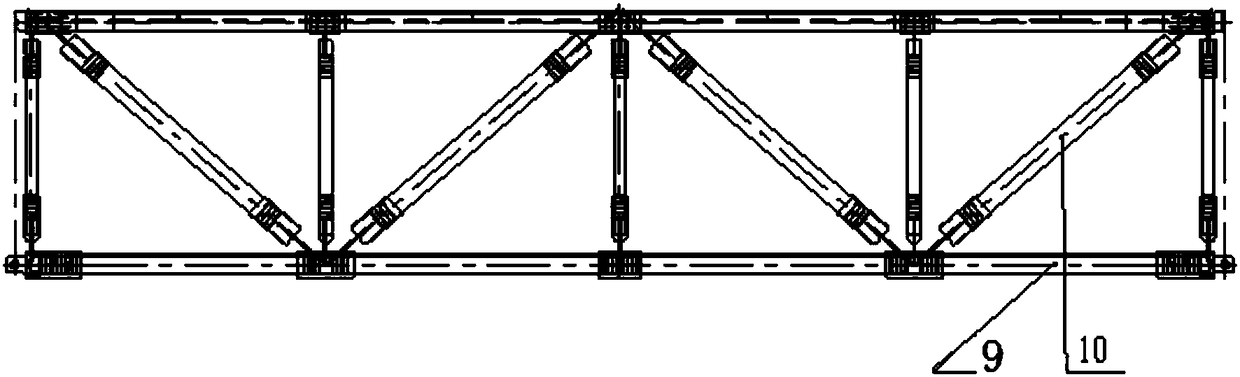

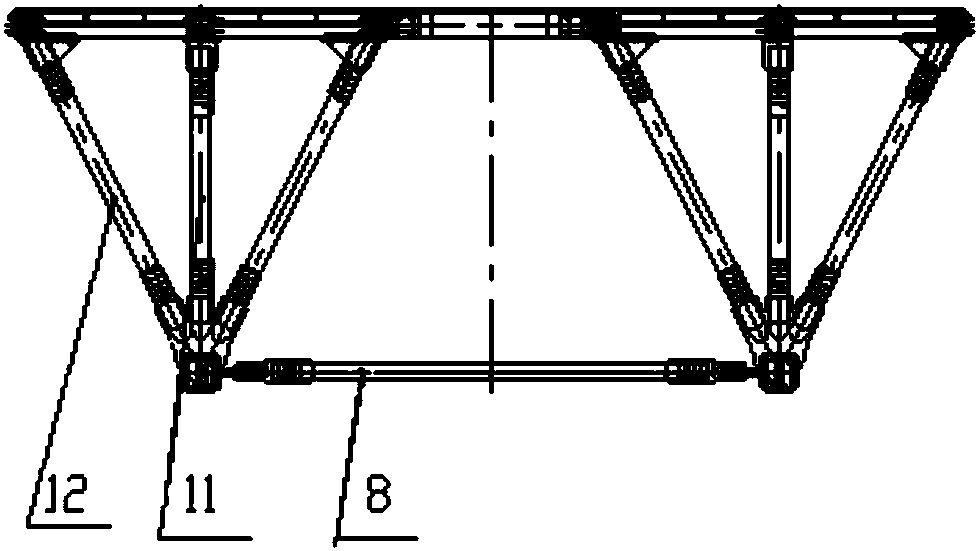

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Factors such as self-weight, span, and structural form of emergency bridges often influence and restrict each other. Therefore, in the design of emergency bridges, materials and structural forms need to be considered as a whole that affects each other. In view of the relatively clear force transmission mechanism of the space truss and the relatively single force transmission path of the bar, it is a structural form with high load-bearing efficiency. The fiber-reinforced resin-based pultruded composite material has high fiber content, high material utilization rate, and excellent unidirectional mechanical properties. If the fiber-reinforced resin-based pultrusion profile and the truss structure are jointly designed, the advantages of the two can be fully utilized, thereby achieving the goal of substantial weight reduction. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com