Piston combustor structure

A combustion chamber and piston technology, applied in the field of piston combustion chamber structure, can solve problems such as increased fuel consumption, difficult combustion control, insufficient combustion, etc., and achieve the effect of reducing fuel consumption and combustion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings.

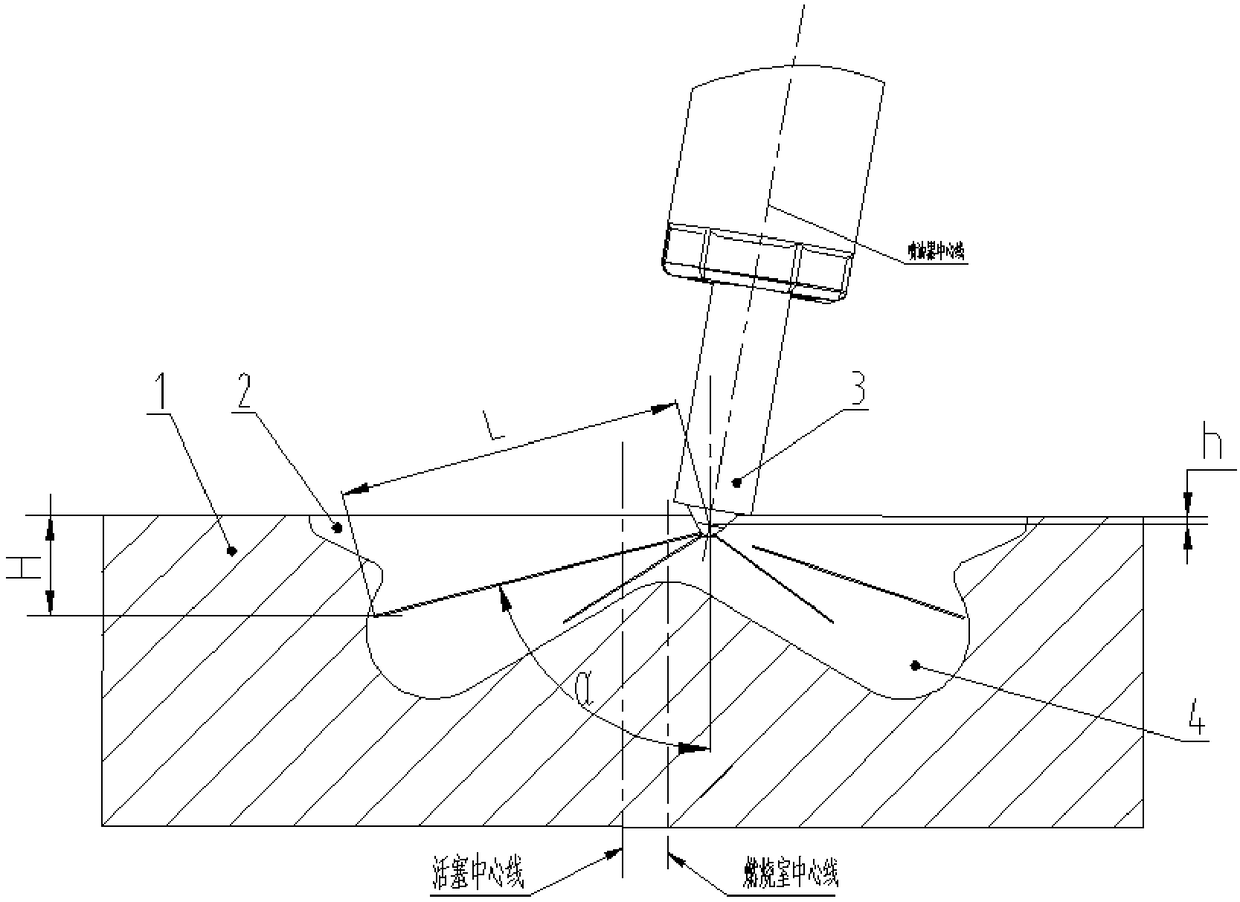

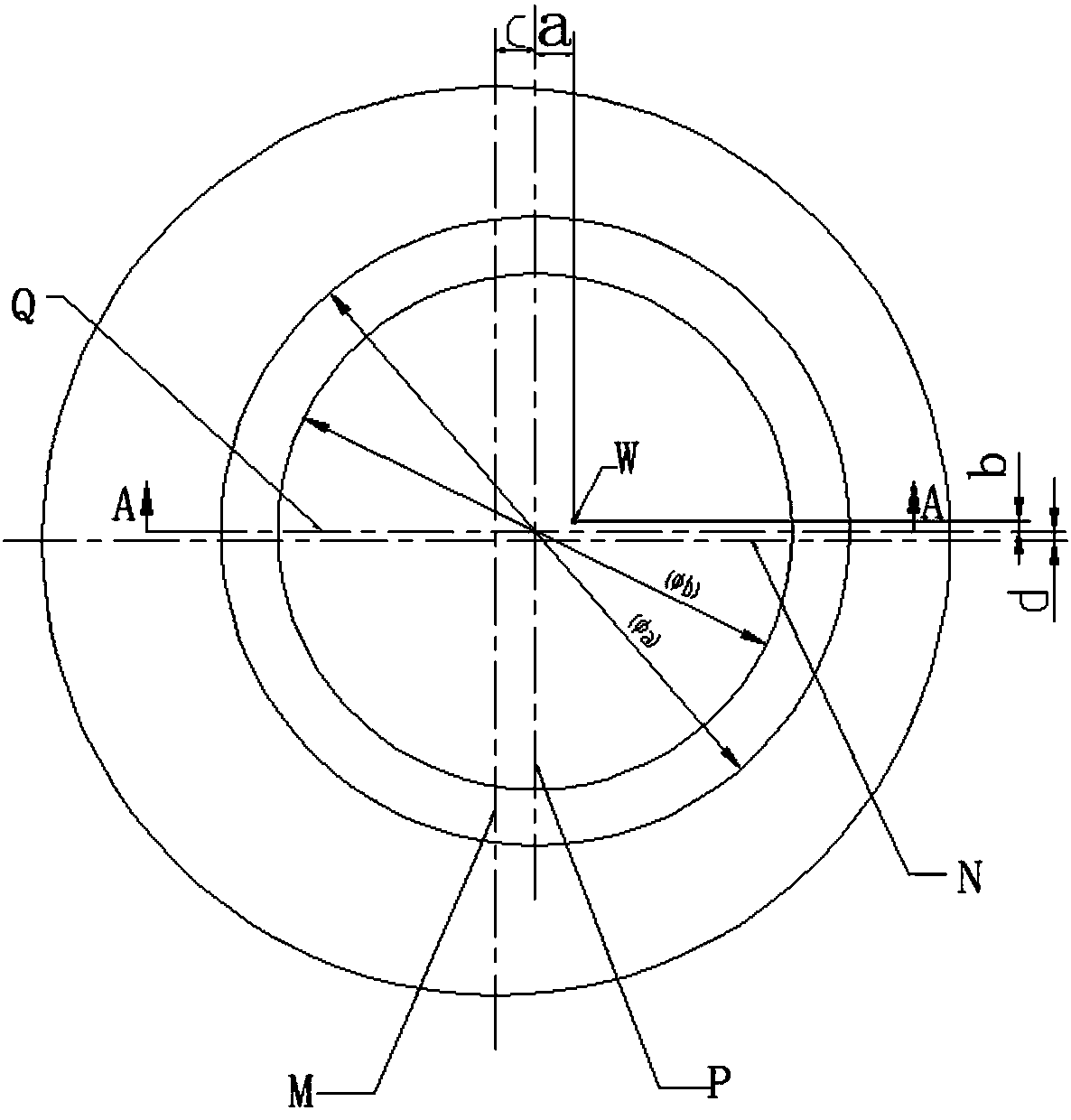

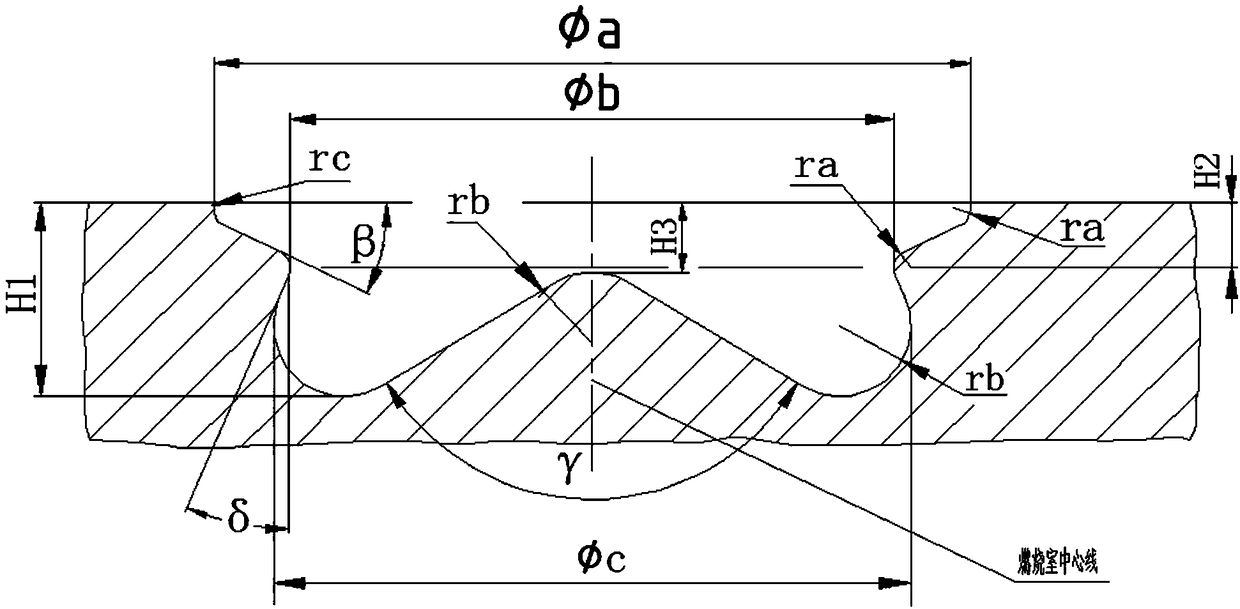

[0023] Such as Figure 1-3 Shown, a kind of piston combustion chamber structure is characterized in that, provides a kind of piston combustion chamber structure, is characterized in that, comprises piston 1, and the center line of piston is as figure 1 As shown, the upper part of the shallow basin type combustion chamber 2, when the piston moves up to near the top dead center, prevents the oil spray from splashing on the cylinder wall and the top surface of the piston; the upper part is a shallow basin type combustion chamber. A tumble flow is formed around the combustion chamber, which is helpful for mixing and combustion. The shallow basin type combustion chamber opening and the rounded corner R at the bottom can effectively avoid thermal stress.

[0024] The lower part of the ω-shaped combustion chamber 4, the two are combined by the position of the injector 3 and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com