Rock core drilling and sampling device under microgravity environment and sampling method

A sampling device and microgravity technology, applied in the direction of the sampling device, can solve the problems of drilling equipment pushing away from the surface, drilling failure, and difficulty in controlling the drilling direction, so as to improve sampling quality and efficiency, improve connection stability, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

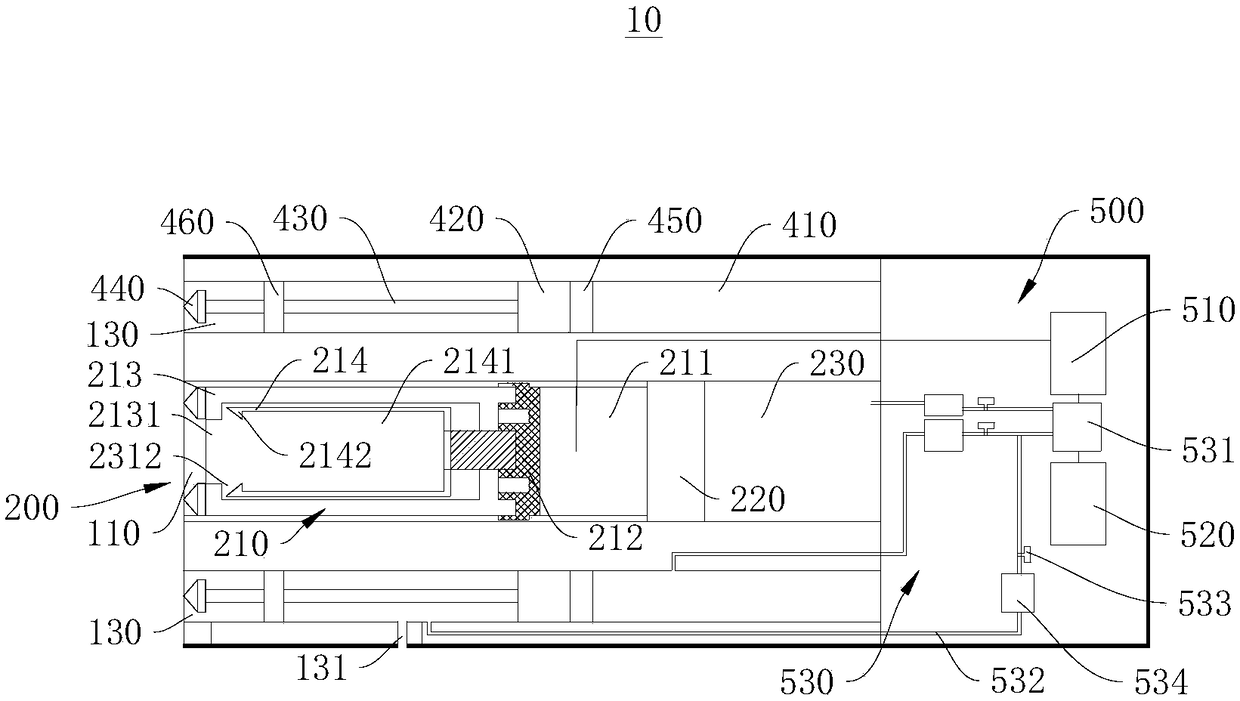

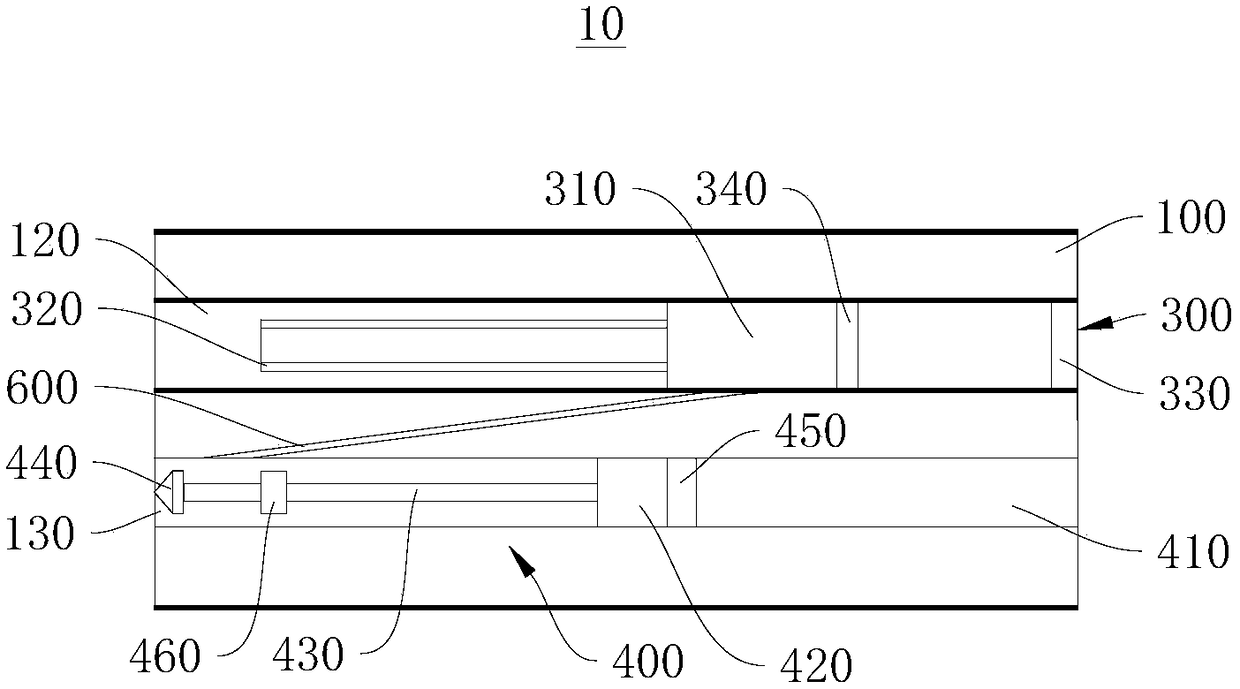

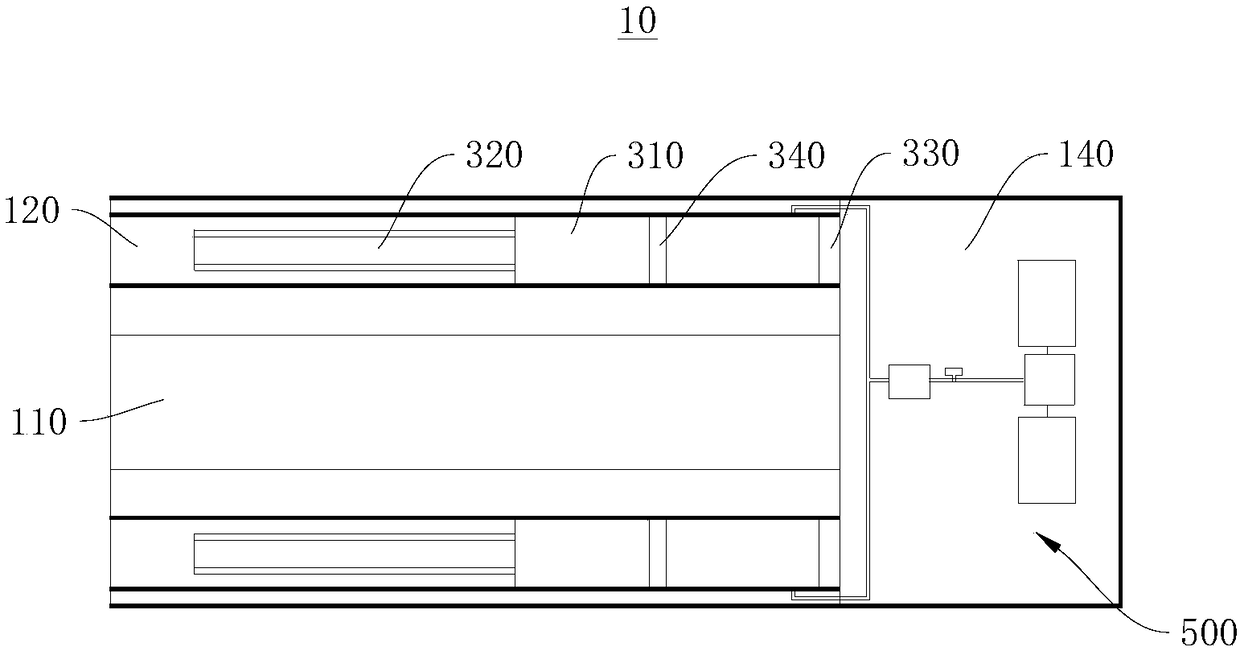

[0041] see figure 1 , In this embodiment, a device 10 for sampling a rock mass in a microgravity environment is provided, which is used for sampling a rock mass in a microgravity environment. In addition, the rock mass core sampling device 10 can efficiently sample rock mass samples in the microgravity environment, and can simultaneously ensure the stability of the rock mass core drilling device 10 during sampling in the microgravity environment.

[0042] Please refer to figure 1 and figure 2 , the device 10 for core drilling of rock mass in a microgravity environment includes a carrying body 100 , a core drilling system 200 , a control system 500 , a plurality of glue injection systems 300 and a plurality of automatic bolt systems 400 . The core sampling system 200 , the control system 500 , the multiple glue injection systems 300 and the multiple automatic bolt systems 400 are all arranged inside the carrying body 100 , so that the core sampling system 200 and the control...

no. 2 example

[0067] see Figure 5 , a sampling method is provided in this embodiment, and the sampling method is applied to the rock mass drilling core sampling device 10 provided in the first embodiment in a microgravity environment. Moreover, the sampling method can efficiently perform sampling in a microgravity environment, and can ensure the stability of the rock core drilling sampling device 10 in a microgravity environment.

[0068] Among them, sampling methods include:

[0069] S101 , placing the bearing body 100 on the surface of the rock mass.

[0070] It should be noted that, when placing the carrying body 100 on the rock mass surface, the openings of the first accommodating cavity 110 , the plurality of second accommodating cavities 120 and the plurality of third accommodating cavities 130 need to face the The surface of the rock mass, so that the core drilling system 200 inside the first accommodating cavity 110 and the plurality of automatic bolt systems 400 inside the plura...

no. 3 example

[0083] A sampling system (not shown) is provided in this embodiment, and the sampling system adopts the rock core sampling device 10 provided in the microgravity environment provided in the first embodiment. The sampling system can efficiently perform the sampling work of rock mass samples in a microgravity environment, and can ensure the stability of the rock mass drilling core sampling device 10 in the microgravity environment during rock mass sampling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com