Laser scanning mechanism based on lens refraction

A technology of laser scanning and mirrors, which is applied in optics, optical components, instruments, etc., can solve the problems of difficult to achieve high-speed scanning, high cost, and difficulty in improving precision, and achieve fast high-frequency continuous scanning, low cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

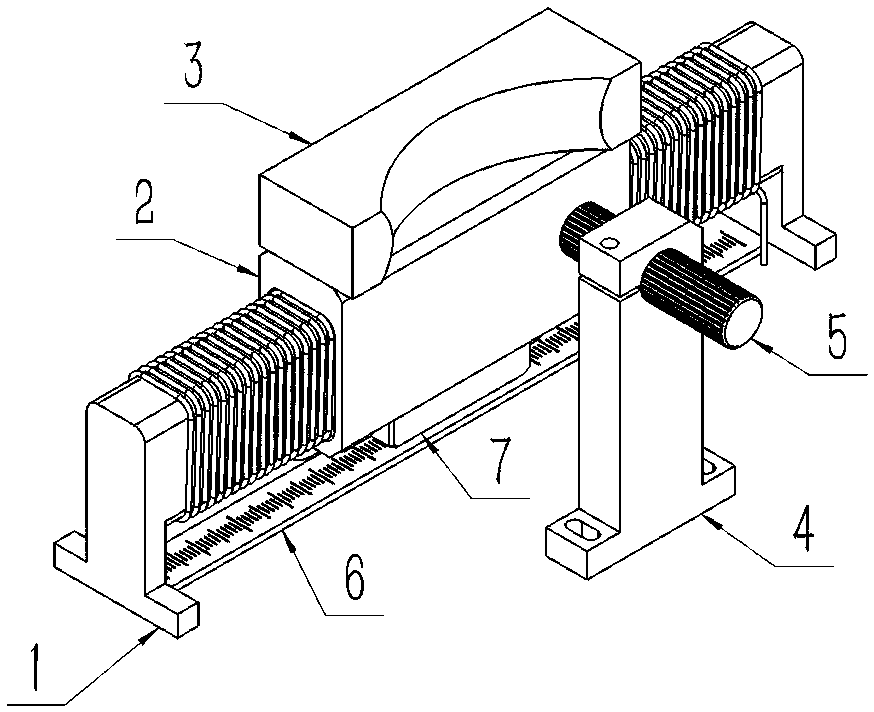

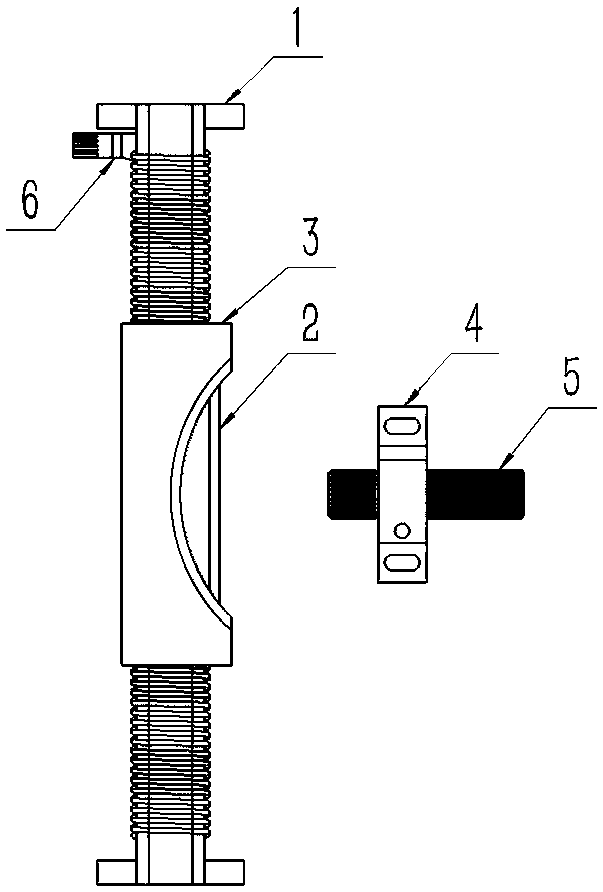

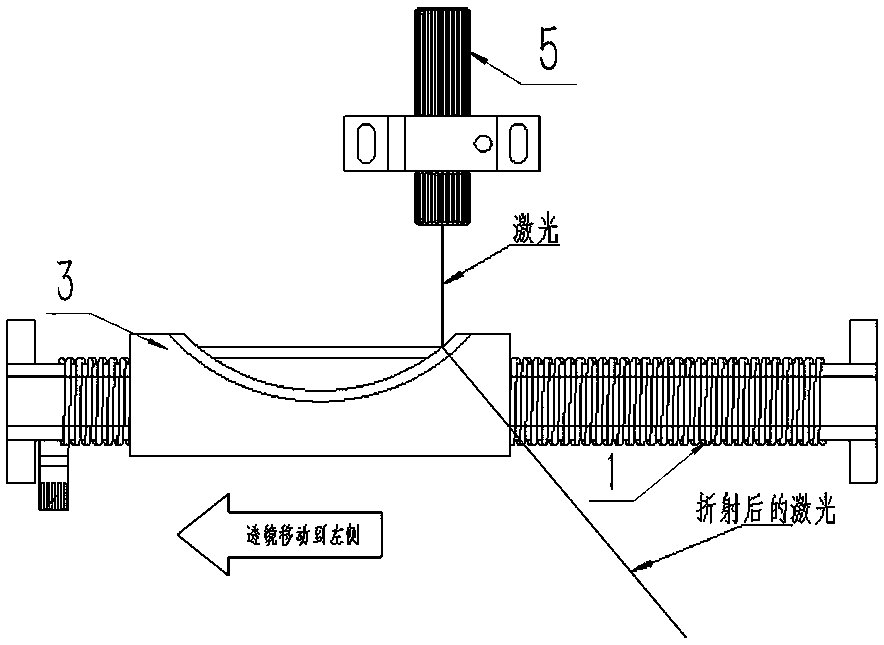

[0030] refer to Figure 1 to Figure 12 , a laser scanning mechanism based on lens refraction involved in the present invention, including a light source 5, a refracting lens 3, and a moving assembly; the light source 5 is fixed on the light source fixing seat 4, and the moving assembly includes a fixed voice coil motor stator 1 and a movable voice coil motor mover 2 arranged on the voice coil motor stator 1, the refracting lens 3 is fixed on the voice coil motor mover 2 and moves with the voice coil motor mover 2.

[0031] Specifically, in the present invention, the side of the refracting lens 3 facing the light source 5 has a concave laser incident area, and the surface of the laser incident area is a convex arc surface, which is convenient for light focusing. The laser incident area can be It is an arc-shaped concave structure, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com