Special compound premix for egg-laying hens producing pink-shell eggs at egg-laying period

A technology of compound premix and laying period, which is applied in application, animal feed, animal feed, etc., can solve the problems of unstable egg laying peak, high nutrient concentration and low feed intake, so as to improve digestion utilization rate, The effect of enhancing metabolism and increasing egg production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific implementation mode 1 Preparation of special compound premix for powder-shell laying hens during laying period

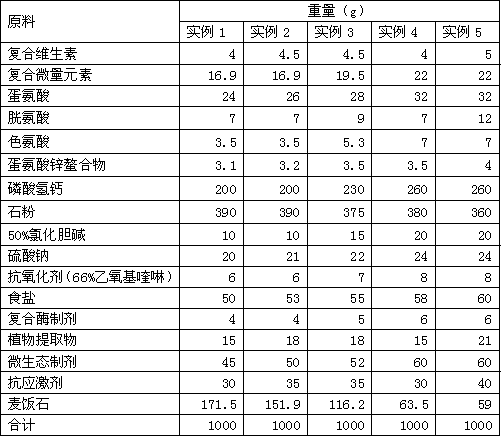

[0018] Table 1 Preparation of special compound premix for laying period of powder-shell hens

[0019]

[0020] The preparation of table 2 multivitamin

[0021] raw material

Weight (g)

VA (500,000 IU / g)

65

VD 3 (500,000 IU / g)

30

VE (500 IU / g)

240

50% VK 3

18

99%VB 1

11.1

80%VB 2

33.9

99%VB 6

15.3

1%VB 12

9

2% biotin

38.4

99% Niacin

147

95% folic acid

5.25

90% calcium pantothenate

54

Antioxidant (33% Ethoxyquinoline)

12.6

Rice husk powder (carrier)

320.45

total

1000

[0022] The preparation of table 3 compound trace elements

[0023] raw material

Weight (g)

Basic copper chloride (copper≥60%)

13.4

Ferrous sulfate monohydrate (iron ≥ 30%)

1...

specific Embodiment approach 2

[0027] Specific implementation mode 2 Preparation of full-price feed for laying hens

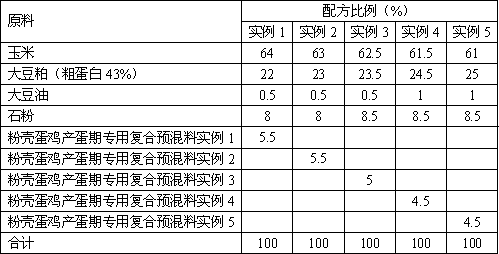

[0028] Table 4 Preparation of full-price feed for laying hens with powder shells

[0029]

specific Embodiment approach 3

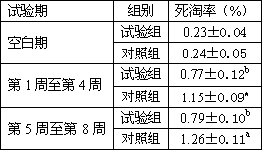

[0030] Specific implementation mode 3 Feeding effect evaluation of special compound premix for powder-shell laying hens during laying period

[0031] Using the formula of the full-price feed example 3 in the specific embodiment 2, the feeding effect of the special compound premix example 3 for the laying period of the powder-shell layer and the 5% compound premix for the laying period of the conventional laying hen in the market were compared. The full-price feed formulas of the control group and the test group are shown in Table 6.

[0032] Table 5 Labeled amount of active ingredients in commercially available 5% laying hen premix

[0033] Active ingredients

Commercially available 5% laying hen premix

Vitamin A, KIU≥

180

Vitamin D3, KIU≥

54

Vitamin E, IU≥

360

Vitamin K3,mg≥

56

Vitamin B1,mg≥

40

Vitamin B2,mg≥

100

Vitamin B6,mg≥

22

Vitamin B12,mg≥

0.72

Biotin,mg≥

0.08

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com