Spiral-wound membrane element

A roll-type membrane and element technology, applied in membrane technology, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve the problem of desalination rate, water flux and pollution resistance of membrane elements, and shorten membrane service life , the reduction of water flow line speed and other problems, to achieve the effect of improving anti-pollution performance, prolonging service life and increasing water flow line speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] For the convenience of those skilled in the art to understand, the following will further limit the technical solution of the present invention in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the description.

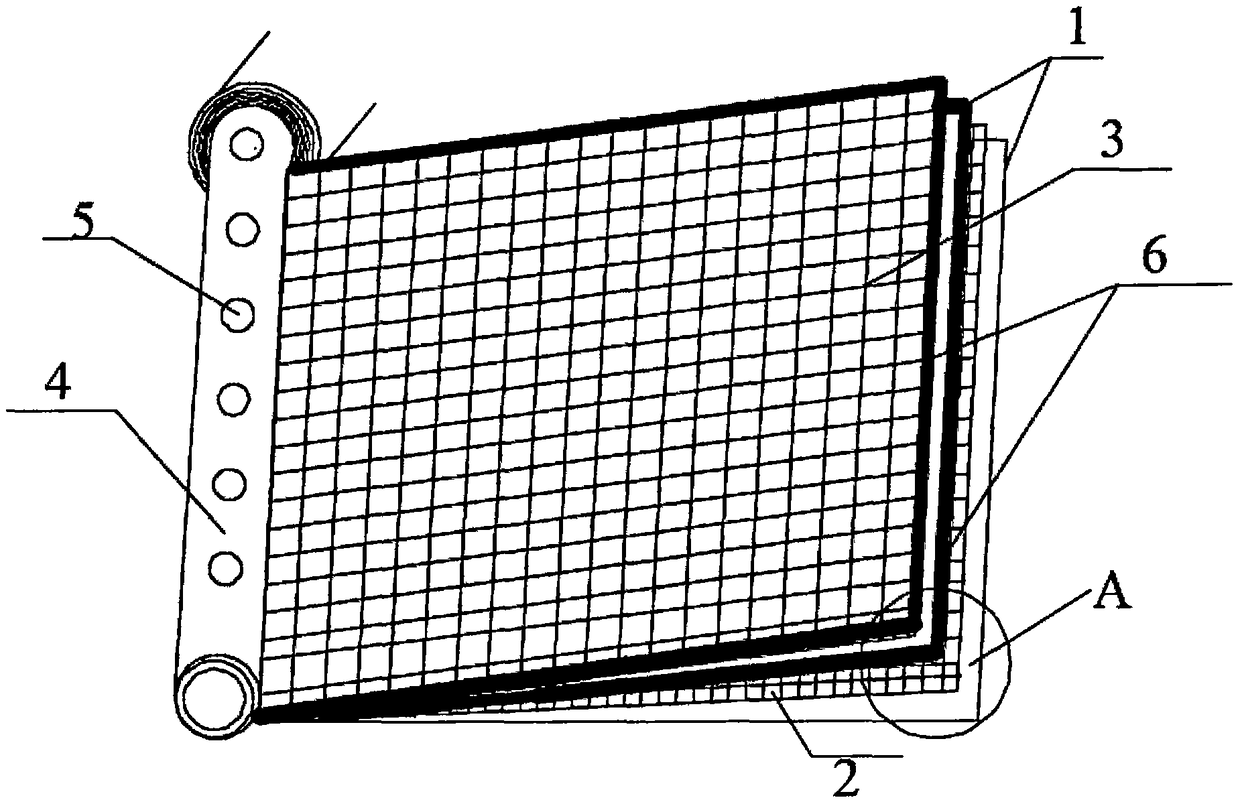

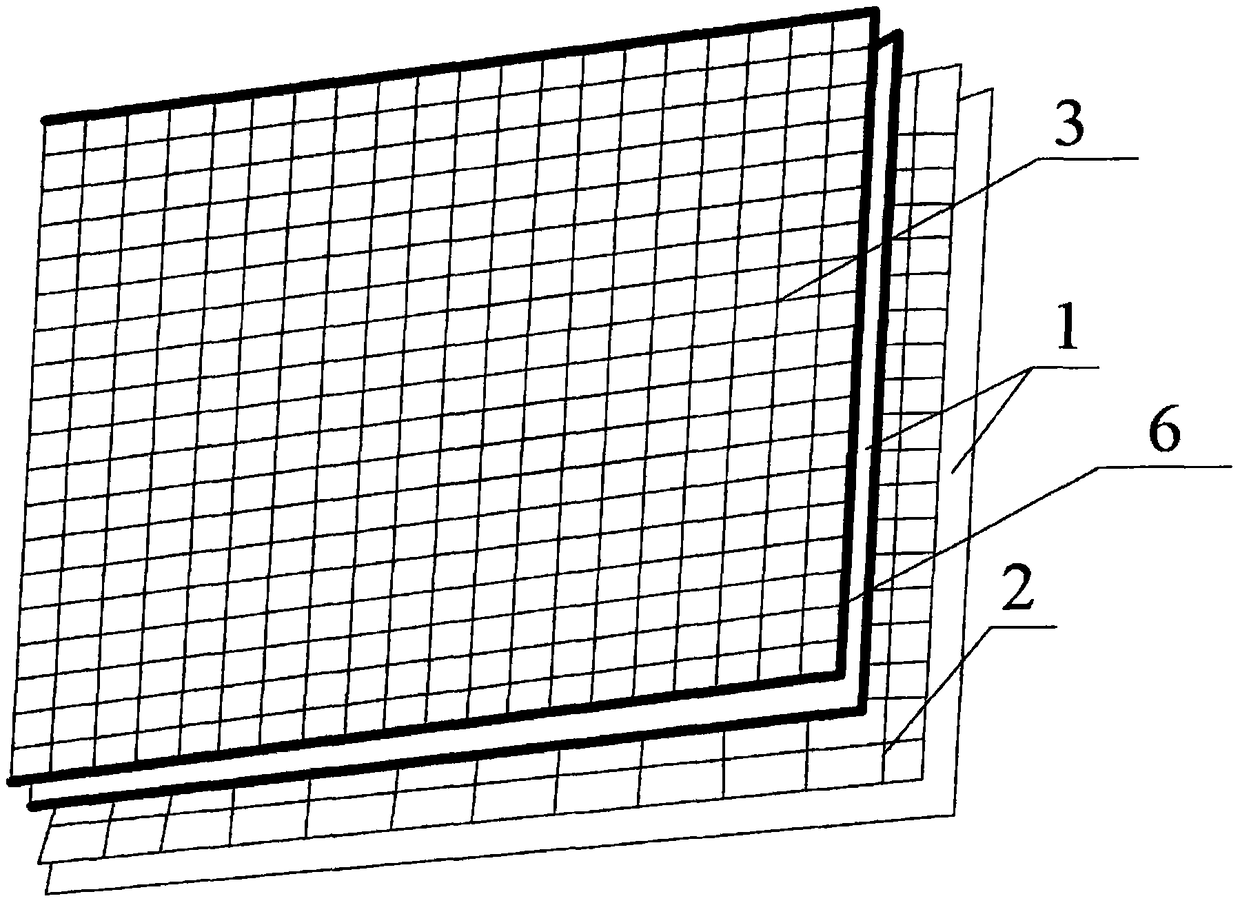

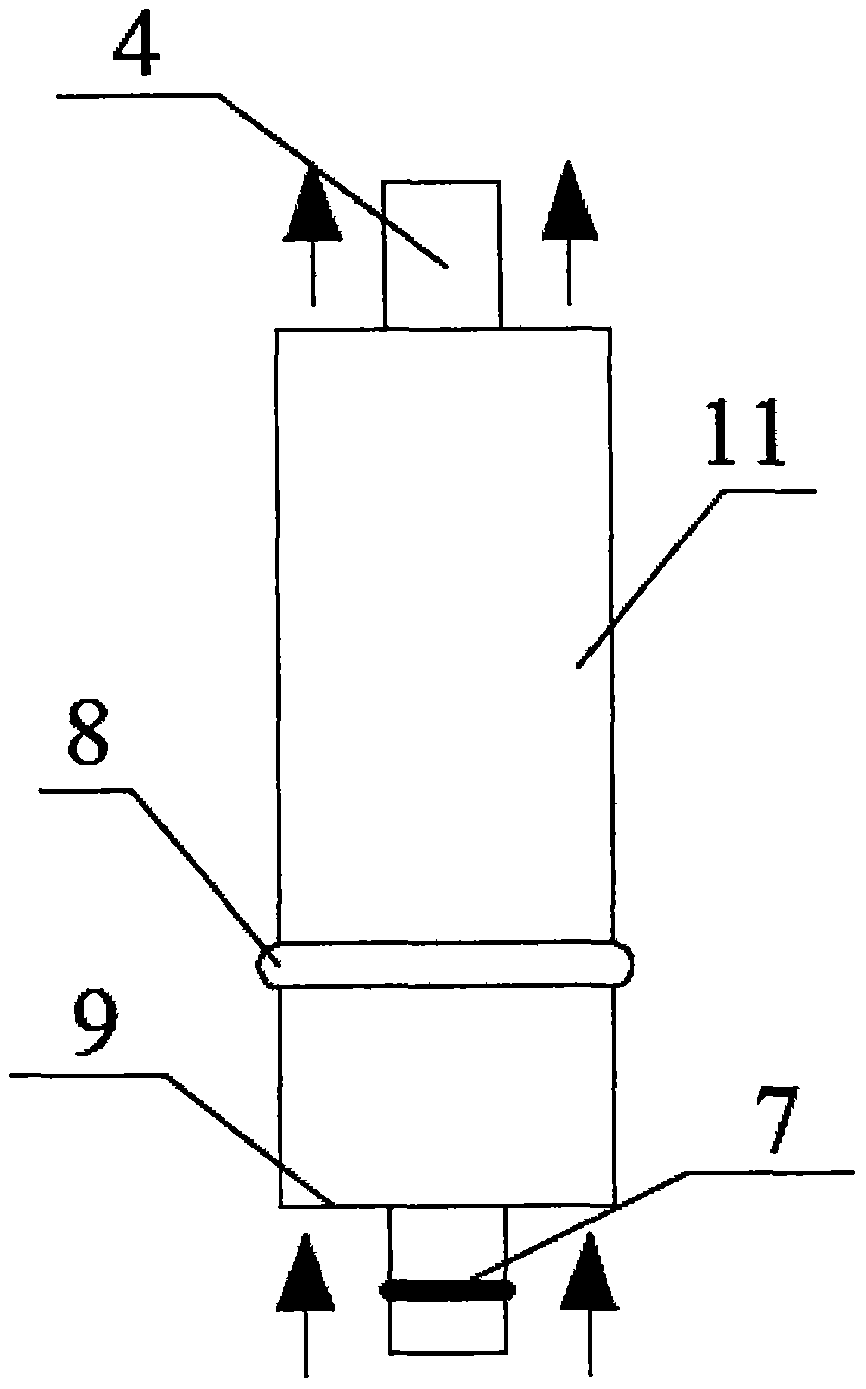

[0023] Such as Figures 1 to 5 As shown, a roll-type membrane element includes a separation diaphragm 1, a raw water diversion net 2, a produced water diversion net 3, a central water collection pipe 4 and an adhesive 6; the separation diaphragm 1 is a sheet-shaped high-precision Filtration membrane, the sheet-shaped high-precision filtration membrane is a reverse osmosis membrane, or a nanofiltration membrane, or an ultrafiltration membrane, one side of the separation membrane 1 is adjacent to the raw water diversion network 2, and the other side is adjacent to The water production diversion net 3, the separation diaphragm 1, the raw water diversion net 2 and the water production diversion net...

Embodiment 2

[0028] The roll-type membrane element of this embodiment is basically the same as that of Embodiment 1, except that the thickness of the raw water diversion net 2 near the raw water inlet end 9 is 0.6 mm, and the thickness near the concentrated water discharge end is 10 has a thickness of 0.2mm; the permeated water diversion net 3 has a thickness of 0.10mm near the raw water inlet 9, and a side near the concentrated water discharge 10 has a thickness of 0.50mm.

[0029] Technical effect experiment: take the same type of membrane, the same length membrane using the experimental method of the present invention to roll membrane elements, at 0.41Mpa, 200ppm sodium chloride solution, 35% recovery rate conditions and common roll membrane elements The comparison experiment of clean water flux and desalination rate was carried out, and the results are as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com