A device for evenly distributing ore slurry

A technology of ore pulp and feeding pipe, which is applied in the direction of solid separation, etc., can solve the problems of reducing sorting accuracy and sorting efficiency, uneven feeding, interference of product material layer and sedimentation material layer, etc., so as to improve the separation accuracy and The effect of sorting efficiency, easy operation and control, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the protection scope of the present invention.

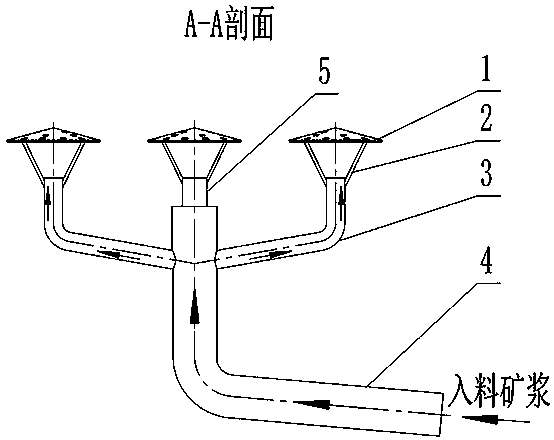

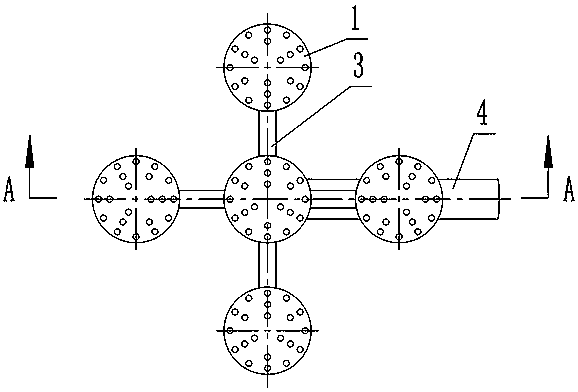

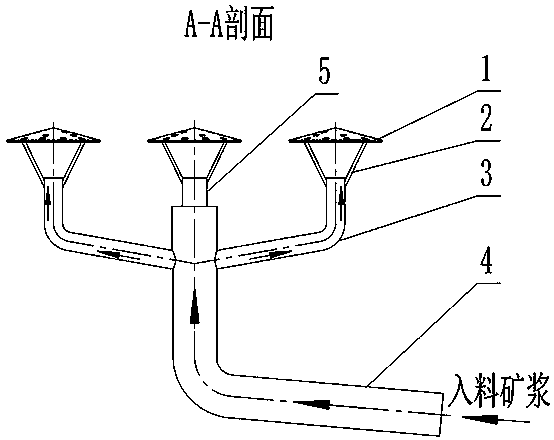

[0018] like figure 1 and figure 2 As shown, the pulp feeding and equalizing device in this embodiment includes a feeding pipe 4 , a branch pipe 3 , an umbrella cap 1 , an umbrella cap support 2 and a central discharge pipe 5 . The feeding pipe 4 is a steel pipe with a large diameter, and the branch pipe 3 is a steel pipe with a thin diameter. Arrangement, the outlet of the branch pipe 3 is on the same horizontal plane and the outlet is kept upward. The umbrella cap 1 adopts an umbrella-shaped structure surrounded by steel plates to form a certain cone angle. Several through holes are evenly distributed on the surface of the umbrella cap. The umbrella cap is connected to the branch pipe 3 through the umbrella cap support 2. The top of the vertical pipe section of the feeding pipe 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com