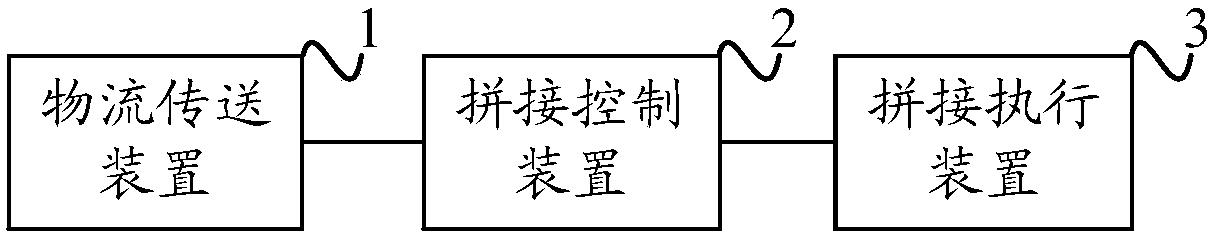

BIM-based wallboard component reinforcing steel bar splicing system and method

A steel bar and component technology, applied in the field of BIM-based steel bar assembly system for wall panels, can solve the problems of low steel bar processing efficiency, achieve the effect of less manual intervention, meet the development trend, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

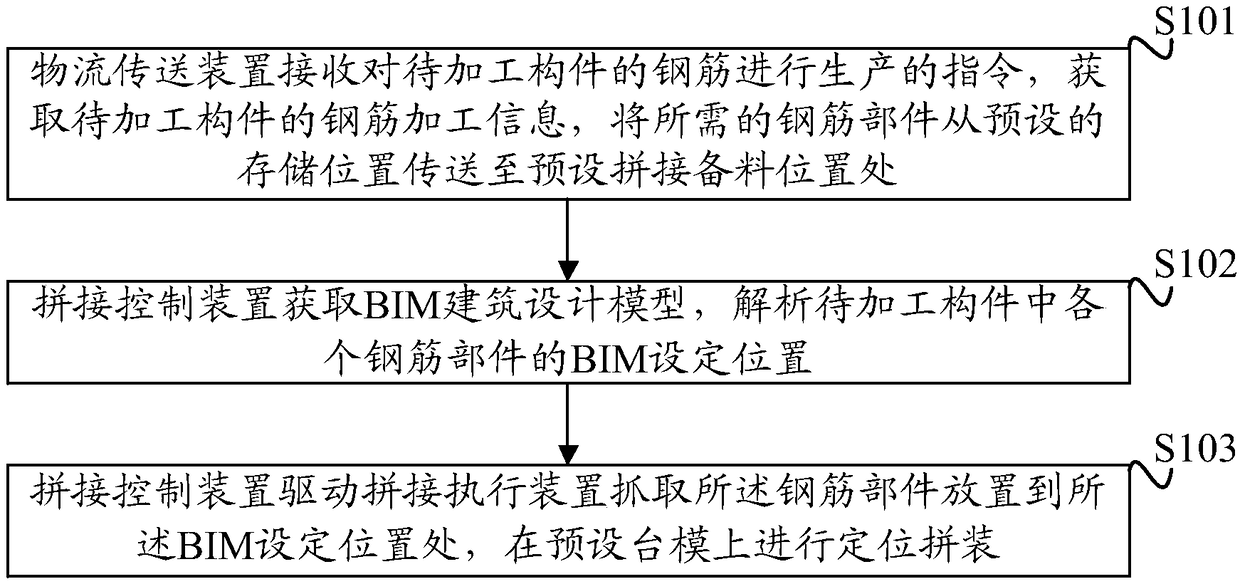

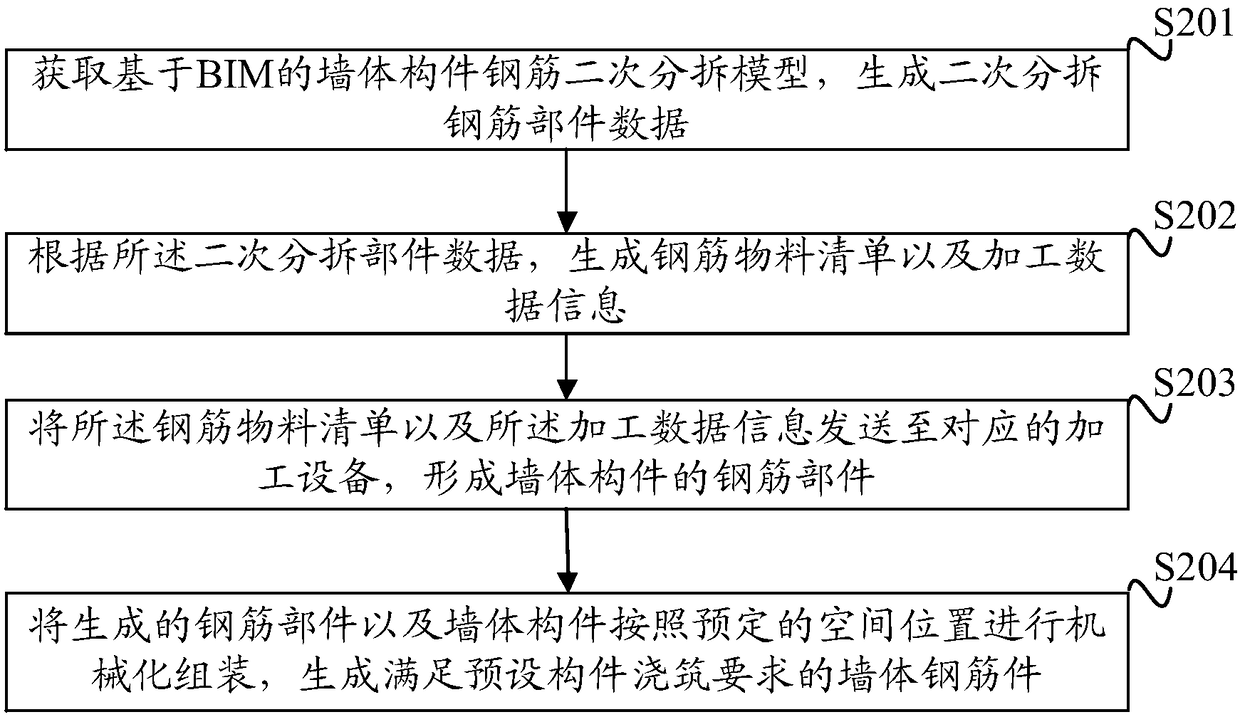

Method used

Image

Examples

specific Embodiment approach

[0059] As a specific embodiment, the BIM-based wall panel component reinforcement method provided by the present invention may also include:

[0060] The stirrup bending machine obtains the stirrup processing information of the BIM architectural design model, and processes the original reinforcement according to the stirrup part formed by the reinforcement cage to generate the stirrup;

[0061] The welding forming machine will weld the generated stirrups and transverse main reinforcement according to the preset position to generate a reinforcement cage;

[0062] The mesh welding machine obtains the steel mesh sheet processing information of the BIM architectural design model, and welds the steel mesh sheet in the component to be processed.

[0063] Further, the embodiments of the present invention may also include:

[0064] The logistics conveying device transmits the produced steel cage and the steel mesh to the corresponding three-dimensional storage location, and updates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com