Composite floor and its processing method

A processing method and technology for composite flooring, applied in the field of flooring, can solve the problems of low bonding strength between surface decoration layer and plywood base material, poor scratch resistance of composite flooring, easy generation of air bubbles on the board surface, etc., to achieve good curing effect, avoid board Foaming, not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

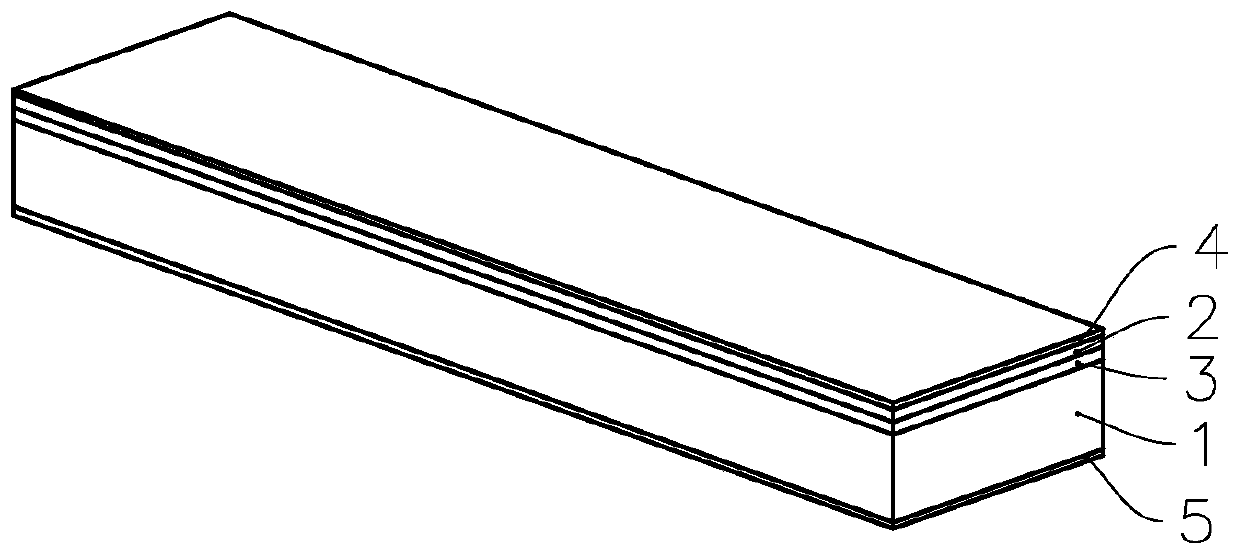

[0019] See figure 1 , figure 1 It is a structural diagram of an embodiment of the composite floor of the present invention. The composite floor of the present invention includes a base material layer 1 and a decorative surface layer arranged on the front surface of the base material layer. Among them, the base material layer 1 is made of multilayer plywood, and the decorative surface layer includes a wear-resistant layer 2 and a color film layer 3, plywood and color film. The film layers 3 are connected by an adhesive, and the surface of the wear-resistant layer 2 is provided with a paint protection layer 4, and the paint protection layer is one of UV light curing paint, scratch-resistant paint, geothermal paint or negative ion paint. A protective layer 5 is provided on the back of the plywood, and the protective layer 5 is one of UV light curing paint, balance paper, PE moisture-proof film, EVA static mat or aluminum foil. For the convenience of paving, tenons and grooves (n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com