Brake drum high-temperature alarm rapid cooling system

A rapid cooling and cooling system technology, applied in the direction of brakes, cooling brakes, transportation and packaging, etc., can solve problems such as tire burning, brake drum deformation, vehicle transportation safety hazards, etc., to speed up cooling speed, prolong service life, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

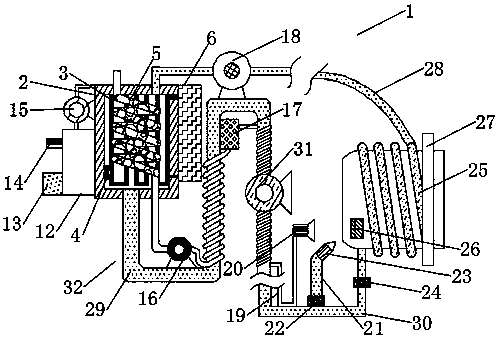

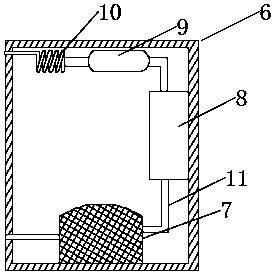

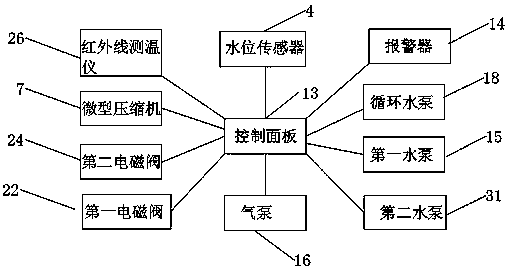

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a brake drum high temperature alarm rapid cooling system, including a cooling system body 1, the cooling system body 1 is composed of a cooling water tank 2, a spare water tank 12, a water pipe 32 and a cooling box 6 One side of the cooling water tank 2 is fixedly connected with a backup water tank 12, and the side of the backup water tank 12 away from the cooling water tank 2 is fixedly connected with a control panel 13 and an alarm 14, and the control panel 13 is located at the alarm 14, and the side of the cooling water tank 2 close to the backup water tank 12 is fixedly connected with a first water pump 15, and the first water pump 15 is located directly above the backup water tank 12, and the cooling water tank 2 is far away from the backup water tank 12 One side of the cooling box 6 is fixedly connected with a cooling box 6, and the bottom of the cooling box 6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com