Aeration device with stirring rods with gas outgoing holes

A technology of aeration device and stirring rod, which is applied in water aeration, biological treatment device, reflux water treatment, etc. It can solve the problems of poor stirring effect in aeration chamber, chaotic water flow, insufficient aeration of sewage, etc., and achieve aeration fuller effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

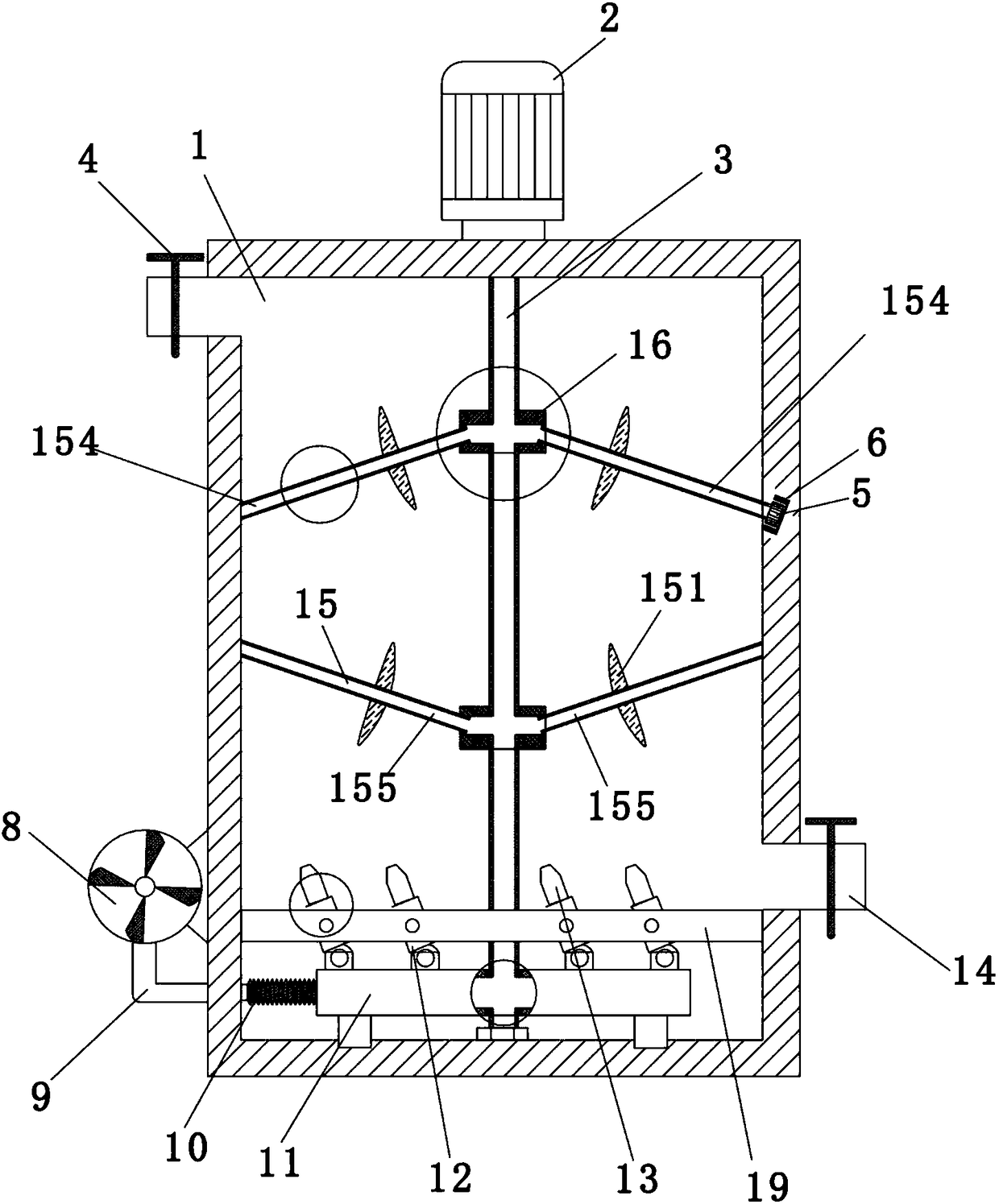

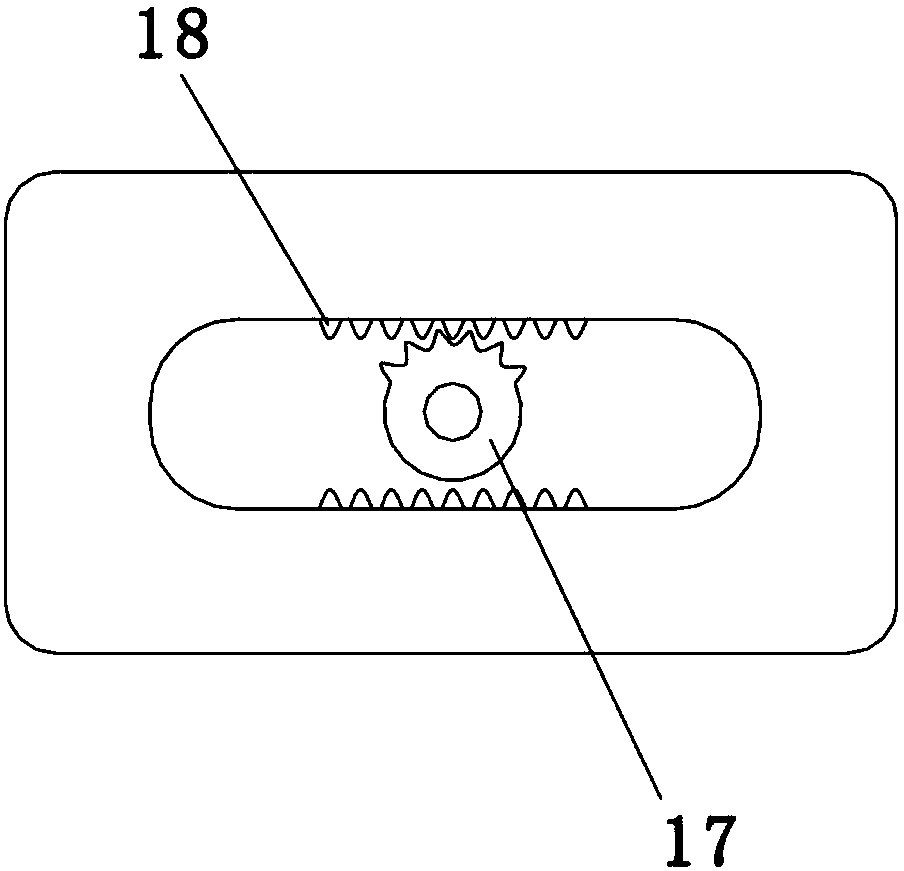

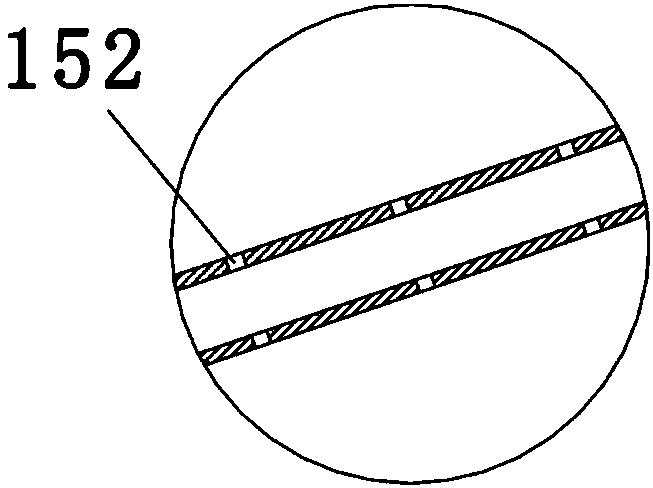

[0020] Such as Figure 1 to Figure 5 As shown, an aeration device with a stirring rod with an air outlet, including an aeration chamber 1, a motor 2 arranged on the top of the aeration chamber 1, a stirring module arranged inside the aeration chamber 1, and an aeration chamber 1 The aeration module at the bottom; the aeration module includes an air pump 8 arranged outside the aeration chamber 1 and an aeration pan 11 arranged at the bottom of the aeration chamber 1, and a telescopic tube is arranged between the aeration pan 11 and the air pump 8 10 connection, the aeration chamber 1 is isolated from the aeration module by a bottom plate 19, and the bottom plate 19 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com