Integrated hydrolysis acidification and anaerobic fermentation device

A technology of hydrolysis, acidification and anaerobic fermentation, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc. The effect of increasing land area, volume gas production rate and biogas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

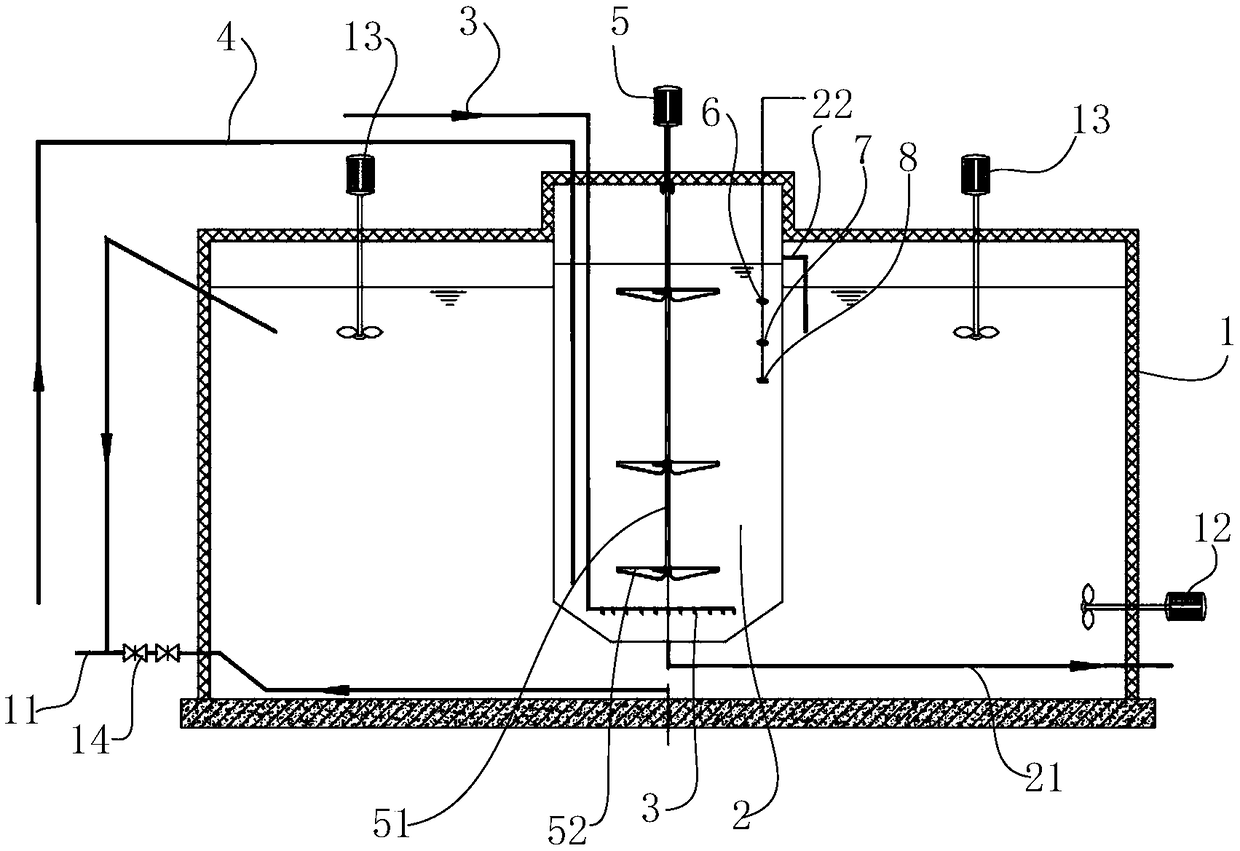

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The embodiments are only used to explain the present invention, but not to limit the scope of the present invention.

[0034] like figure 1 As shown, a hydrolytic acidification and anaerobic fermentation integrated device of this embodiment includes an anaerobic tank 1, a hydrolytic acidification tank 2, an aeration system and a feed system, and the hydrolysis acidification tank 2 is installed on the anaerobic In the tank 1, the hydrolysis and acidification tank 2 communicates with the inside of the anaerobic tank 1 through the overflow port at the upper end; the aeration system communicates with the bottom of the hydrolysis and acidification tank 2 through the aeration pipeline 3, and the feed The system communicates with the bottom of the hydrolysis acidification tank 2 through the feed pipeline 4 .

[0035] The hydrolytic acidification and anaero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com