Efficient treatment method for solid waste ion exchange resin

A technology of ion exchange resin and exchange resin, which is applied in the direction of solid fuel, waste fuel, biofuel, etc., can solve pollution and other problems, achieve the effect of solving environmental protection problems and reducing the cost of coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

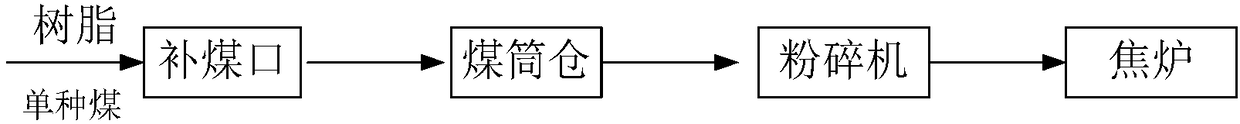

[0021] A method for efficiently treating solid waste ion exchange resins is completed in the following steps:

[0022] 1) Mix the solid waste ion exchange resin into the lean coking coal, the technical requirements for the solid waste ion exchange resin: Fe 2 o 3 Content≤50%, SiO 2 ≤50%, Ash≤10%, St,d≤0.5%. Control the input quality of waste solid ion exchange resin to be 0.05% of the total amount of lean coking coal;

[0023] 2) Put the lean coking coal mixed into the waste solid ion exchange resin into the pulverizer to pulverize and mix thoroughly;

[0024] 3) The mixed coal of solid waste ion exchange resin and lean coking coal is sent to the coal blending coking system, and the mass ratio of the mixed coal is 6.5%.

[0025] The use of solid waste ion exchange resin to remix coking does not affect the quality of coke, replaces the corresponding part of the amount of lean coking coal, and reduces the cost of coal blending. The average monthly remixing amount is 12 tons...

Embodiment 2

[0027] A method for efficiently treating solid waste ion exchange resins is completed in the following steps:

[0028] 1) Mix the solid waste ion exchange resin into the lean coal, the technical requirements for the solid waste ion exchange resin: Fe 2 o 3 Content≤50%, SiO 2 ≤50%, Ash≤10%, St,d≤0.5%. Control the input quality of waste solid ion exchange resin to 0.1% of the total amount of lean coal;

[0029] 2) Put the lean coal mixed into the waste solid ion exchange resin into the pulverizer to pulverize and mix thoroughly;

[0030] 3) The mixed coal of solid waste ion exchange resin and lean coal is sent to the coal blending coking system, and the mass ratio of the mixed coal is 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com