Device and method for installing and fixing profound hypothermia gaseous helium cold screen temperature sensor

A temperature sensor and fixing device technology, applied in the field of deep low temperature, can solve the problems of installation and transformation of temperature sensors that are not suitable for gas-helium cold screens, temperature sensor falling off, and difficulty in accurate temperature measurement, so as to eliminate the problem of temperature measurement deviation and reduce construction costs. Difficulty, reasonable structure and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

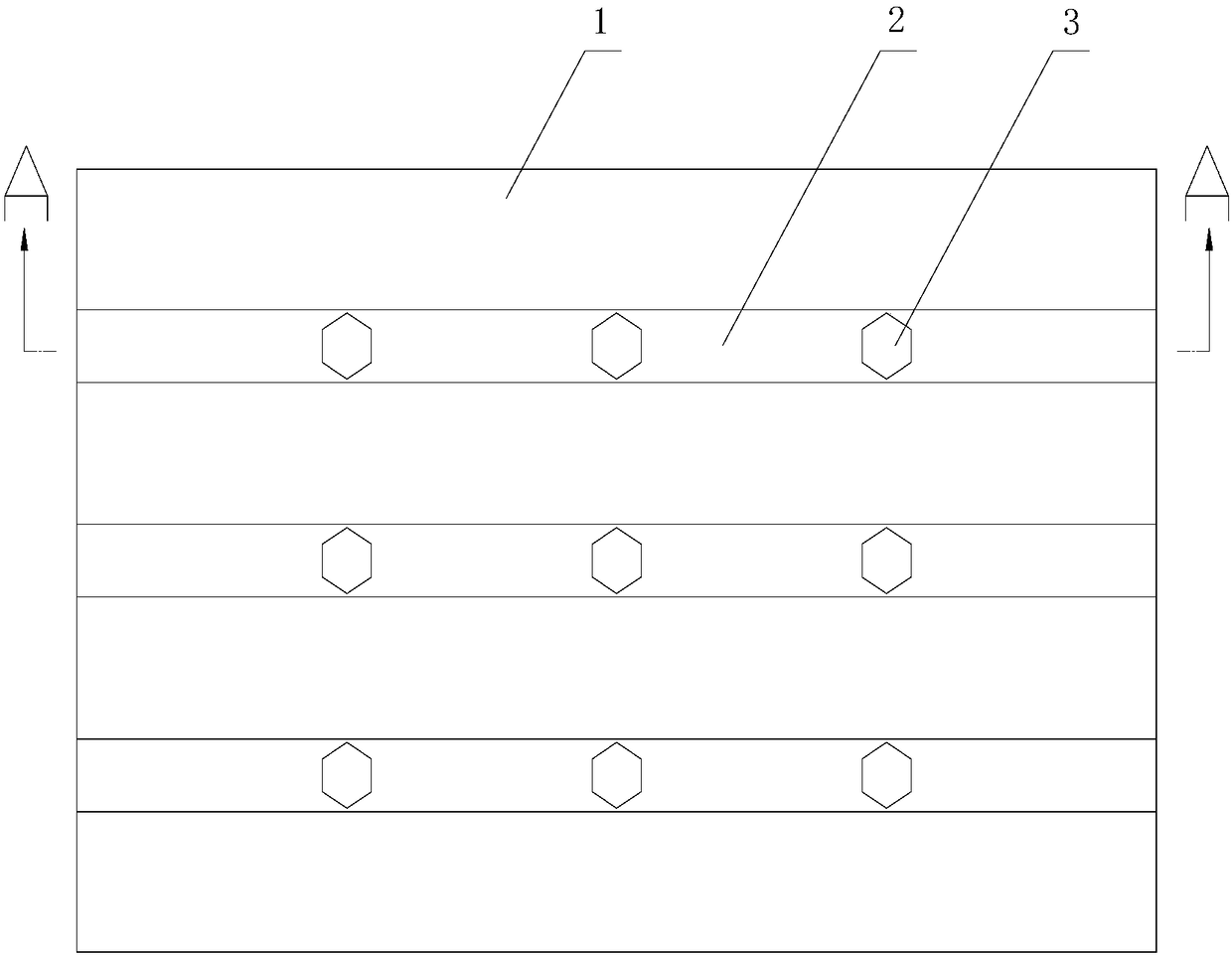

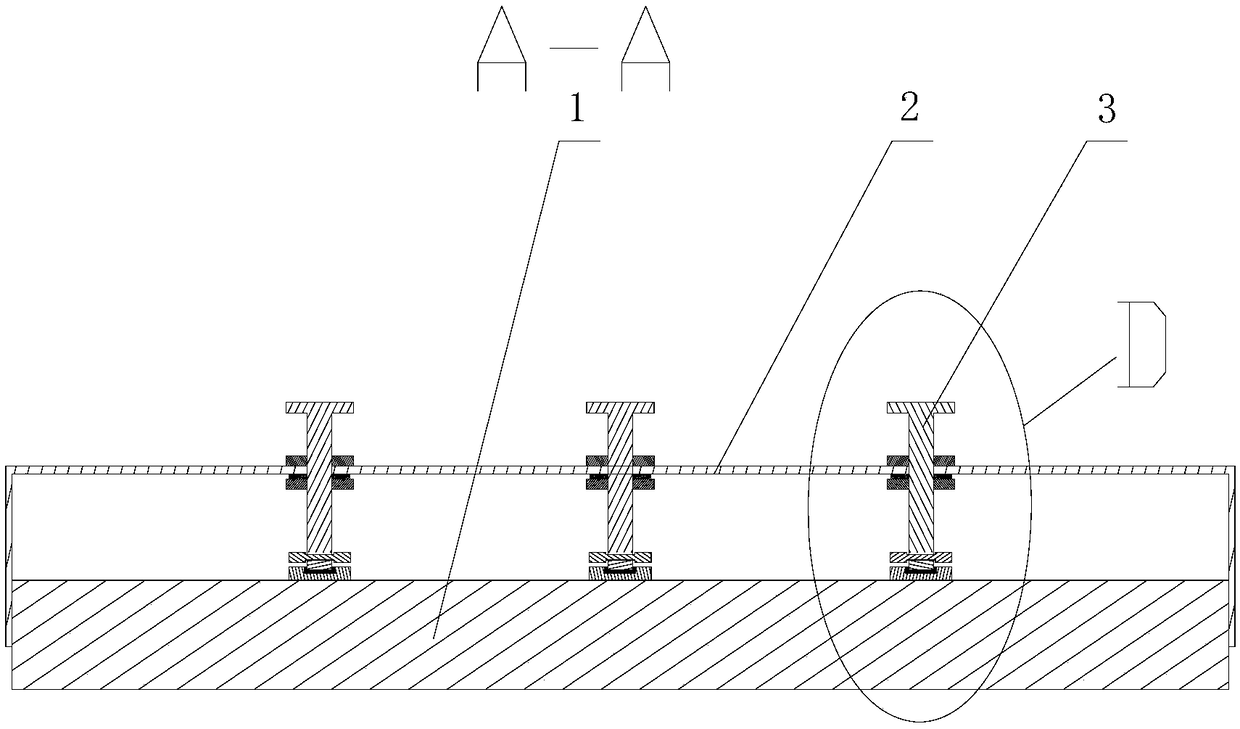

[0040] refer to figure 1 and figure 2 , the deep low temperature gas-helium cold screen temperature sensor installation and fixing device provided by the present invention includes a gas-helium cold screen 1, a mounting bracket 2, and a pressing device 3; wherein the mounting bracket 2 is installed on the outside of the gas-helium cold screen 1, and is pressed The device 3 is installed on the mounting bracket 2, and the end of the pressing device 3 is pressed against the gas-helium cold screen 1.

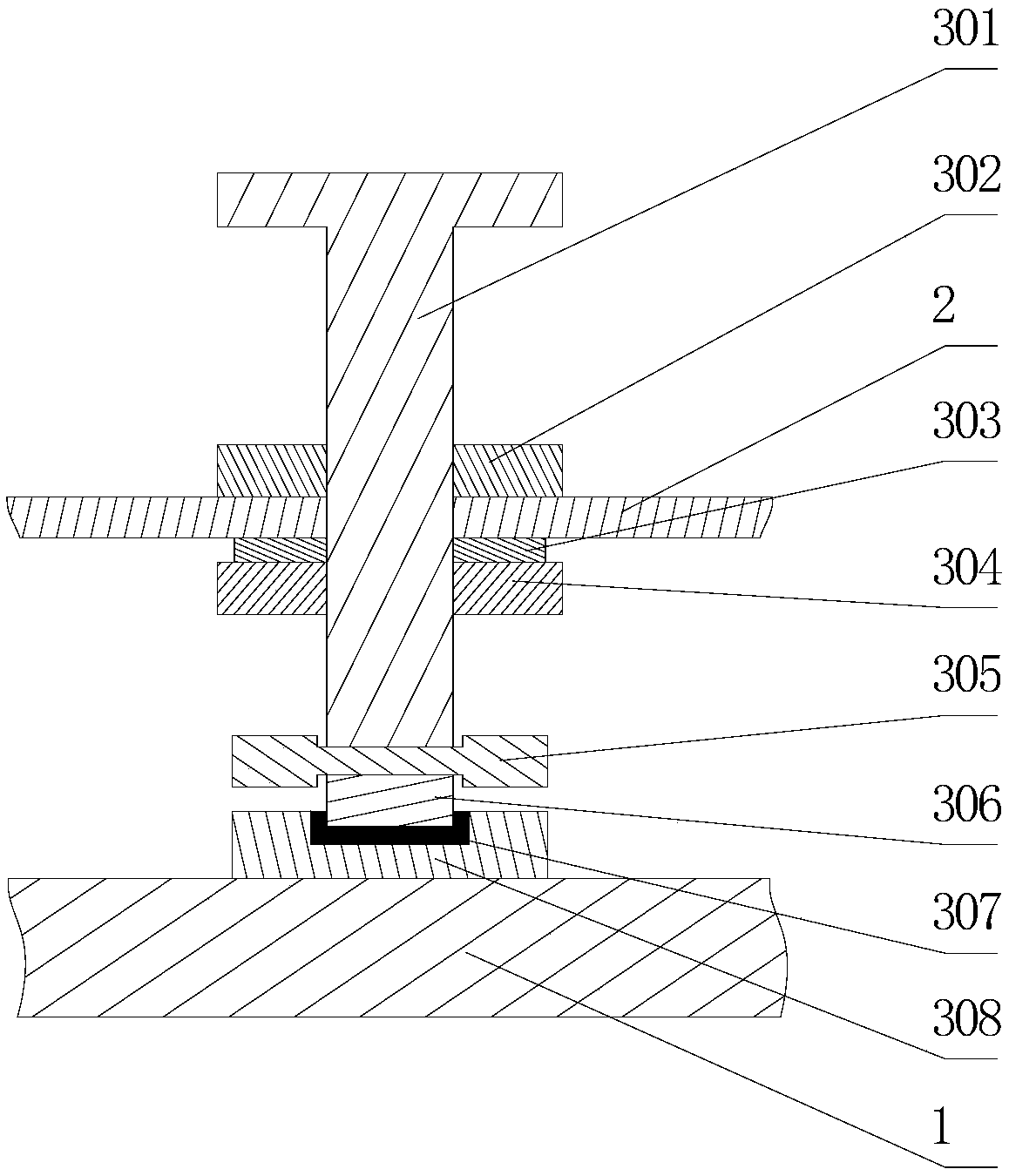

[0041] refer to figure 2 and image 3 , the compression device 3 includes an inlet compression bolt 301, a fixed nut 302, a spring washer 303, a locknut 304, a heat insulation pad 305, a temperature sensor 306, a filler 307, and a thermal pad 308; wherein, the thermal conductivity The spacer 308 is installed on the gas-helium cold screen 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com