Manufacturing method of back of RC-IGBT device

A manufacturing method and device technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low activation efficiency, large debris risk, expensive equipment, etc., to improve the activation degree, increase the product process cost, Fragmentation rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

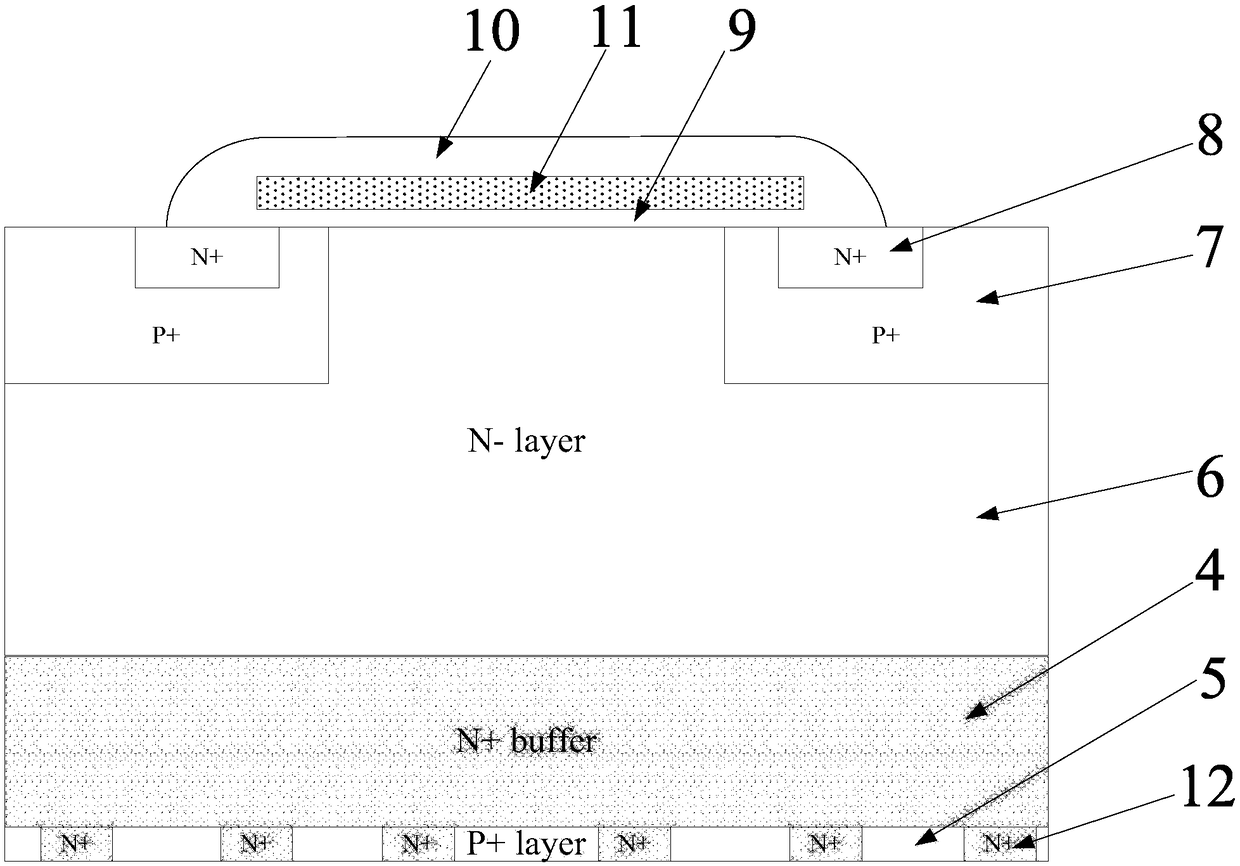

[0039] In the embodiment of the present invention, the method for fabricating the back surface of a planar gate RC-IGBT device is taken as an example for illustration, which is characterized in that it includes the following steps:

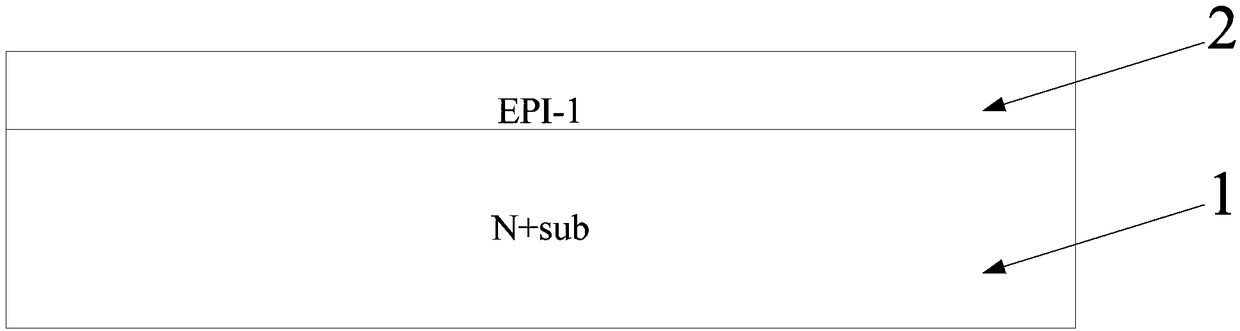

[0040] The first step: providing a semiconductor substrate, selecting an N-type semiconductor material as the semiconductor substrate 1, and the semiconductor substrate 1 is used as a support in the device manufacturing process;

[0041] like figure 2 As shown, the second step: on the semiconductor substrate 1, grow a first N-type epitaxial layer 2, the thickness of the first N-type epitaxial layer is 5-20 μm, and the resistivity is 40-100 ohm*cm;

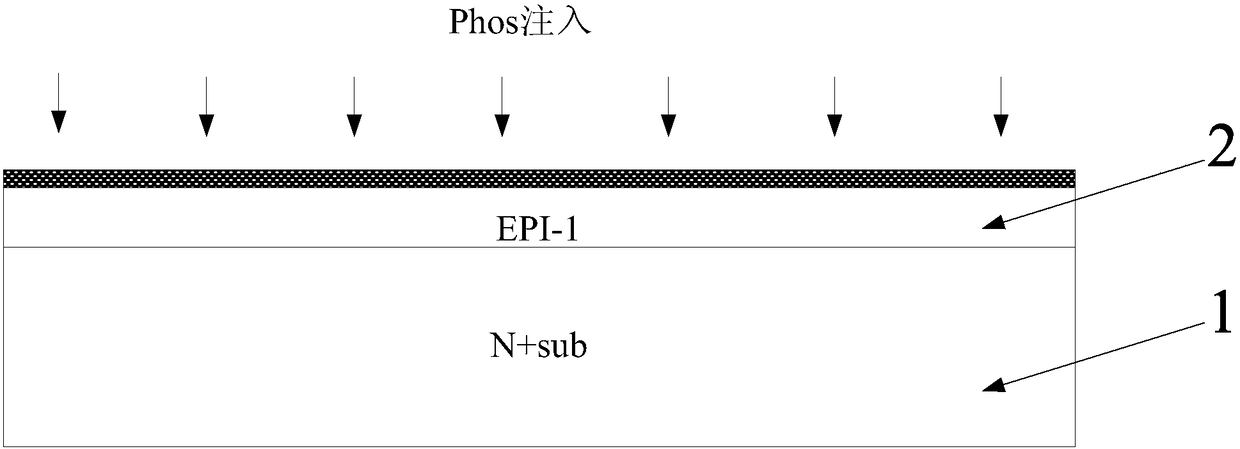

[0042] like image 3 As shown, the third step: implanting N-type impurities on the surface of the first N-type epitaxial layer 2, where the N-type impurity ions are phosphorus, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com