Variable pressure fluid volume control device and precise volume control method based on local constant pressure

A fluid and local technology, applied in packaging, liquid materials, packaging sterilization and other directions, can solve the problems of inability to change material pressure, inability to achieve high-precision and high-speed liquid product filling, etc., to improve filling speed and high filling speed Accuracy, the effect of ensuring filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

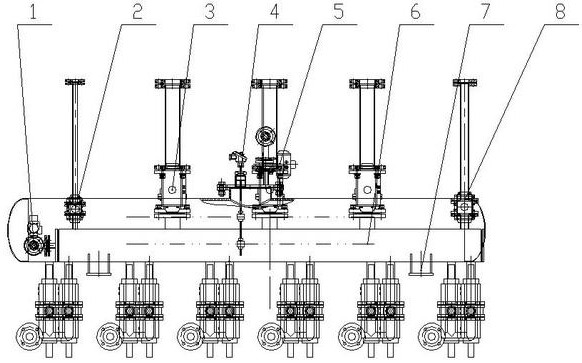

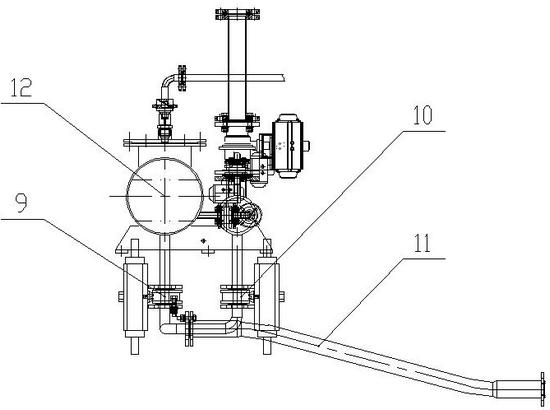

[0027] The invention provides a pressure-variable fluid volume control device based on local constant pressure, which specifically includes a pressure-stabilizing tank, a multi-way tank, a master control valve, a Unicom valve, a small valve, a large number of valves, an emptying valve, a purge valve, a cleaning Valves, level detection devices and tank holders.

[0028] The surge tank is in the shape of a cylinder, sealed at both ends, with a pressure resistance of 0.6 MPa, and a large flange is designed on the top to facilitate maintenance and repair. A liquid level detection device and an emptying valve are installed on the large flange cover. The liquid level detection device is used to control the liquid level of the material, and the emptying valve is used to release the pressure inside the surge tank. The emptying valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com