Device for producing yellow phosphorus through microwave method and production technology

A microwave method, yellow phosphorus technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high pollution and high energy consumption, achieve low corrosion, low energy consumption, eliminate gas escape and escape gas effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

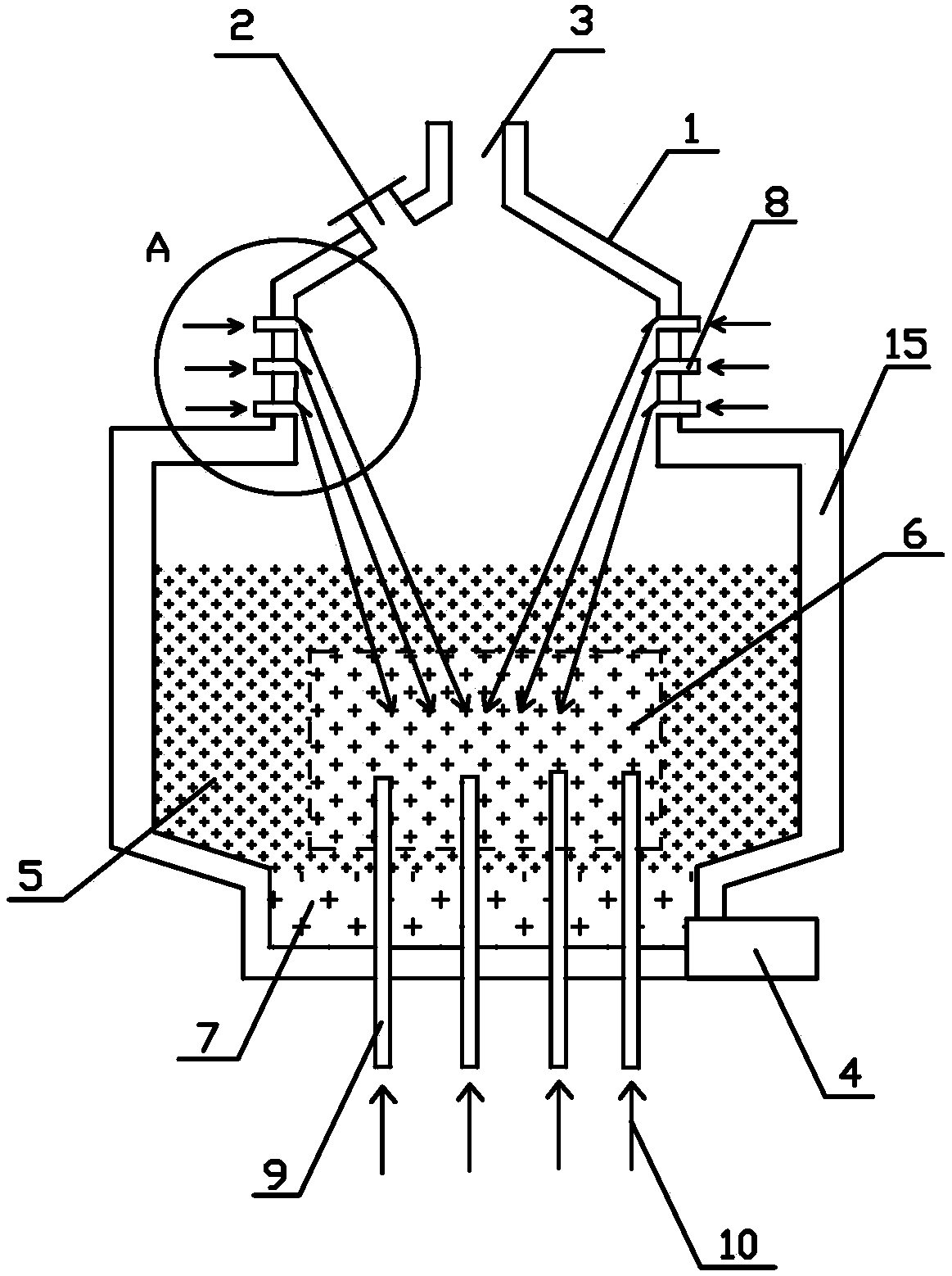

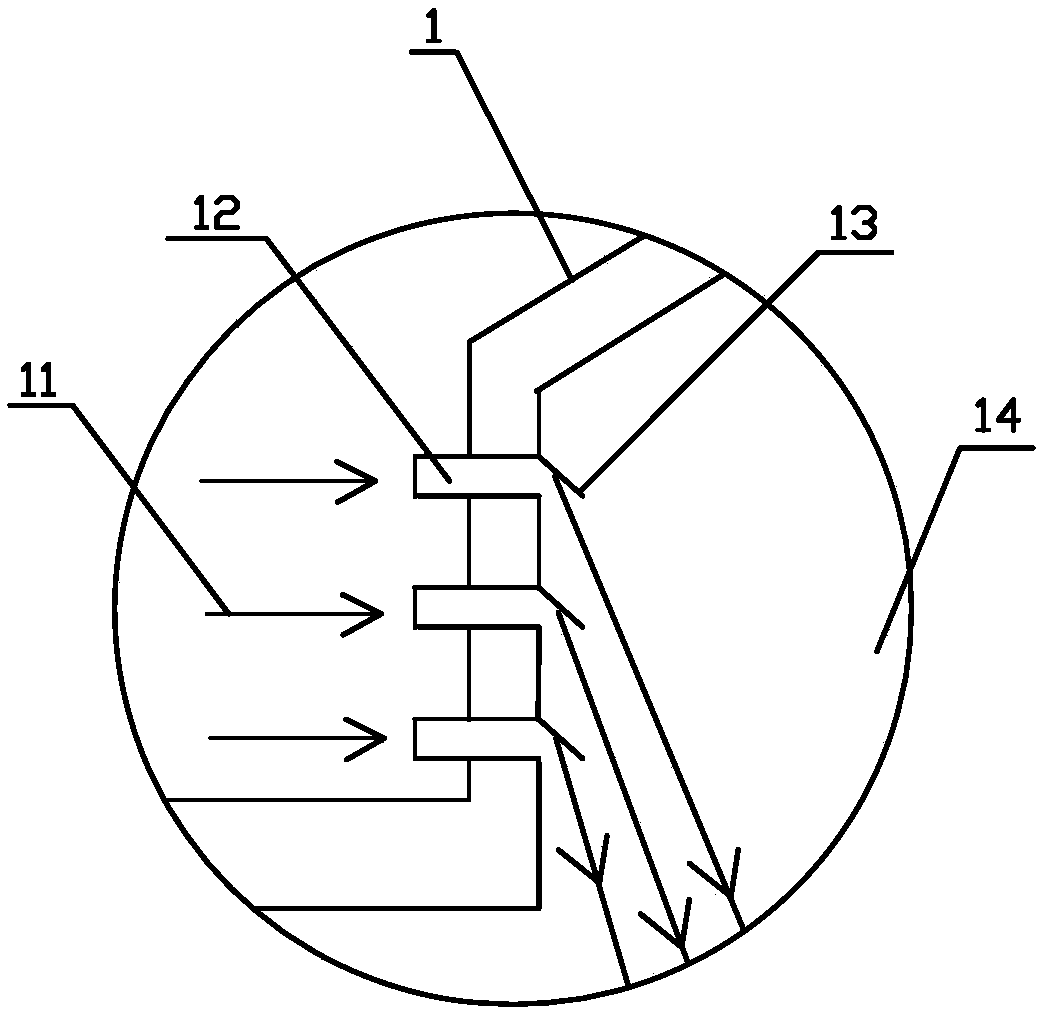

[0032] like Figure 1-2 As shown, a device for producing yellow phosphorus by microwave method includes a tank body 1 , a first microwave feeding assembly 8 and a second microwave feeding assembly 9 . The top of the tank body 1 is provided with a feed inlet 2 for putting in raw materials for preparation and an air outlet 3 for discharging yellow phosphorus vapor, and its bottom is provided with a discharge outlet 4 for discharging waste slag, and its inner cavity 14 is set as a micro At the same time, the side wall of the tank body 1 is divided into an outer wall, an inner wall and a vacuum insulation layer 15 between the outer wall and the inner wall, that is to say, the inner cavity 14 is in a closed micro positive pressure state. The inner cavity 14 is used to contain the raw materials for preparation and provide a reaction space for the raw materials. The first microwave feeding components 8 are used to feed microwaves 11 into the inner cavity 14, and the second microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com