Passivation method for high-resistance electroplated tin plate

A technology of electroplated tin plate and resistance, which is applied in the field of deep processing of steel, can solve problems such as sulfide spots, failure to isolate, and insufficient density of the passive passivation film of the resistance, so as to achieve the goal of improving resistance, coating quality and value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

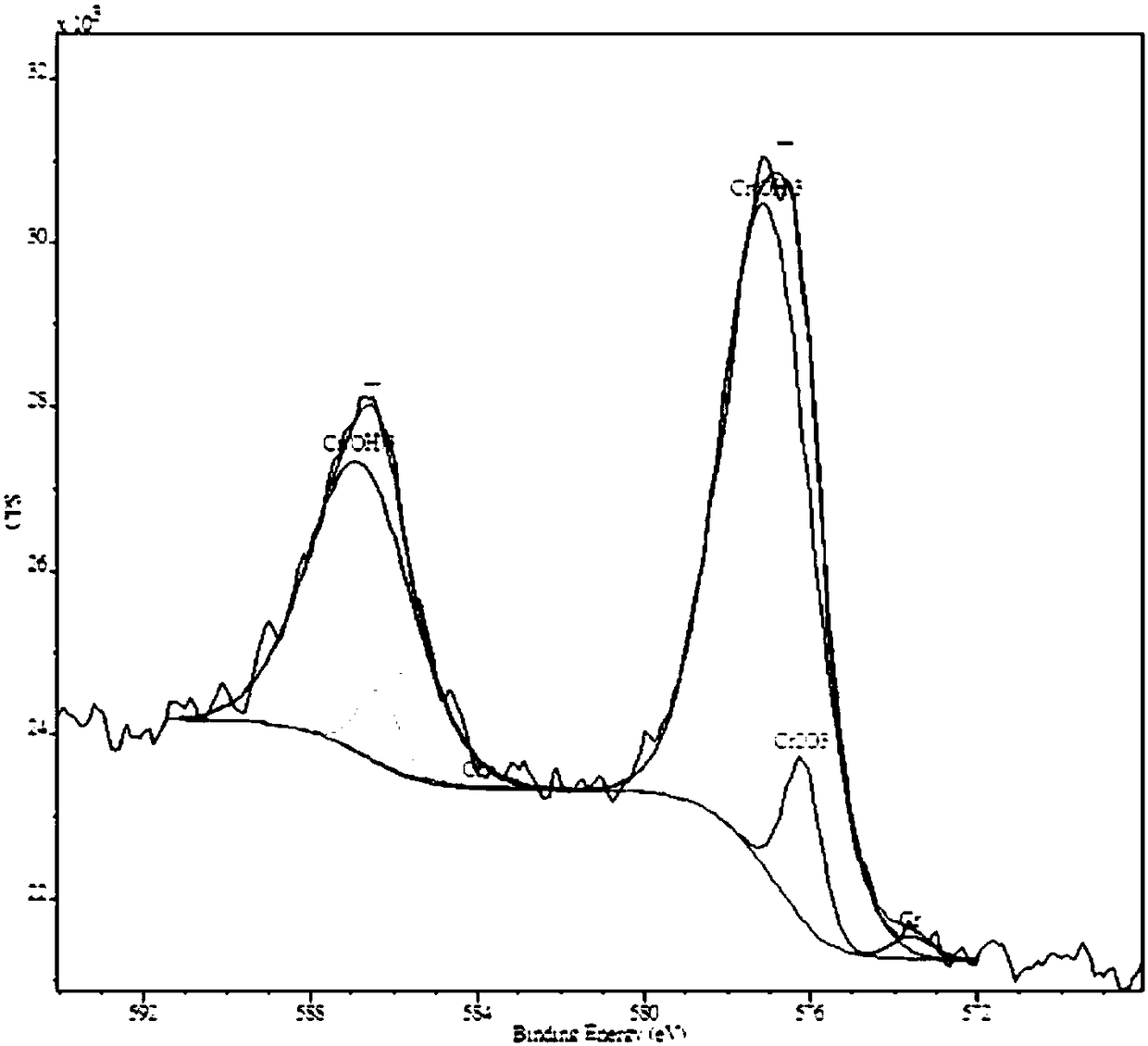

Image

Examples

Embodiment 1

[0026] The passivation method of the high-resistance tin-plated plate in this embodiment adopts a production process combining chemical passivation and electrochemical passivation, including the control of passivation solution, passivation temperature, passivation time, and passivation electric density. The process steps are as follows:

[0027] Put the electroplated tin plate before passivation into passivation tank A for chemical passivation, the passivation temperature is 48°C, the passivation solution is sodium dichromate, the concentration is 23g / L, and the pH value of the passivation solution is 4.8. The passivation time is 1.5 seconds.

[0028] After the chemical passivation is completed, continue to put the chemically passivated electrolytic tin plate into the passivation tank B for electrochemical passivation to obtain a highly resistant electrolytic tin plate. The passivation temperature is 48°C, and the passivation solution is heavy chromium. Sodium acid, the conce...

Embodiment 2

[0032] The passivation method of the high-resistance tin-plated plate in this embodiment adopts a production process combining chemical passivation and electrochemical passivation, including the control of passivation solution, passivation temperature, passivation time, and passivation electric density. The process steps are as follows:

[0033] Put the electroplated tin plate before passivation into passivation tank A for chemical passivation, the passivation temperature is 45°C, the passivation solution is sodium dichromate, the concentration is 19g / L, and the pH value of the passivation solution is 4.6. The passivation time was 1.3 seconds.

[0034] After the chemical passivation is completed, continue to put the chemically passivated electrolytic tin plate into passivation tank B for electrochemical passivation to obtain a highly resistant electrolytic tin plate. The passivation temperature is 45°C, and the passivation solution is heavy chromium. Sodium acid, the concentr...

Embodiment 3

[0038] The passivation method of the high-resistance tin-plated plate in this embodiment adopts a production process combining chemical passivation and electrochemical passivation, including the control of passivation solution, passivation temperature, passivation time, and passivation electric density. The process steps are as follows:

[0039] Put the electroplated tin plate before passivation into passivation tank A for chemical passivation, the passivation temperature is 45°C, the passivation solution is sodium dichromate, the concentration is 26g / L, and the pH value of the passivation solution is 5.0. The passivation time is 0.5 seconds.

[0040] After the chemical passivation is completed, continue to put the chemically passivated electrolytic tin plate into passivation tank B for electrochemical passivation to obtain a highly resistant electrolytic tin plate. The passivation temperature is 45°C, and the passivation solution is heavy chromium. Sodium acid, the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com