A method of making fish-scale textures on the surface of aluminum-magnesium alloys with laser

A technology of aluminum-magnesium alloy and surface fabrication, applied in the field of aluminum-magnesium alloy processing, can solve problems such as uneven surface material, inconsistent electrical conductivity, and decreased electrical conductivity, so as to simplify the quality inspection process, improve electrical conductivity, and product yield Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

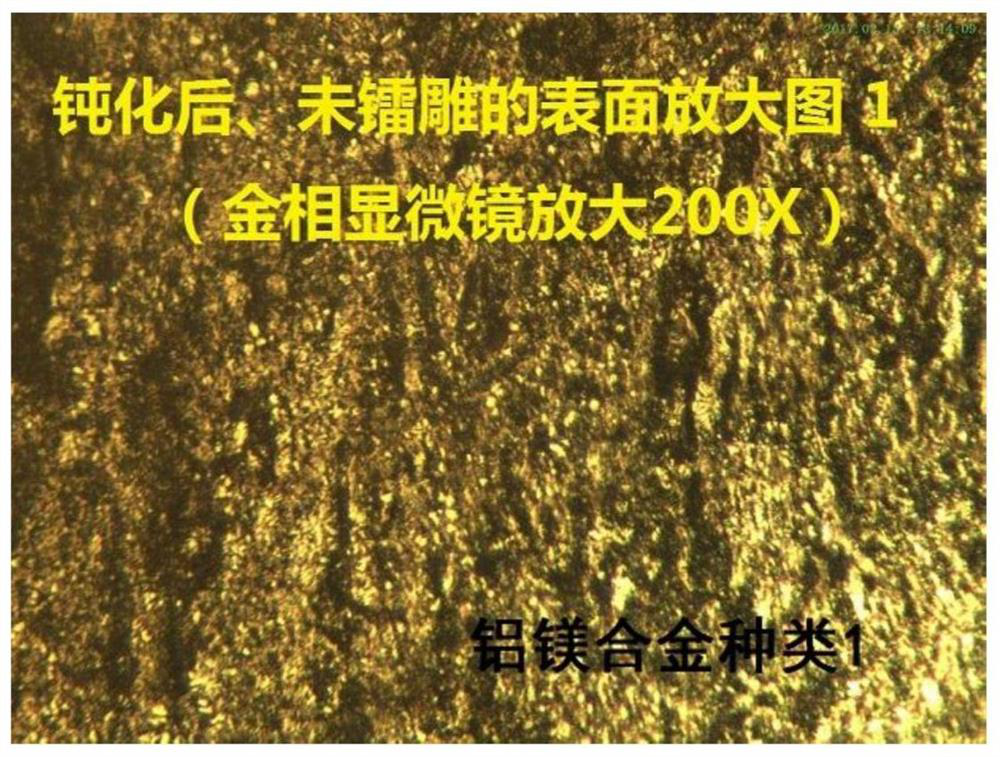

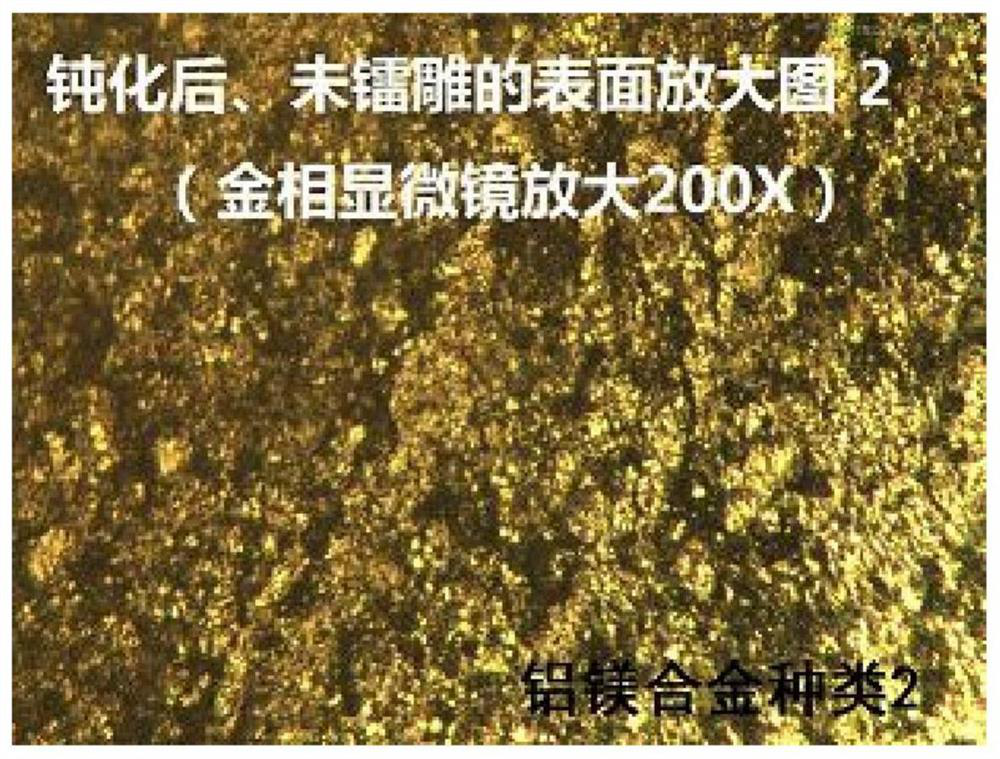

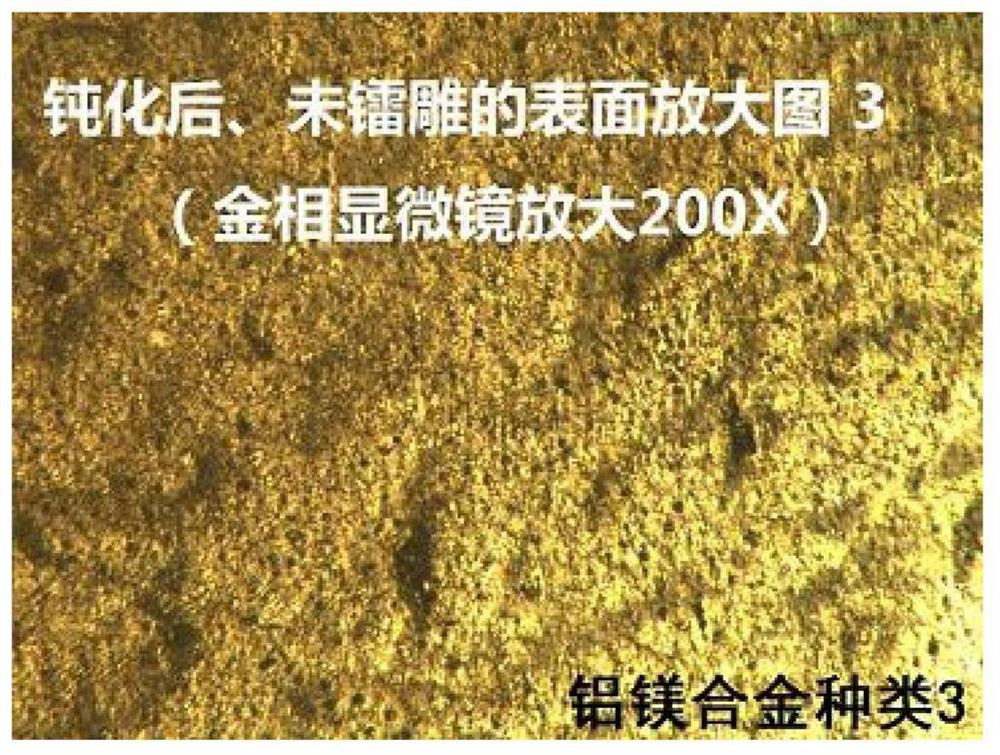

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0044] The invention uses a laser to process aluminum-magnesium alloys on the basis of a universal marking machine platform. The laser in this example uses an infrared fiber laser, and the wavelengths of ultraviolet light, green light, and CO2 are not suitable for industrial, batch, fast, and marking processing on the surface of aluminum-magnesium alloys.

[0045] The laser in this example adopts a Q-switched structure or a MOPA structure, and the method of the present invention can be used to produce qualified fish scale patterns. In addition, all 10-150W lasers on the market can use the method of the present invention to produce fish scale patterns, preferably a laser with an average power of 50-100W. If you use a 10-30W laser, you can also make fish scale patterns, but the efficiency is one level slower than 50-100W lasers; if you use a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com