Electric valve

A technology of electric valves and spools, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of large occupied space, high economic expenditure, large size, etc., to achieve easy connection and use, reduce failure rate, and ensure sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

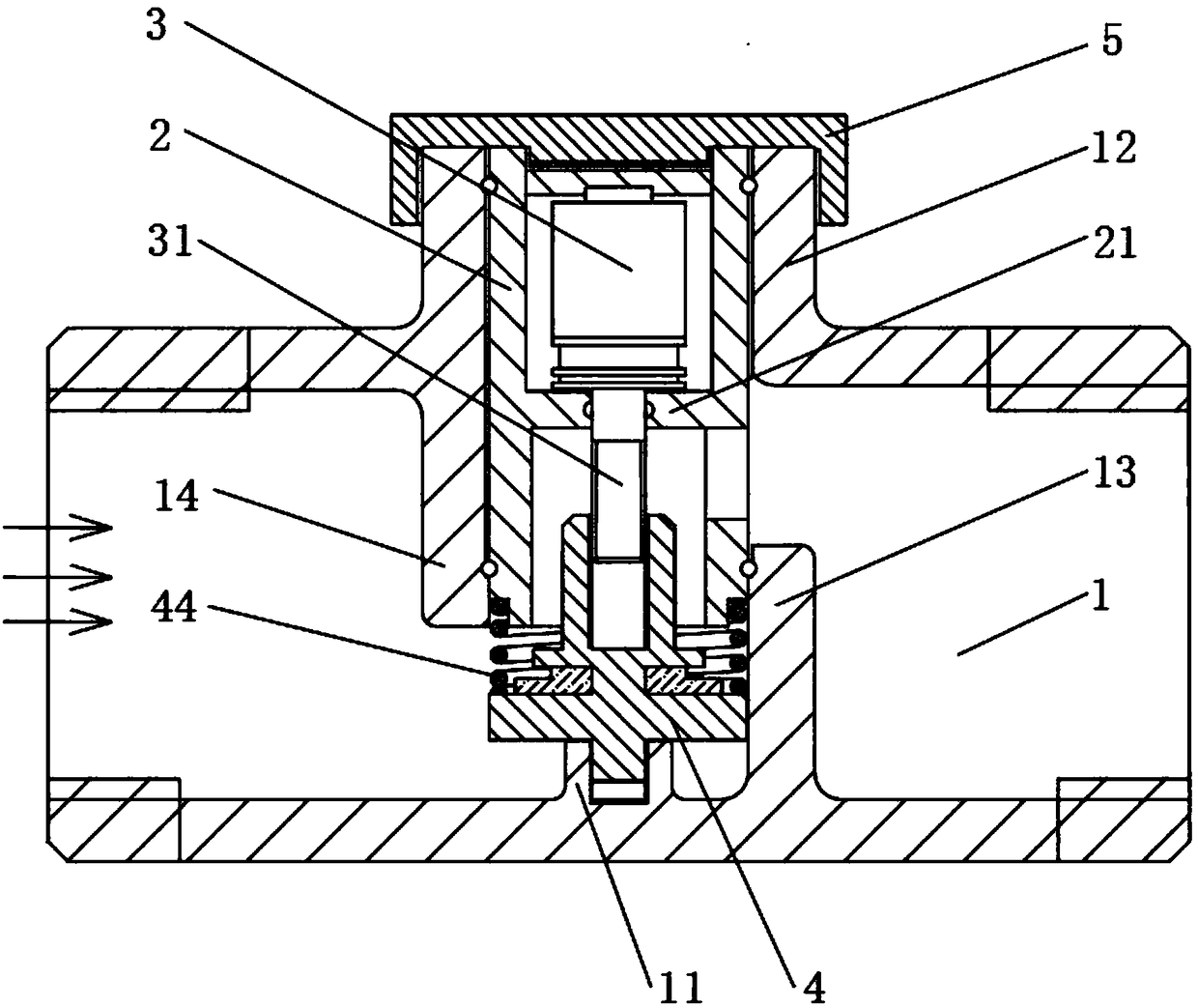

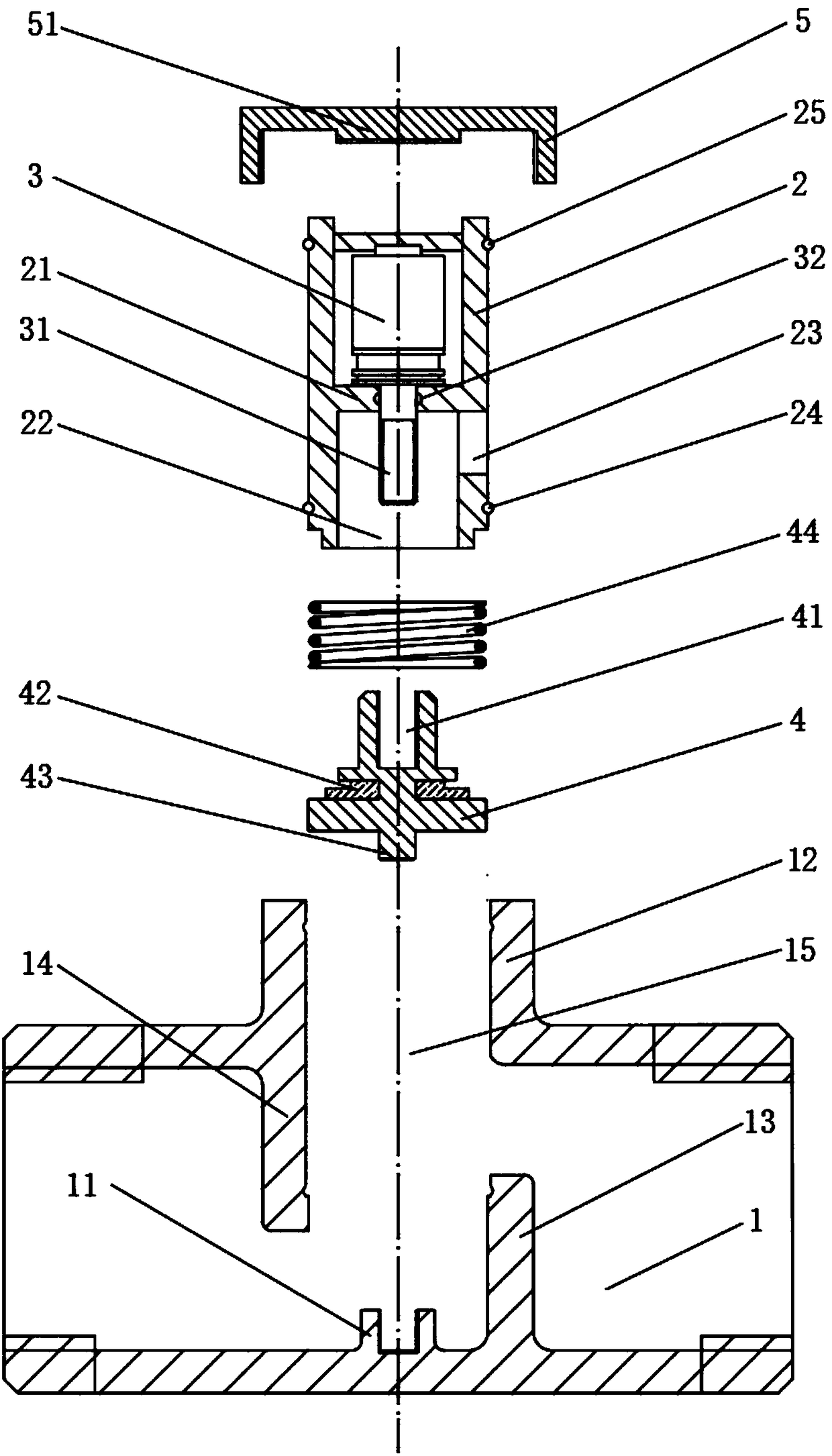

[0039] Embodiment one, according to figure 1 with figure 2 Shown:

[0040] An electric valve, characterized in that, comprising

[0041] Valve body 1, one side of the valve body 1 is provided with an extension part 12, the extension part 12 is connected with the valve body 1, and forms a valve core insertion cavity 15, the valve body 1 is opposite to the valve body The core insertion cavity 15 is connected with an upper baffle 14 and a lower baffle 13; the upper baffle 14 and the lower baffle 13 are respectively arranged on the upper left and lower right sides of the valve body 1 relative to the valve core insertion cavity 15 , the positive projection between the upper 14 and the lower 15 baffles overlaps, forming a Z-shaped flow channel with the valve body 1;

[0042] The spool 2 is located in the spool insertion cavity 15, the front end of the spool 2 is located in the middle of the Z-shaped flow channel, and a sealing ring 224 is arranged on the outside of the front end...

Embodiment 2

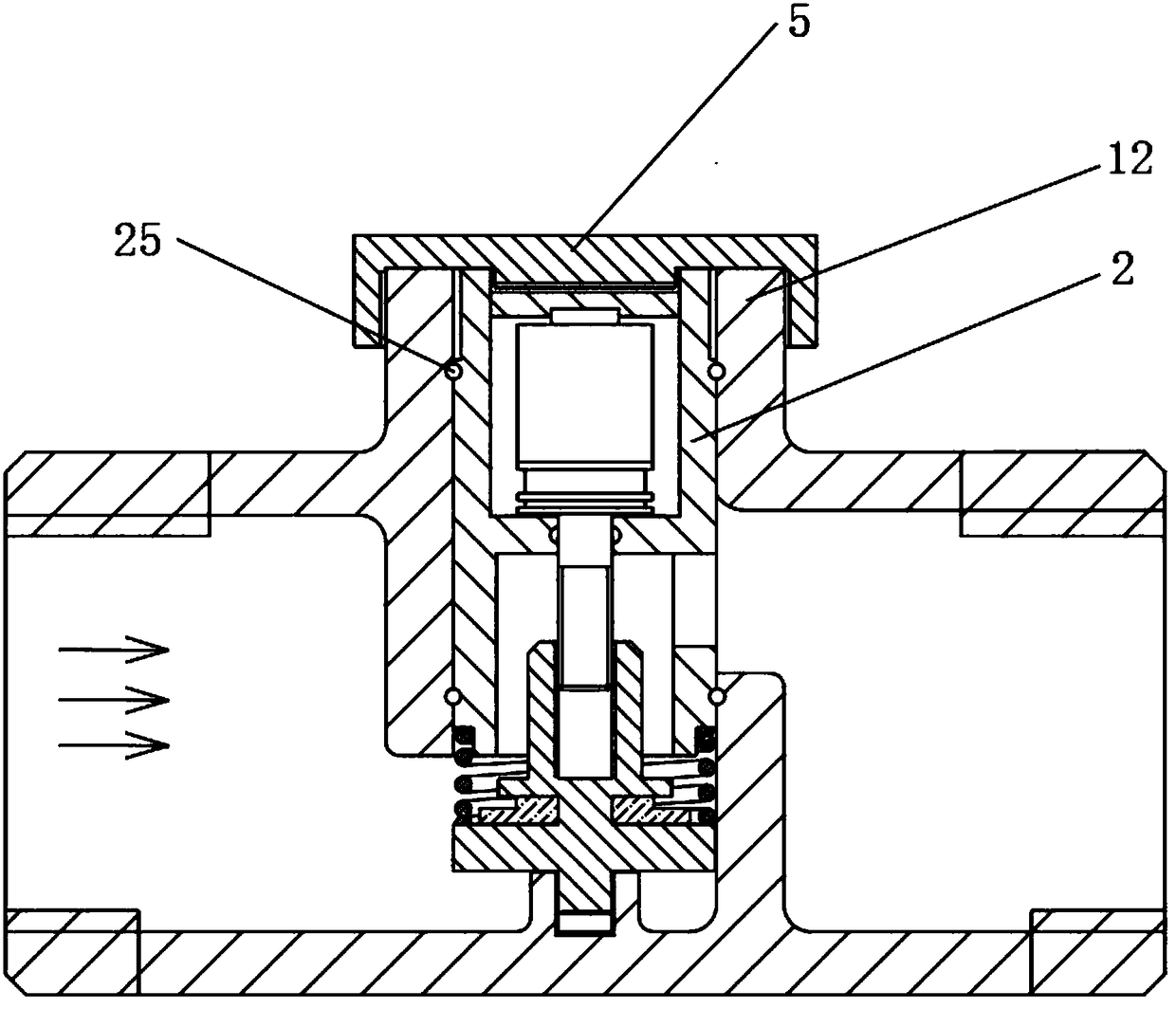

[0059] Embodiment two, according to image 3 Shown:

[0060] On the basis of the first embodiment, the rear end of the valve core 2 is screwed to the extension portion 12 of the valve body 1 . Strengthen the connection between the valve core 2 and the valve body 1 to stabilize the position of the valve core 2 and ensure the sealing.

Embodiment 3

[0062] On the basis of Embodiment 1, when the valve core 2 and the valve body 1 are designed as a whole, the seal rings 1 24 and 2 25 are canceled to reduce the number of parts and the failure rate; it is beneficial to ensure the sealing performance in the valve body 1, Prevent the tight seal caused by the assembly problem of the valve core 2 and the valve body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com