Supercritical forging electric sluice valve with double sluice plates

A technology of electric gate valves and double gates, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of large fluid resistance, short service life, high maintenance costs, etc., achieve strong wear and corrosion resistance, and ensure Long service life, advanced effect of control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

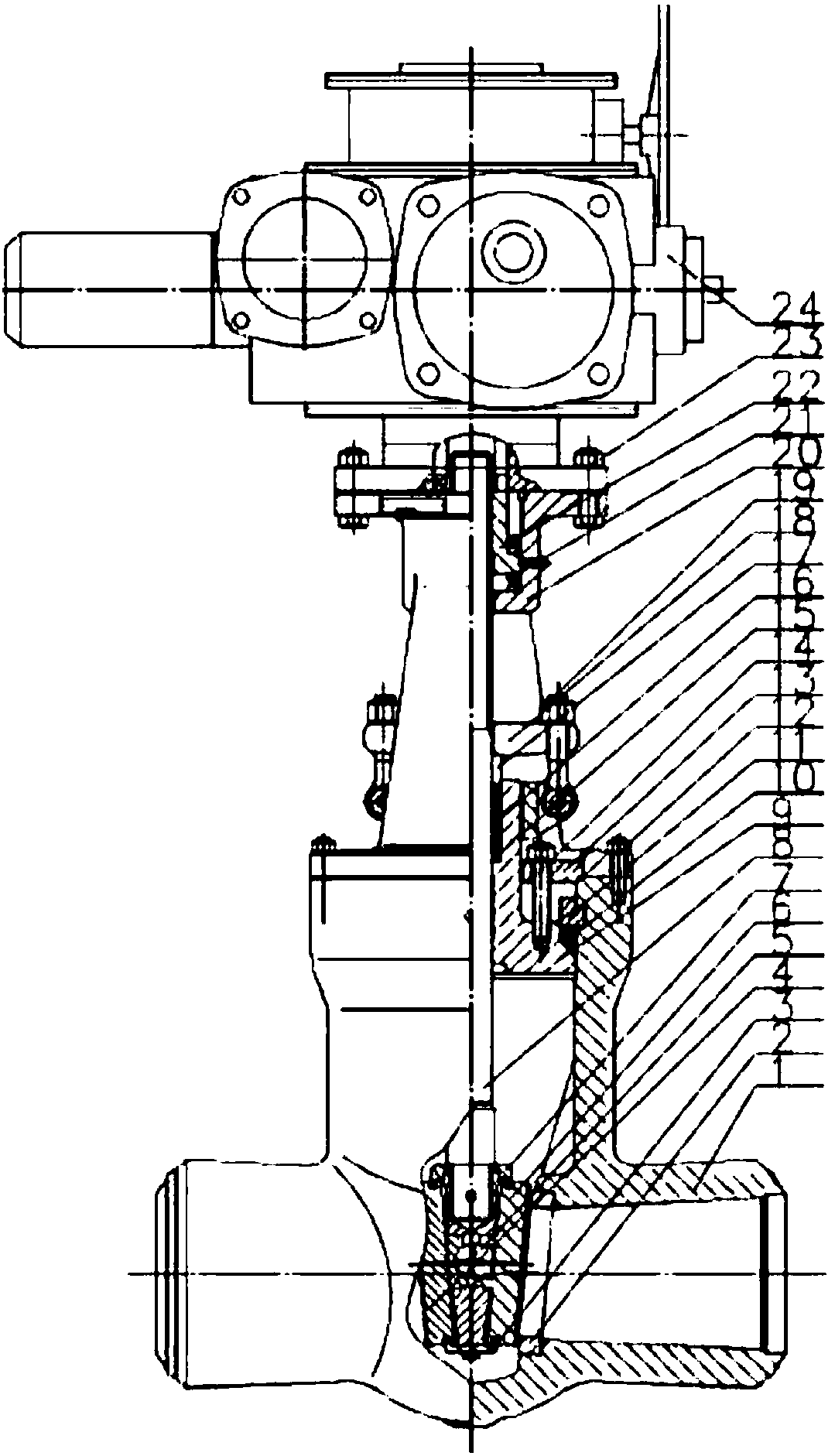

[0011] As shown in the figure, 1. Valve body, 2. Seal seat, 3. Gate bottom cover, 4. Left gate, 5. Central shaft, 6. Right gate, 7. Gate cover, 8. Valve stem , 9. Reinforced flexible graphite combined sealing ring, 10. Sealing ring, 11. Adjusting ring, 12. Bolt and nut, 13. Compression ring, 14. Bolt and nut, 15. Packing pad, 16. Combined packing, 17. Packing ring, 18, packing gland, 19, swing bolt and nut, 20, bracket, 21, thrust ball bearing, 22 valve stem nut, 23, bolt and nut, 24, electric device.

[0012] The invention includes a valve body, a sealing seat, a gate bottom cover, a left gate, a central shaft, a right gate, a gate cover, a valve stem, a reinforced flexible graphite combined seal ring, a seal ring, an adjustment ring, bolts and nuts, Compression ring, packing pad, combined packing, packing pressure ring, packing gland, swivel bolts and nuts, brackets, thrust ball bearings, valve stem nuts, bolts and nuts, electric devices; The outlet is on an axis. On the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com