Expansion joint for flue junction of coal-fired power plant

A technology for thermal power plants and joints, applied in the field of expansion joints, can solve problems such as shortening the life of expansion joints and corrosion of expansion joints, and achieve the effects of reducing corrosion, good air tightness and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

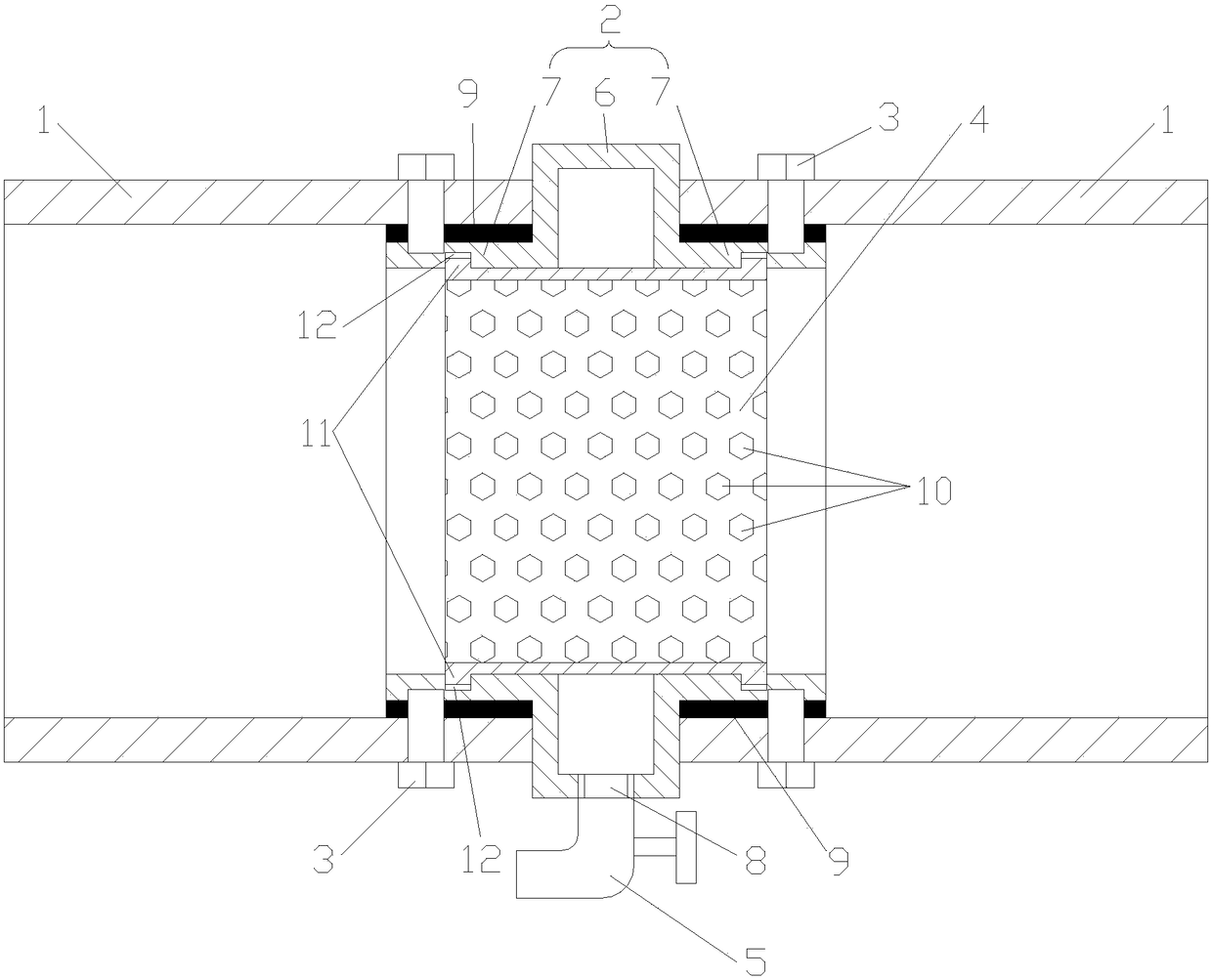

[0018] Embodiment 1 of the present invention: an expansion joint used at the joint of the flue of a thermal power plant, constituted as figure 1 As shown, it includes a body 2, a connector 3, an isolation cover 4 and a faucet 5. The body 2 includes a raised portion 6 and connecting portions 7 located at both ends of the raised portion 6. The raised portion 6 and the connecting portion 7 They are all tubular structures and integrally formed and penetrated. The wall thickness of the raised part 6 and the connecting part 7 is the same. The connecting part 7 is a tubular structure with the same shape as the flue 1, such as a square tube or a round tube. The two connecting parts 7 are respectively connected and communicated with the adjacent flue 1, and the connecting parts 7 and the flue 1 are fixed through the connecting piece 3, and the connecting piece 3 is a bolt, and after the bolt is connected, the expansion joint and the flue The connection between 1 is more stable; an isol...

Embodiment 2

[0020] Embodiment 2: A kind of expansion joint used in the joint of the flue of a thermal power plant, constituted as figure 1 As shown, it includes a body 2, a connector 3, an isolation cover 4 and a faucet 5. The body 2 includes a raised portion 6 and connecting portions 7 located at both ends of the raised portion 6. The raised portion 6 and the connecting portion 7 They are all tubular structures and integrally formed and penetrated. The wall thickness of the raised part 6 and the connecting part 7 is the same. The connecting part 7 is a tubular structure with the same shape as the flue 1, such as a square tube or a round tube. The two connecting parts 7 are respectively connected and communicated with the adjacent flue 1, and the connecting parts 7 and the flue 1 are fixed through the connecting piece 3, and the connecting piece 3 is a bolt, and after the bolt is connected, the expansion joint and the flue The connection between 1 is more stable; an isolation cover 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com