Top water-drainage device for gas exhaust chimney for industrial hazardous waste incineration

A technology for hazardous waste and exhaust chimneys, which is applied to exhaust gas devices, combustion methods, and treatment of combustion products. It can solve the problems of flue gas condensed water corroding the outer wall of the chimney, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

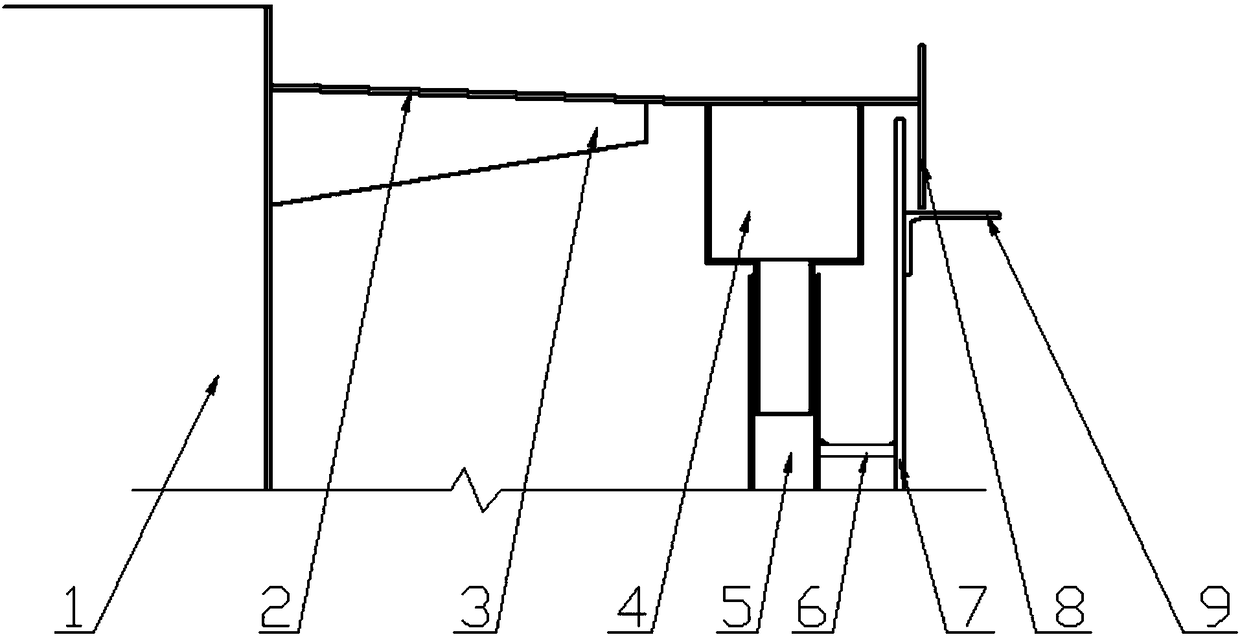

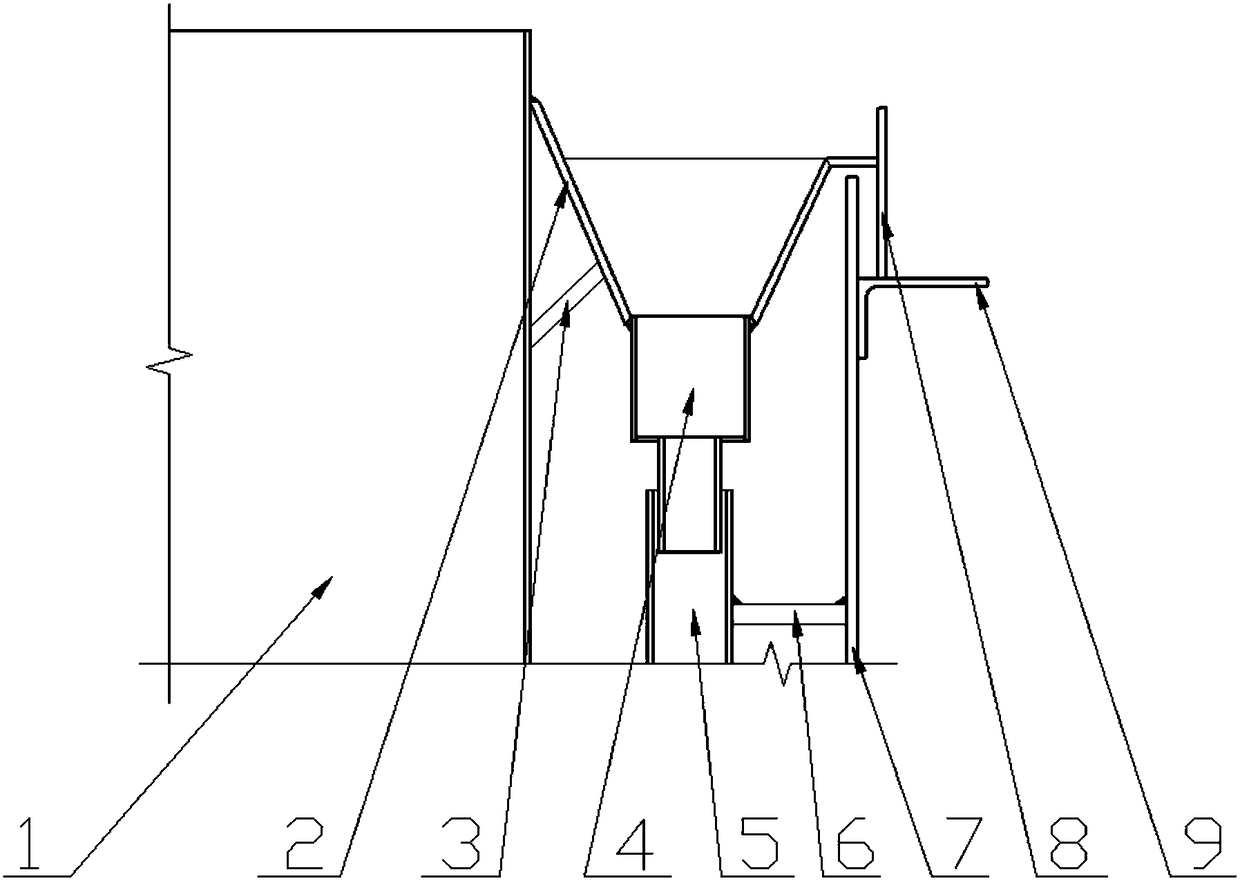

[0024] A drainage device at the top of an industrial hazardous waste incineration exhaust chimney, which adopts the method of centralized collection and separate transportation to isolate the flue gas condensed water from direct contact with the chimney cylinder, mainly including a jacket cover plate 2, a water collector 4, and a water retaining plate 8;

[0025] The present invention is arranged between the jacket of chimney inner cylinder 1 and outer cylinder 7, as figure 1 The outer wall of the chimney inner tube 1 shown is provided with a jacket cover plate 2, and the jacket cover plate 2 in this embodiment is arranged at a place 100 ± 5 mm lower than the top of the chimney inner tube 1. The surface structure of the cover plate 2 is mainly composed of any one of horizontal, inclined or concave, or mainly composed of any one of micro-U, U-shaped, V-shaped or micro-V-shaped. In this embodiment, the jacket cover The surface structure of the plate 2 is inclined, and it inclin...

Embodiment 2

[0029] The drainage device at the top of the industrial hazardous waste incineration exhaust chimney collects the condensed water of the flue gas through the condensed water collection mechanism. Under different working conditions, different structural types of jacketed covers can be used to obtain corresponding effects.

[0030] The jacketed cover plate with horizontal surface structure is suitable for the case where the condensed water produced in the flue gas discharge is relatively small, the average annual precipitation in the operating climate is small, and the jacket between the jacketed chimneys is greater than 500 mm. Condensate can be collected quickly and efficiently.

[0031] When the annual average precipitation is large and the jacket volume is less than 500 mm, the contact area between the jacket cover plate and the flue gas is small, and the condensed water cannot be collected effectively. The jacket cover plate with V-shaped surface structure is as follows: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com