Lithium battery forklift cooling system

A heat dissipation system and lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems that the cycle life can only reach 800-1000 times, the vehicle cannot work, etc., to ensure reliability and improve heat dissipation capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the drawings:

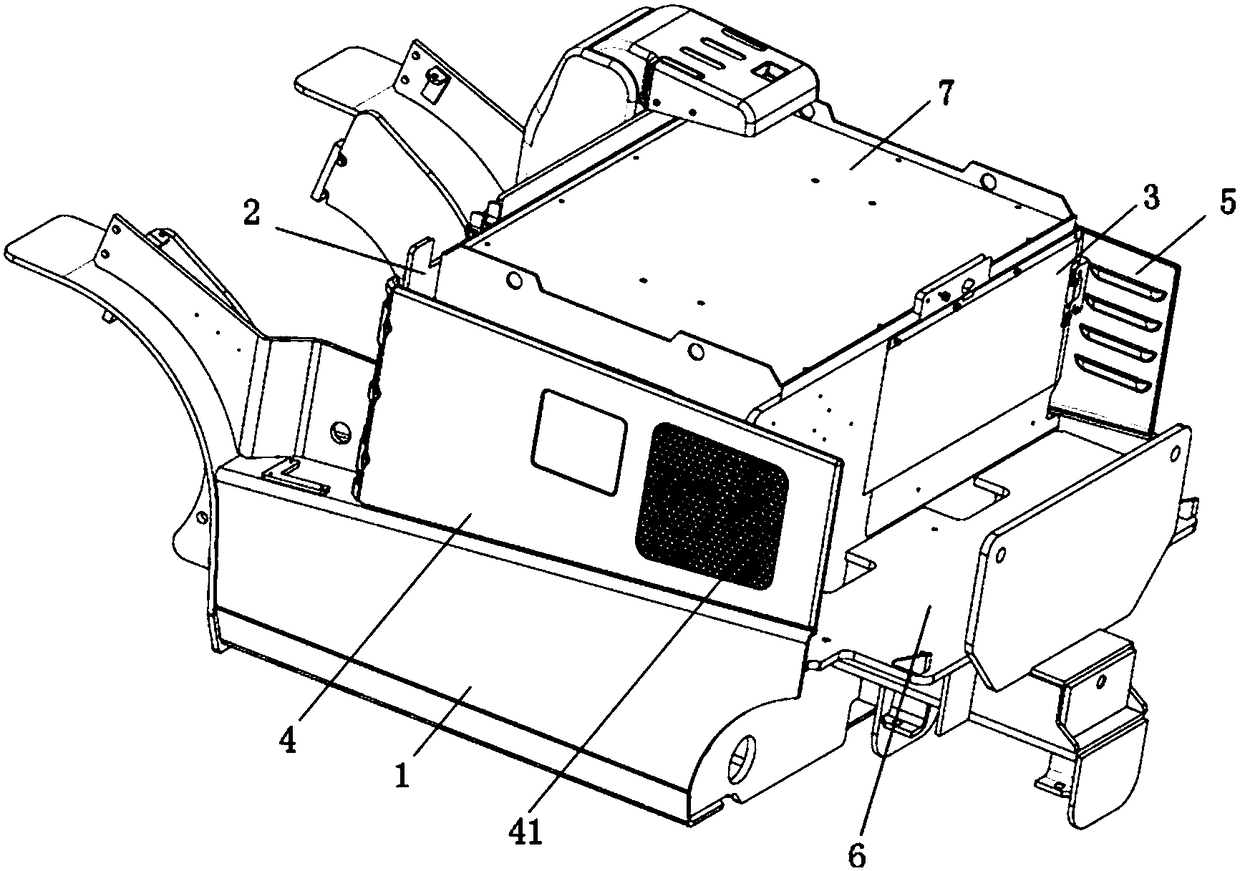

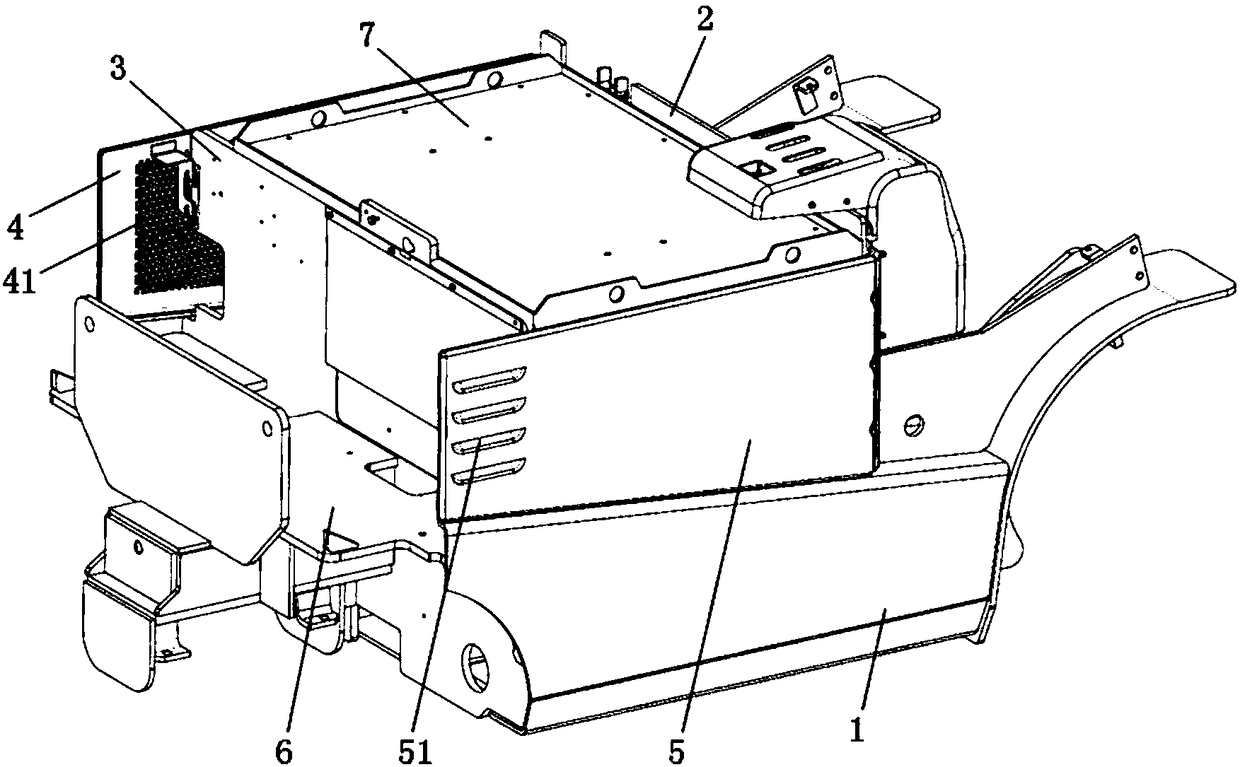

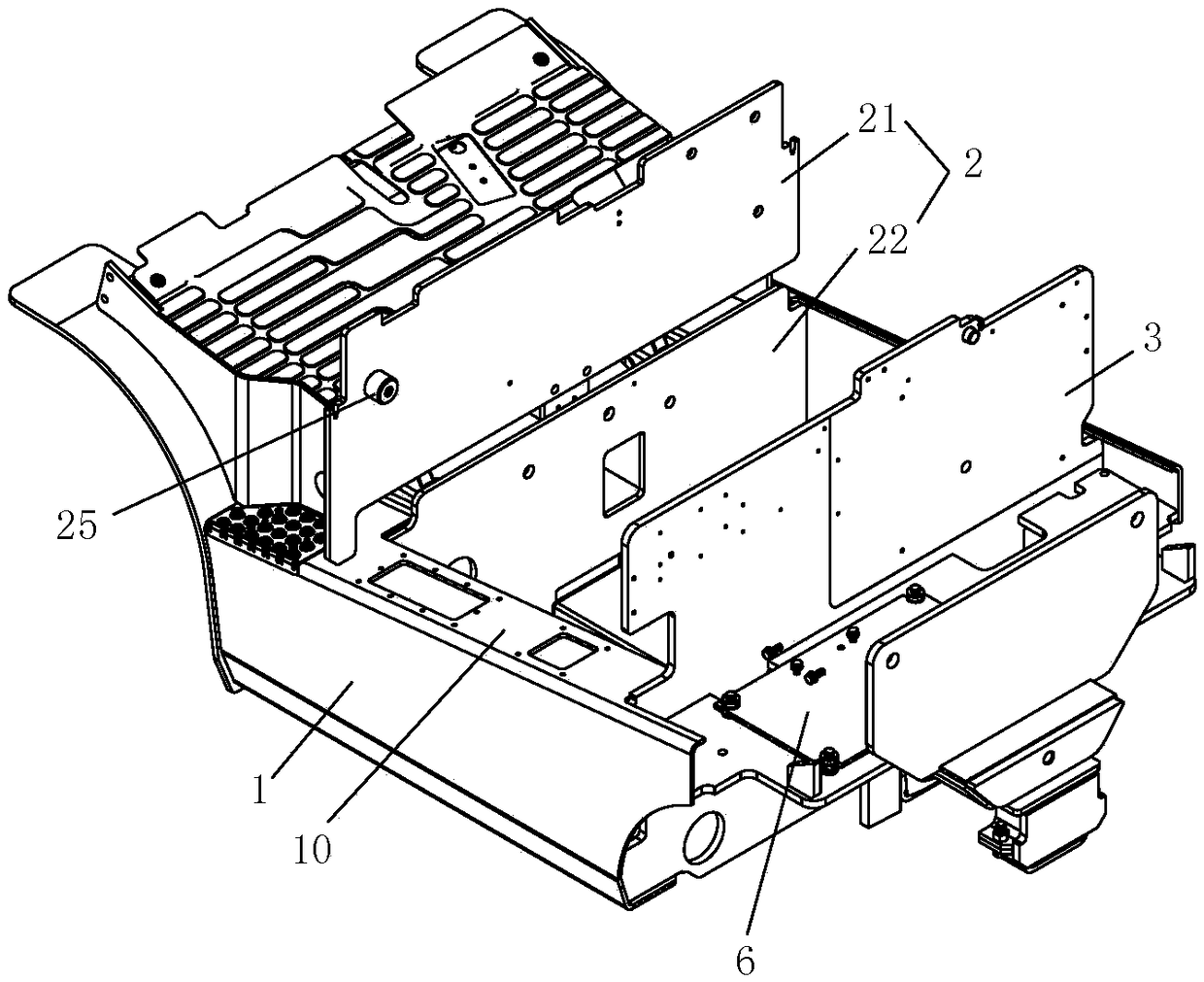

[0029] Such as figure 1 , figure 2 , image 3 , Picture 12 The heat dissipation system of a lithium battery forklift shown includes a frame body 1 and a body front panel 2, a body rear panel 3, a body left side panel 4, and a body right side panel 5 welded to the body frame 1 And the tailstock bottom plate 6, the car body front plate 2 and the car body rear plate 3 form a first space for accommodating the lithium battery assembly 7, and the car body rear plate 3 and the tailstock bottom plate 6 form a accommodating controller assembly 8 And the second space of the pump motor 9. Specifically, the controller assembly 8 is installed on the rear plate 3 of the car body, and the pump motor 9 is installed on the tailstock bottom plate 6; the left side of the frame body 1 is welded with a hydraulic oil tank 10, and the hydraulic oil tank 10 is located between the front panel 2 of the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com