Wheel axle type particle accelerator energy reducing device and energy reducing method in vacuum

A particle accelerator and energy reduction technology, which is applied in accelerators, electrical components, etc., can solve the problems of high positioning accuracy, insufficient compactness of the energy reducer, and large increase in emissivity, so as to avoid excessive growth, compact structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

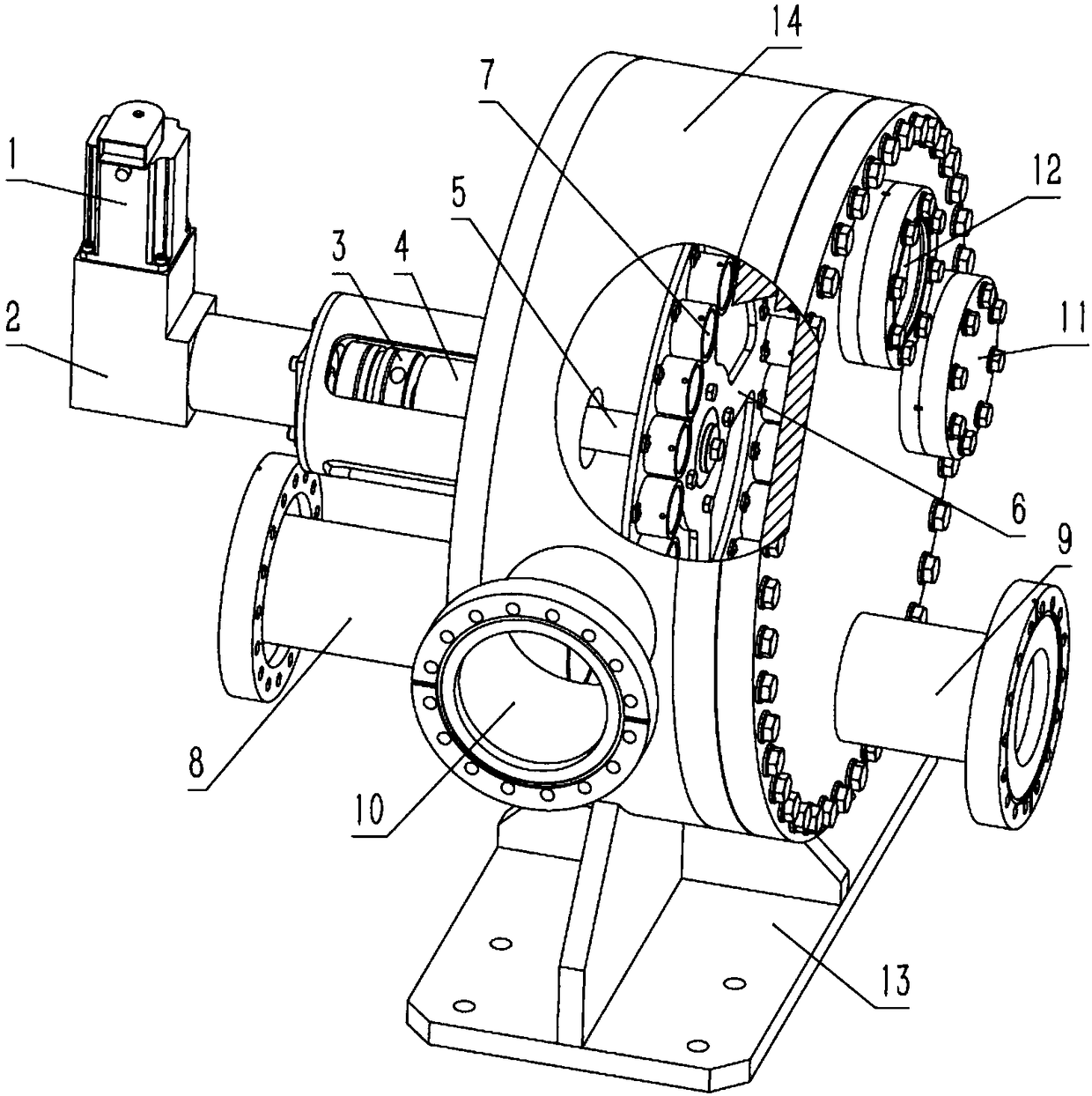

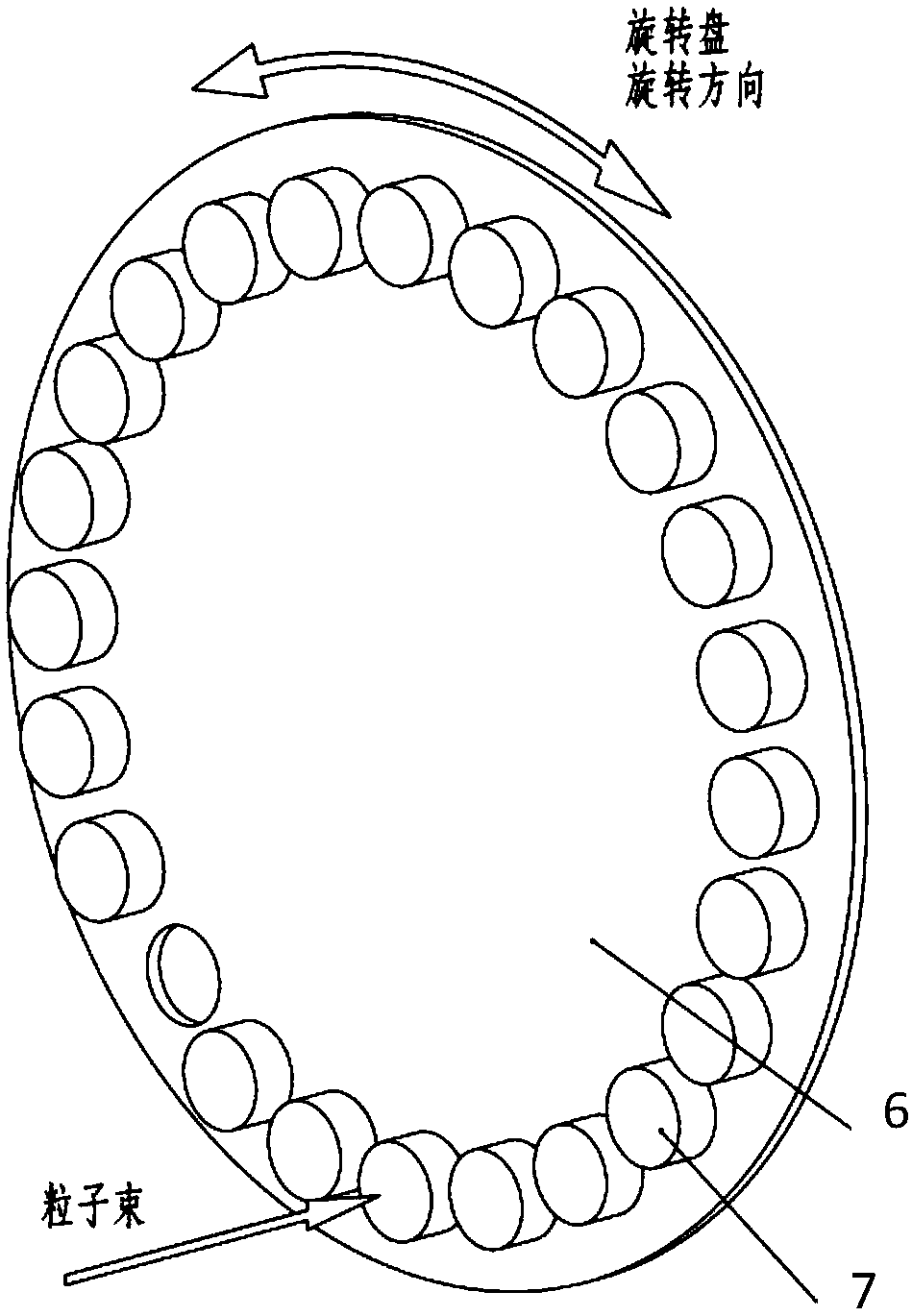

[0037] From figure 1 It can be seen that the energy reducing device in this embodiment mainly includes a rotary drive mechanism, a vacuum chamber 14 and an energy reducing turntable located inside the vacuum chamber 14;

[0038] The rotary drive mechanism includes a servo motor 1, a reducer 2 and a magnetic fluid seal transmission device 4;

[0039] The input shaft of the reducer 2 is connected with the output shaft of the servo motor 1, the output shaft of the reducer 2 is connected with the central shaft 5 of the magnetic fluid seal transmission 4 through the coupling 3, and the central shaft 5 of the magnetic fluid seal transmission 4 passes through The vacuum cavity 14 is connected with the energy-reducing turntable; the magnetic fluid sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com