Spiral ore washing machine without frame type permanent magnet synchronous motor direct drive

A technology of permanent magnet synchronous motor and spiral washing machine, which is applied to synchronous motors with static armatures and rotating magnets, synchronous machine parts, magnetic circuits, etc., can solve the problems of unsatisfactory effect and slow production efficiency, etc. To achieve the effect of simplifying the driving mode and structure, reducing the production cost, and improving the operation reliability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

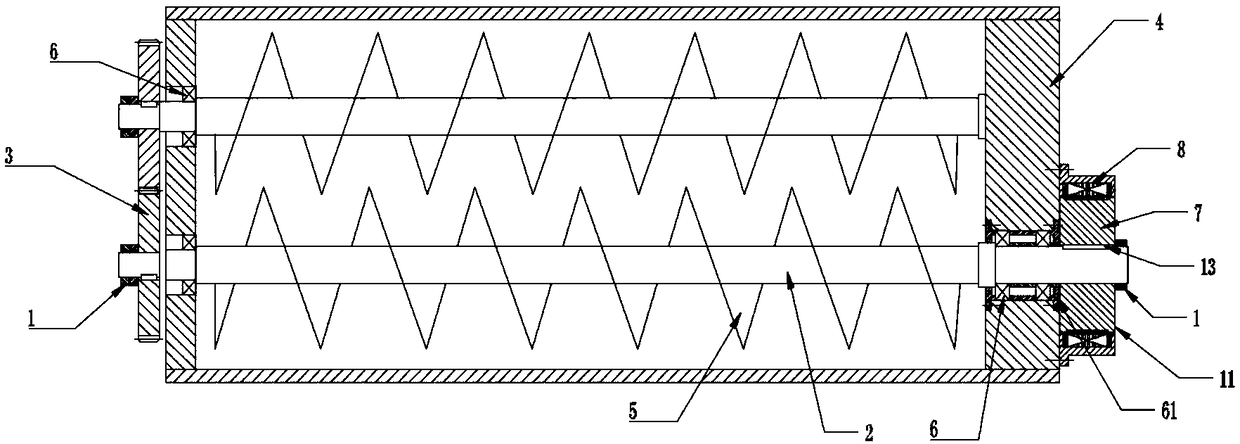

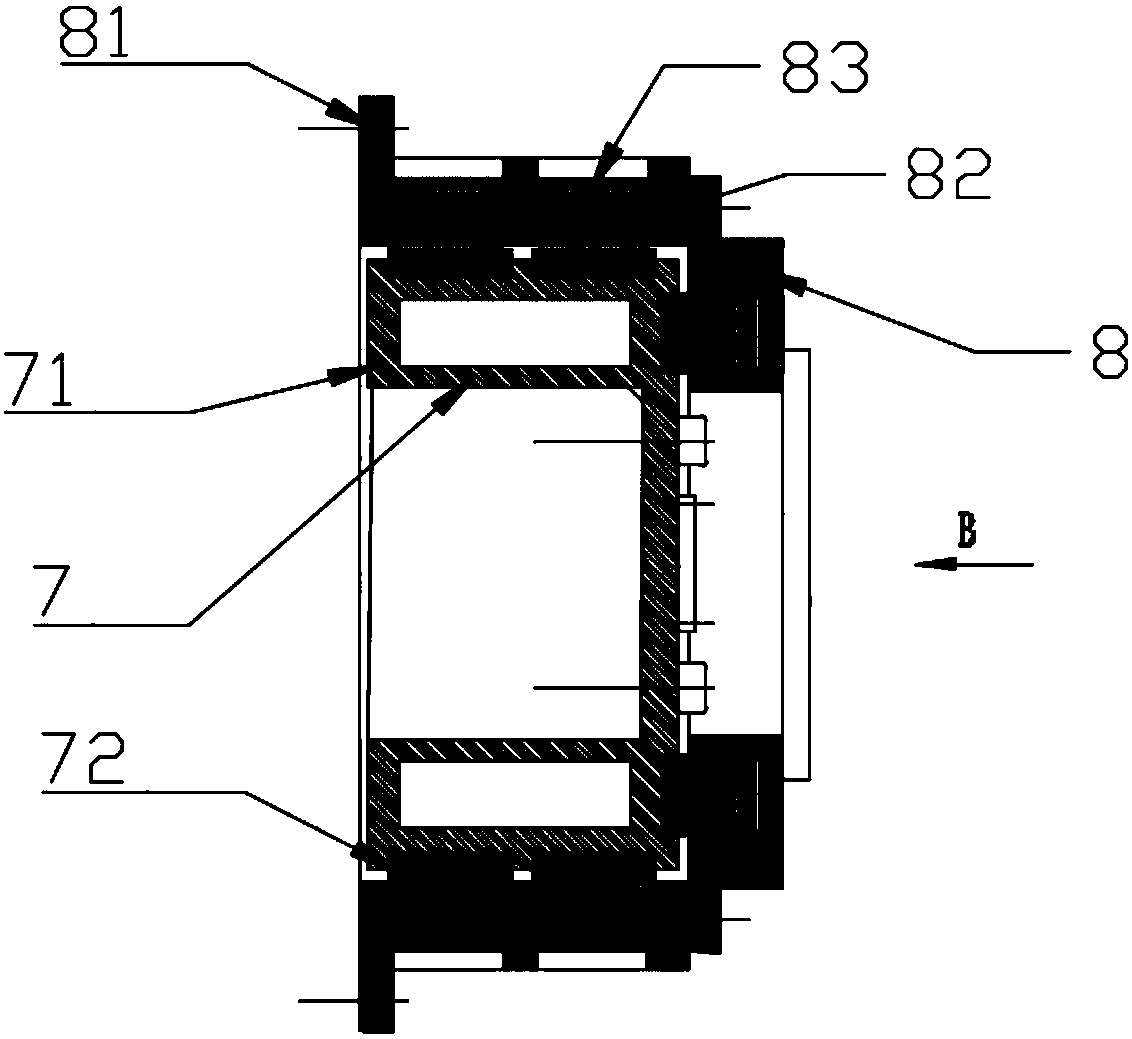

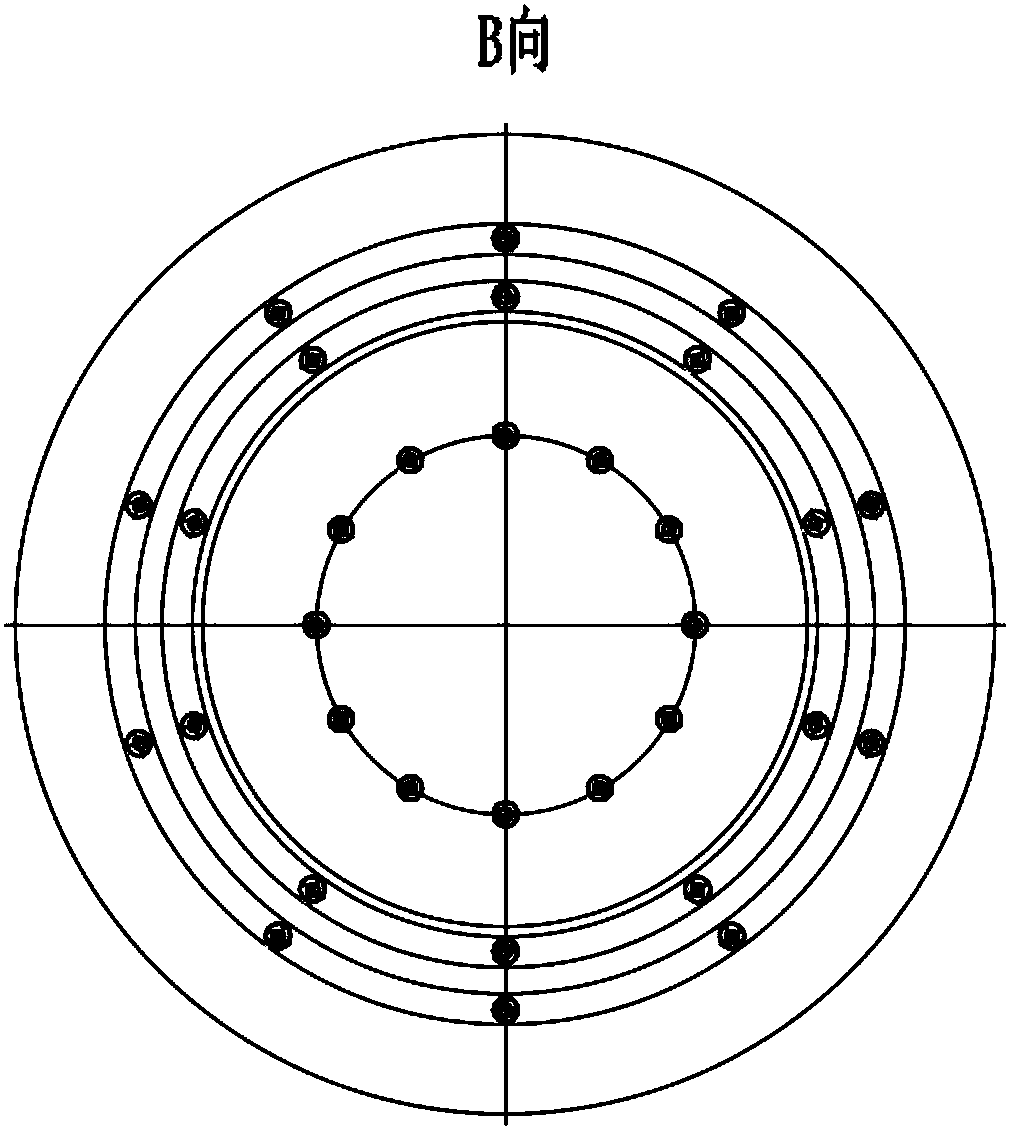

[0033] like Figure 1~3 As shown, this embodiment provides a frameless permanent magnet synchronous motor direct-driven spiral washing machine, the spiral washing machine includes a rotating shaft 2 with a spiral blade 5, and the rotating shaft 2 is arranged on a frame 4 The number of the rotating shaft 2 is at least two, preferably two in this embodiment; the two rotating shafts 2 are arranged in parallel; the upper end of one of the rotating shafts 2 is fixedly connected with the drive motor, and the lower end Connected to the other rotating shaft 2 through a transmission gear assembly 3; the drive motor is a frameless permanent magnet synchronous motor 11, including a stator assembly 8 and a rotor assembly 7; the stator assembly 8 is fixed on the frame 4 Above, a rotating magnetic field is provided for the rotor assembly 7, and the rotor assembly 7 is connected to the rotating shaft 2; the stator assembly 8 includes a stator base 81, a stator core 82 and a stator winding 83...

Embodiment 2

[0038] like Figure 4~5 As shown, the preferred embodiment of the present invention is to provide a frameless combined permanent magnet synchronous motor direct-driven spiral washing machine, the structure and working principle of this embodiment are similar to embodiment 1, and the The difference is that the rotor assembly in this embodiment also includes pressure plates 73 distributed in the axial and / or circumferential directions of the rotor base 71, and the magnetic steel base plate 72 is arranged on the pressure plate 73 and the rotor base. between the seats 71; the inner cavity of the pressing plate 73 is provided with the magnetic steel substrate 72, the edge of the pressing plate 73 is provided with a flange 74, and the flange 74 and the rotor base 71 are equipped with evenly distributed The positioning hole is used for fixing the magnetic steel substrate 72 embedded in the pressing plate 73 on the rotor base 71 . The panel of the pressure plate 73 is provided with s...

Embodiment 3

[0040] like Figure 6 As shown, the preferred embodiment of the present invention is to provide a frameless permanent magnet synchronous motor direct-driven spiral washing machine, the structure and working principle of this embodiment are similar to embodiment 1 or 2, but with embodiment 1 The difference between or 2 is that the stator assembly 8 in this embodiment is also provided with a cooling device; the cooling device includes a cooling water pipe 9 annularly arranged on the stator core, and / or the stator base The cooling air channel 10 on the top, the direction of the cooling air channel 10 is perpendicular to the rotation plane of the rotor assembly 7 . The stator assembly 8 generates a rotating magnetic field and drives the rotation of the roll, which will generate a large amount of heat and affect the normal operation of the equipment. The circulating water in the cooling water pipe 9 will take out the heat generated by the equipment in time. Secondly, The cooling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com