Dry/wet wipable whiteboard pen ink and preparation method thereof

A pen-ink and whiteboard technology, applied in ink, household utensils, applications, etc., can solve the problems of affecting secondary writing, ink is not easy to dry, difficult to erase, etc., and achieves the effect of convenient dry erasing, easy wiping, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

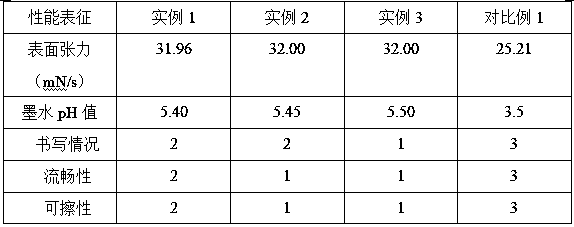

Examples

Embodiment Construction

[0021] Take 10~12g carbon black into 100~120mL deionized water, stir and mix at 300~400r / min for 20~30min, and adjust the pH to 13~14 with a mass fraction of 20% sodium hydroxide solution, then transfer it to the rotary evaporator Evaporate to dryness to obtain pretreated carbon black. Take 10~12g of pretreated carbon black and put it into the autoclave, continue to inject ozone until the pressure in the autoclave is 10~12MPa, keep the pressure and react for 3~5h, then turn on the high pressure Reactor valve, quickly release the pressure to normal pressure and then take it out to obtain the reactant. Soak the reactant in 300-360mL deionized water for 20-30 minutes, and adjust the pH to 3 to 4 with 10% hydrochloric acid, and then transfer to centrifugation. Centrifugal separation in the machine at 5000~6000r / min, collect the precipitate, wash the precipitate with deionized water 2~3 times, place it in a vacuum drying oven, and dry it to constant weight at 105~110℃ to obtain oxidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap