A kind of cu-ag-fe-c alloy and preparation method thereof

A cu-ag-fe-c and alloy technology, applied in the field of Cu-Ag-Fe-C alloy and its preparation, can solve the problems of slow diffusion speed and achieve the effect of improving electrical conductivity and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The alloy prepared in this embodiment is Cu-2.0wt%Ag-15wt% (Fe-C) alloy, that is: in this alloy, the content of Fe-C is 15wt%, the content of Cu is 83wt%, and the content of Ag is 2wt%, wherein, the mass percentage of C in the Fe-C alloy powder is 1wt%. The specific preparation method is as follows:

[0031] Melt 99.9wt% electrolytic high-purity Cu and elemental Ag in a vacuum intermediate frequency induction furnace. The melting temperature is controlled at 1100±5°C and the vacuum degree is 10Pa. -120nm Fe-C alloy powder is added to the copper-silver alloy liquid, and mechanically stirred at a stirring speed of 300rpm under the condition of 1100±5°C for 3 minutes, so that the solid Fe-C powder alloy is evenly distributed in the copper-silver alloy liquid, and then It is poured into a water-cooled copper mold for rapid cooling at a cooling rate of 100°C / s, and the obtained Cu-2.0wt%Ag-15wt% (Fe-C) alloy is obtained after pouring.

[0032] The performance test of the a...

Embodiment 2-4

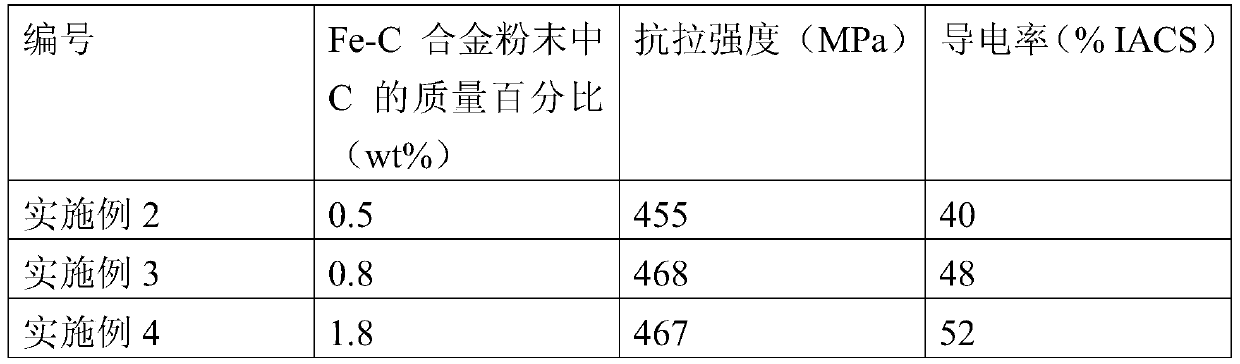

[0034] Examples 2-4 are the same as Example 1 except that the mass percentage of C in the Fe-C alloy powder is different from Example 1. See Table 1 for the mass percentage of C in the Fe—C alloy powders of Examples 2-4 and the properties of the obtained alloys.

[0035] Process parameter and performance result of table 1 embodiment 2-4

[0036]

Embodiment 5-6 and comparative example 1

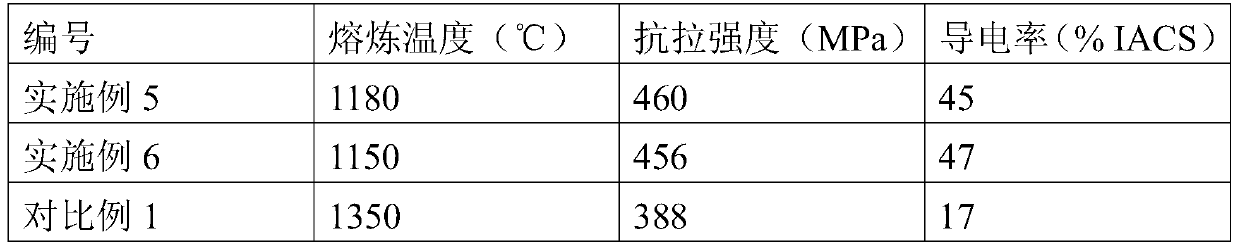

[0038] Embodiment 5-6 and comparative example 1 are different from embodiment 1 except that melting temperature and temperature during stirring (melting temperature is equal to temperature during stirring) are different from embodiment 1, and other process parameters are the same as embodiment 1. See Table 2 for the melting temperatures of Examples 5-6 and Comparative Example 1 and the properties of the obtained alloys.

[0039] Table 2 embodiment 5-6 and the process parameter and performance result of comparative example 1

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com