Internet-of-things-based drainage valve optimization method

An optimization method and drainage valve technology, applied in the direction of neural learning methods, biological neural network models, network topology, etc., can solve problems such as difficulty in finding drain valve faults, lack of monitoring devices for drain valves, time-consuming and labor-intensive inspection of valves, etc., to achieve Optimize the opening time, protect the environment, and reduce the effect of gas consumption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

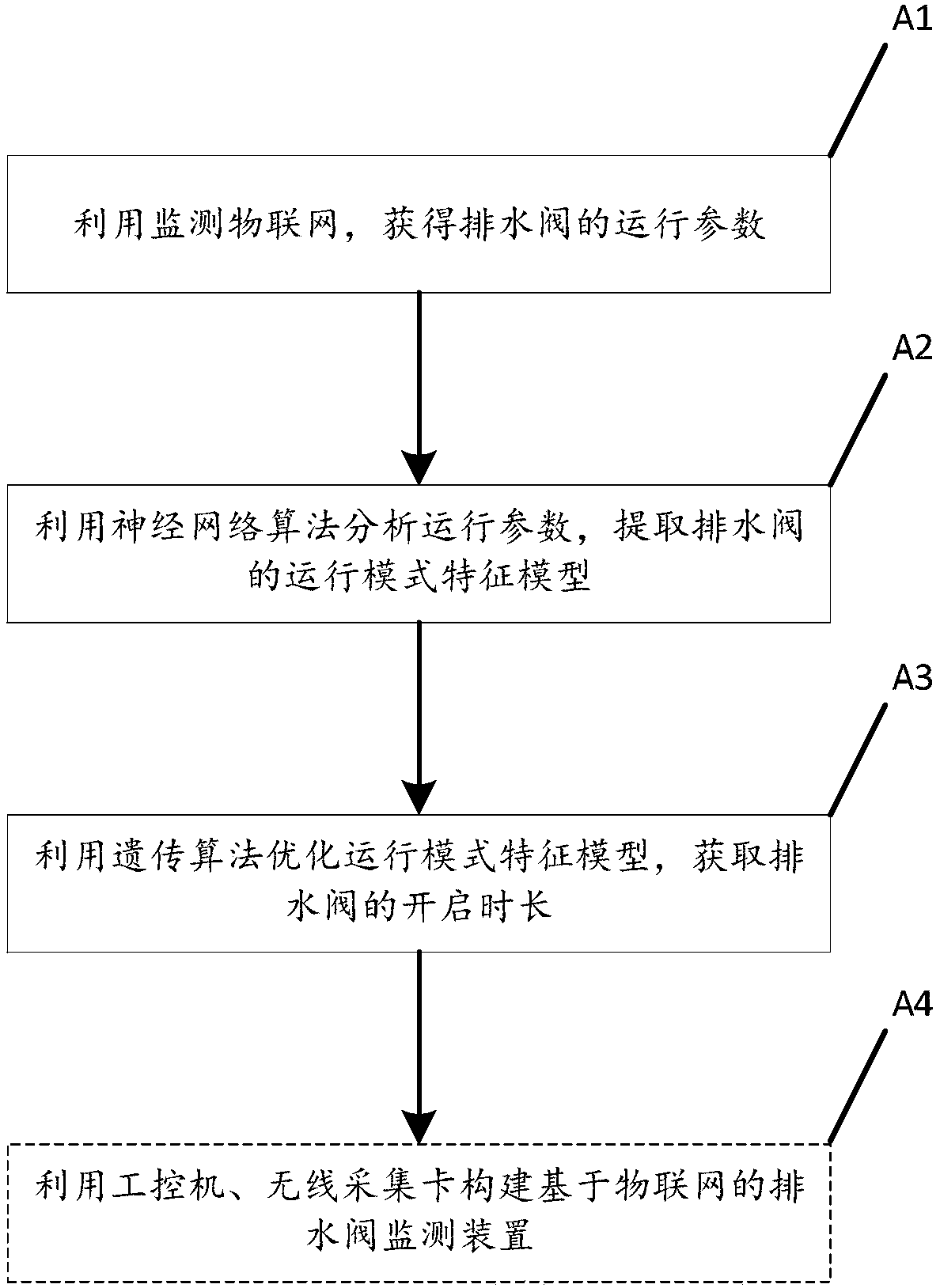

[0039] figure 1 Schematically provides a flow chart of an Internet of Things-based drain valve optimization method according to an embodiment of the present invention, as figure 1 As shown, the drain valve optimization method based on the Internet of Things comprises the following steps:

[0040] (A1) Use the wireless Zigbee Internet of Things to obtain the operating parameters of the drain valve, such as liquid level signal, valve opening time, ambient temperature, and ambient humidity;

[0041] (A2) Utilize the neural network algorithm to analyze the operating parameters, and extract the operating mode characteristic model of the drain valve; specifically:

[0042] The neural network training modeling process includes the following steps:

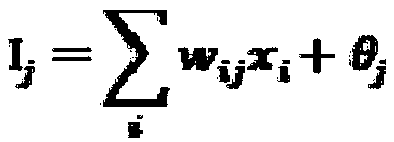

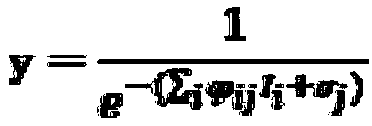

[0043] (B1) The relationship from the input layer to the hidden layer; the input layer includes: valve opening time, ambient temperature, and ambient humidity; the output layer includes: the liquid level of the drain valve; for the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com