Lactic acid bacteria formula and fermentation technique

A lactic acid bacteria and formula technology, applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of short shelf life, effect of storage time, inconvenient drinking of solid lactic acid bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

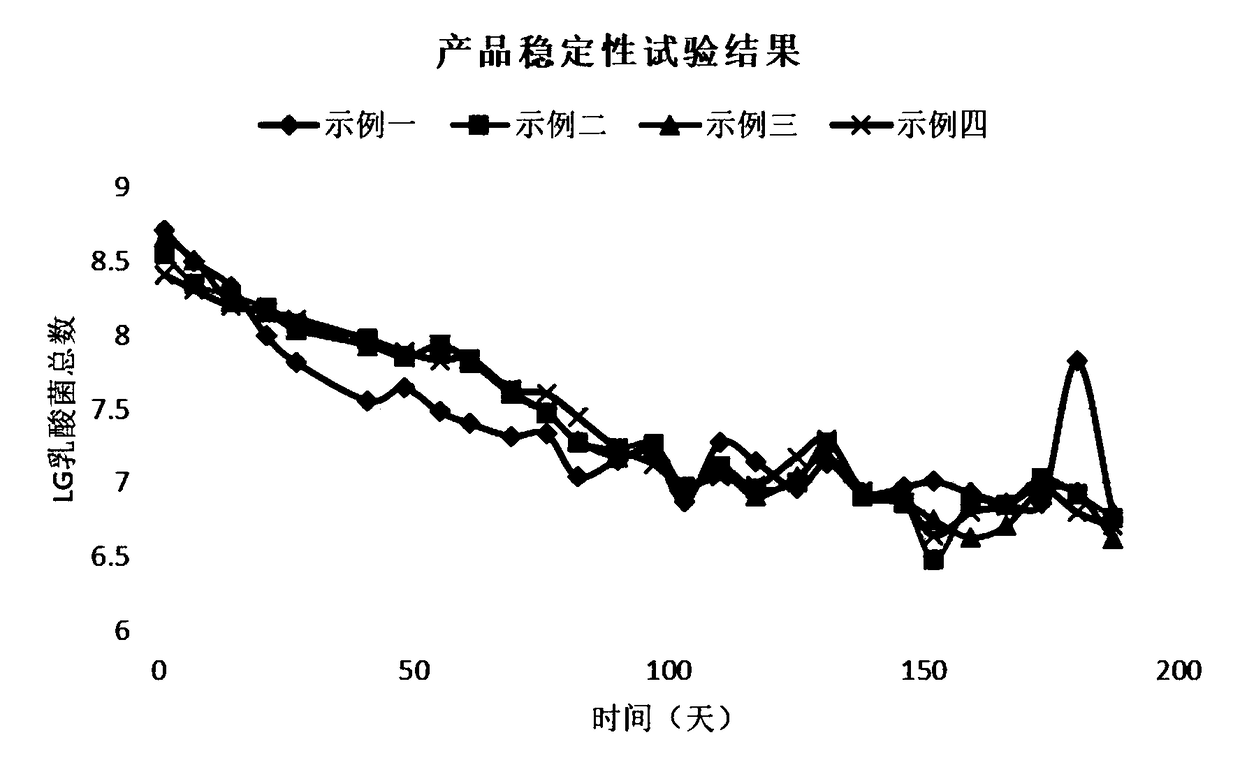

Image

Examples

Embodiment 1

[0024] (1) Fermentation substrate treatment: crush 70kg of barley, add 250L of hot water at 40°C, stir well, add 10ml of glucoamylase, keep warm for 30min, then quickly heat up to 80°C within 20min, keep warm for 90min, and then pass 100 Take 200L supernatant after filtering.

[0025] (2) Preparation of fermentation broth: add 40kg isomalt, 2.5kg xanthan gum, 1kg pectin, 5kg sodium citrate, 100g sucralose, 100g potassium sorbate into 700L water, keep the temperature at 122°C, After autoclaving for 25 minutes, the initial fermentation liquid was obtained; then 100 g of vitamin C was added to 10 L of purified water, filtered through a pore size of 0.22 μm, and then added to the above initial fermentation liquid when the temperature was lowered to 40 ° C to obtain a fermentation liquid.

[0026] (3) Inoculation: After adding the fermented substrate treated in step (1) to the fermented liquid obtained in step (2), when the temperature is lowered to 36°C, inoculate 1000 g of Lactob...

Embodiment 2

[0029] (1) Fermentation substrate treatment: crush 35kg of barley and 20kg of rice, add 250L of hot water at 40°C, stir evenly, add 10ml of glucoamylase, keep warm for 90min, then quickly raise the temperature to 79°C within 25min, and keep warm for 80min , and then take 200L of the supernatant after filtering through 100 meshes to obtain a processed fermentation substrate.

[0030] (2) Preparation of fermentation broth: add 10kg isomalt, 2.5kg sodium carboxymethylcellulose, 1kg gellan gum, 3kg sodium citrate, 2kg sodium malate, 200g sucralose, and 100g potassium sorbate 700L of water, 121°C, 20min autoclaving to obtain the initial fermentation liquid; then add 100g of vitamin C to 9L and filter through a pore size of 0.22um, and then add it to the above-mentioned initial fermentation liquid when the temperature is lowered to 38°C to obtain the fermentation liquid.

[0031] (3) Inoculation: After adding the fermented substrate treated in step (1) to the fermented liquid obtain...

Embodiment 3

[0034] (1) Fermentation substrate treatment: crush 5kg of barley flour, 25kg of corn, and 25kg of Chinese yam, add 250L of hot water at 40°C, stir evenly, add 20ml of glucoamylase, keep warm for 70min, and then rapidly heat up to 75°C in 10min , keep warm for 90min, then take 200L of supernatant after filtering through 100 mesh, and obtain the processed fermentation substrate.

[0035] (2) Preparation of fermentation broth: add 15kg isomalt, 200g aspartame, 2.5kg sodium carboxymethylcellulose, 1kg gellan gum, 2kg sodium malate, 1kg sodium lactate, 100g potassium sorbate to 700L In water, keep the temperature at 123°C, autoclave for 30 minutes to obtain the initial fermentation liquid; then add 100g of vitamin C to 10 purified water and filter through 0.22um pore size, and when the antioxidant aqueous solution cools down to 37°C, add the above initial fermentation liquid , to obtain a fermentation broth.

[0036] (3) Inoculation: After adding the fermented substrate treated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com