Hydraulic retarder and auxiliary deceleration system for medium and small vehicles

A technology of hydraulic retarder and deceleration system, applied in the field of automobile brake system, can solve the problems of inability to install hydraulic retarder and large volume, and achieve the effects of light weight, small equipment volume and large damping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

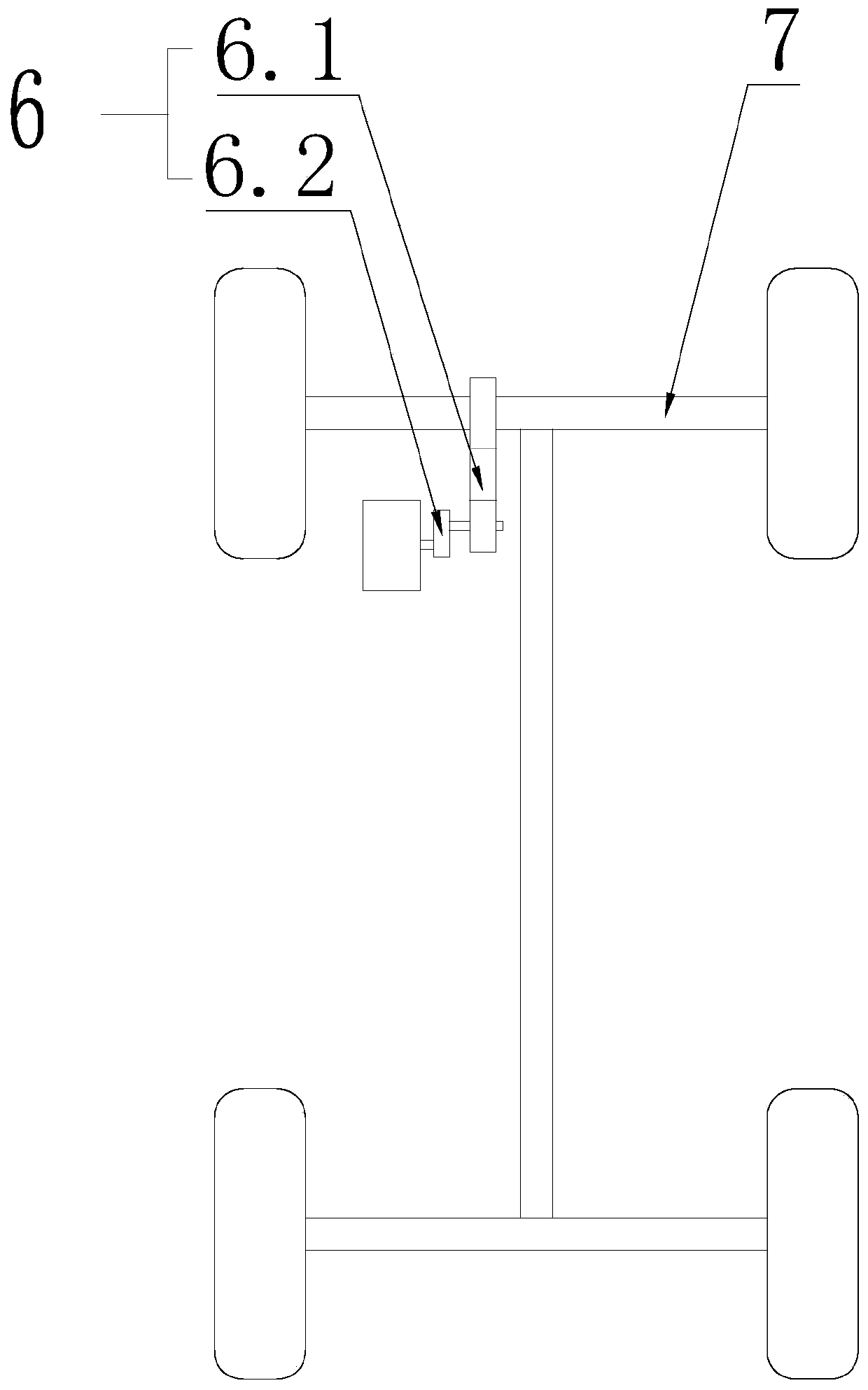

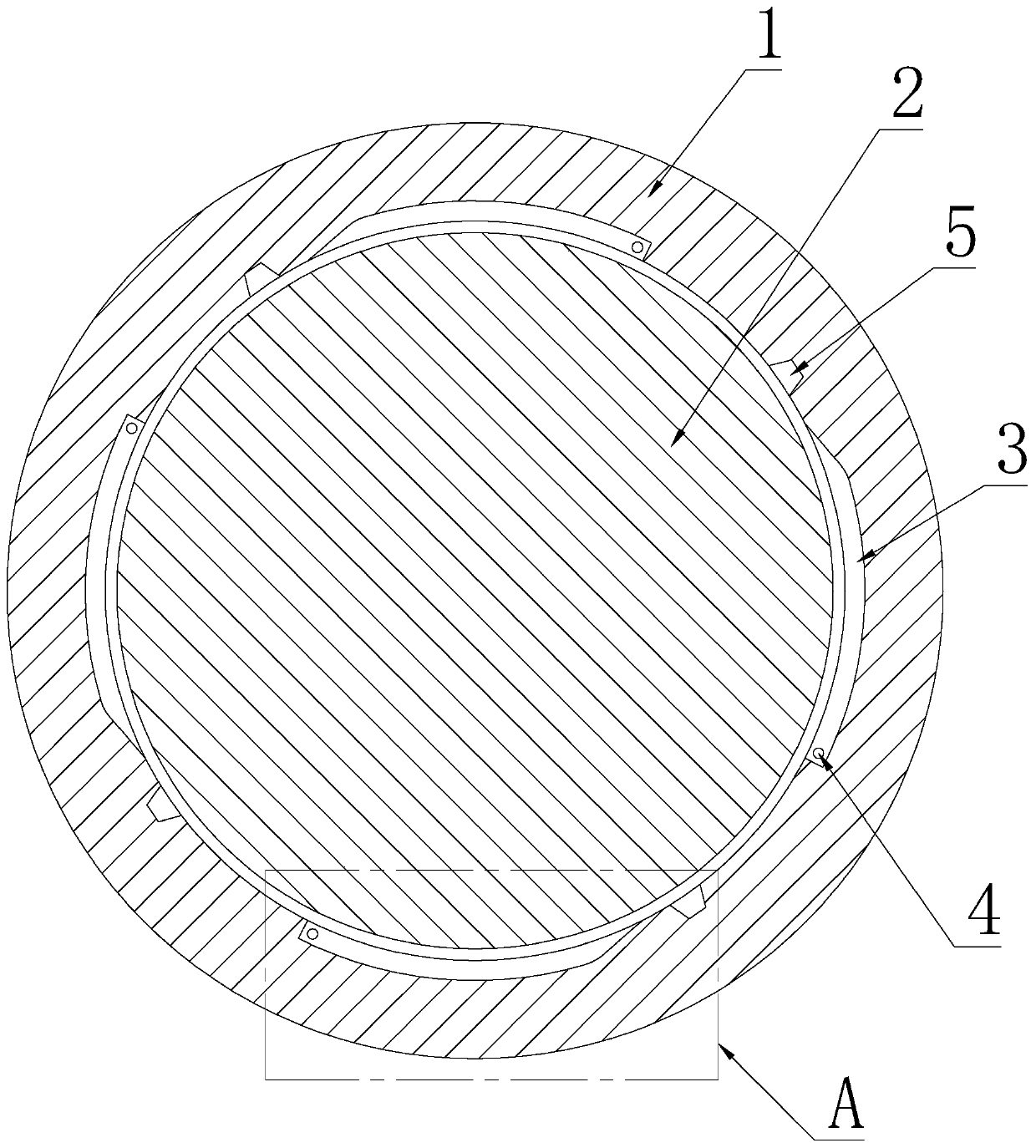

[0035] The invention provides an auxiliary deceleration system comprising such as figure 1 Shown gearbox 6, oil supply system and above-mentioned hydraulic retarder, described stator 1 is fixed on the vehicle frame, and described rotor 2 is connected with transmission shaft 7 of automobile through gearbox 6, and described hydraulic retarder The oil return tank 5 of the force retarder communicates with the input end of the oil supply system, and the oil supply channel 4 of the hydraulic retarder communicates with the output end of the oil supply system. The above-mentioned stator 1 and rotor 2 are accommodated in a casing, and the casing is fixedly installed on the vehicle frame or chassis.

[0036] The gearbox 6 includes a plurality of transmission gear sets, the input gear is called the driving wheel at the beginning, and the output gear is called the end driven wheel. The input shaft and the output shaft of the gearbox 6 are fixedly connected with the drive shaft 7 and the r...

Embodiment 2

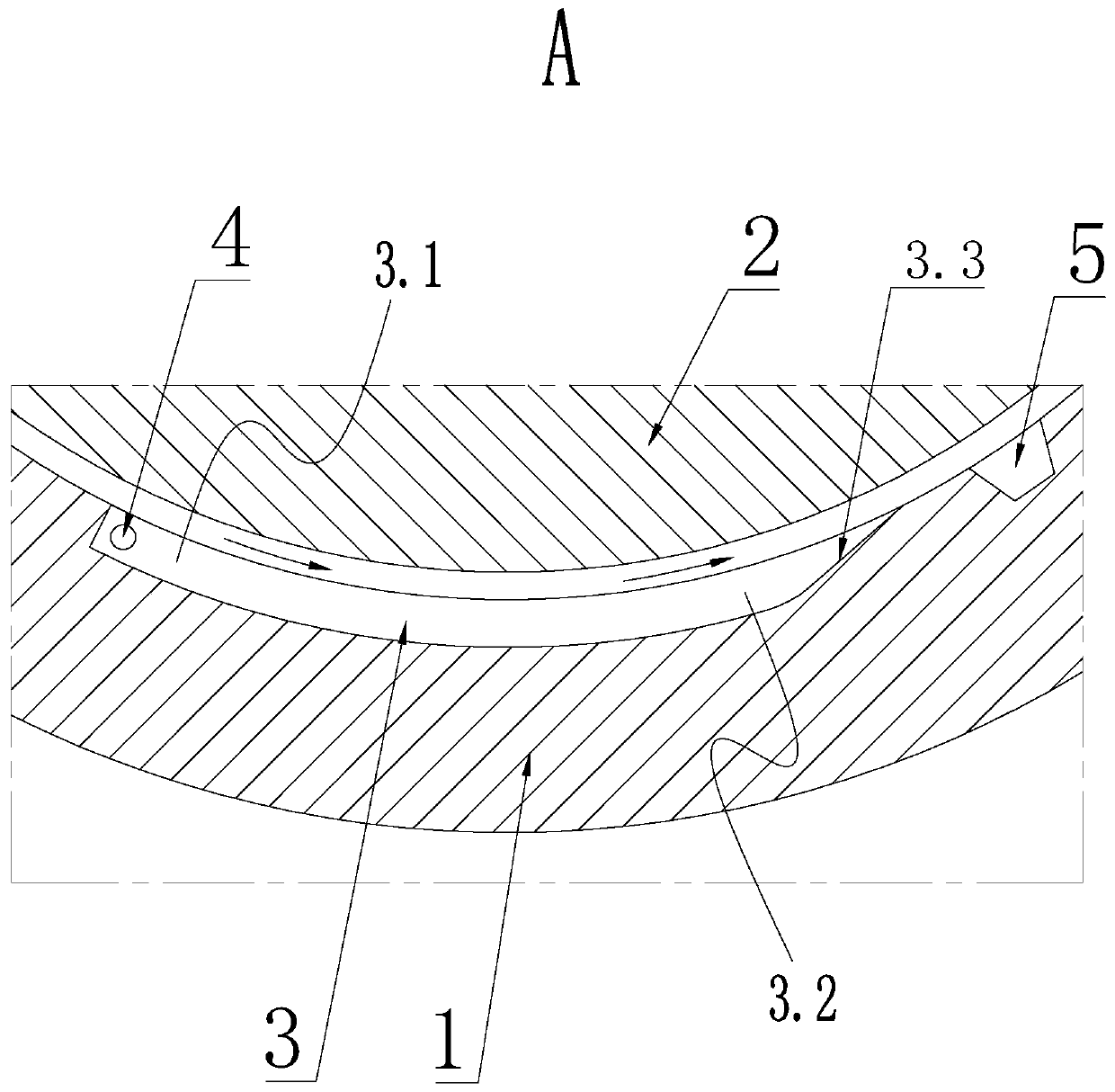

[0042] Such as Figure 4 As shown, the oil supply system includes an oil pump 8, the output end of the oil pump 8 communicates with the oil supply channel 4 on the hydraulic retarder, and the input end of the oil pump 8 communicates with the oil return tank 5 through the oil tank. The oil pump 8, The oil tank and the working oil chamber 3 are sequentially connected through a number of oil pipes 9 to form a circulating oil circuit for circulating oil supply. Increase the oil inlet pressure through the oil pump 8 to avoid a large degree of pressure relief due to the setting of the oil supply channel 4 in the low pressure area, which will affect the pressure maintenance of the oil in the high pressure area 3.2.

[0043] The output end of the above-mentioned oil pump 8 communicates with the oil supply passage 4 on the hydraulic retarder through an oil pipe 9, the input end of the oil pump 8 communicates with the oil outlet of the oil tank through an oil pipe 9, and the oil inlet o...

Embodiment 3

[0066]The gearbox 6 includes a main gearbox 6.1 and a continuously variable transmission 6.2. The input end of the main gearbox 6.1 is connected or disconnected from the drive shaft 7 through a clutch, and the output end of the main gearbox 6.1 is connected to the hydraulic slowdown through the continuously variable transmission 6.2. The rotor 2 of the transmission is connected, and the electronic control module for electrically connecting with the vehicle central control system is provided on the continuously variable transmission 6.2.

[0067] As one of the examples of the third embodiment, the main gearbox 6.1 is used to convert the different speeds of the transmission shaft 7 of the vehicle into a constant speed, and the continuously variable transmission 6.2 converts the constant speed transmitted by the main gearbox 6.1 Adjustment, so as to adjust the load force on the rotor, and finally adjust the damping force applied by the working oil chamber 3 on the rotor 2 to cope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com