Intelligent manufacturing private network data collecting and dispatching system

A data acquisition and intelligent manufacturing technology, applied in control/regulation systems, general control systems, program control, etc., can solve the problems of reducing manufacturing work efficiency, increasing manual labor intensity, and insufficient intelligence, reducing cooperative production, Improve work efficiency and product quality, improve the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

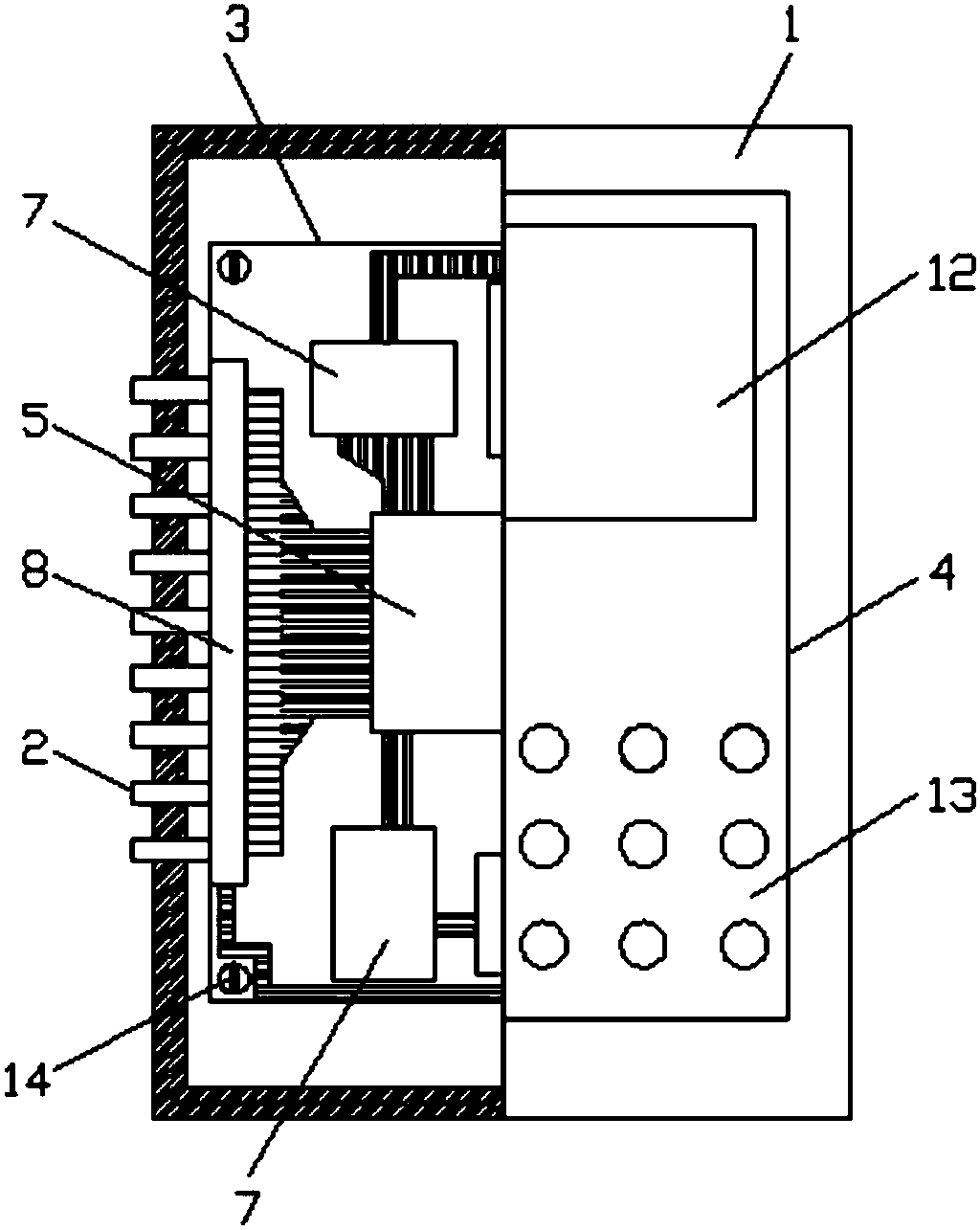

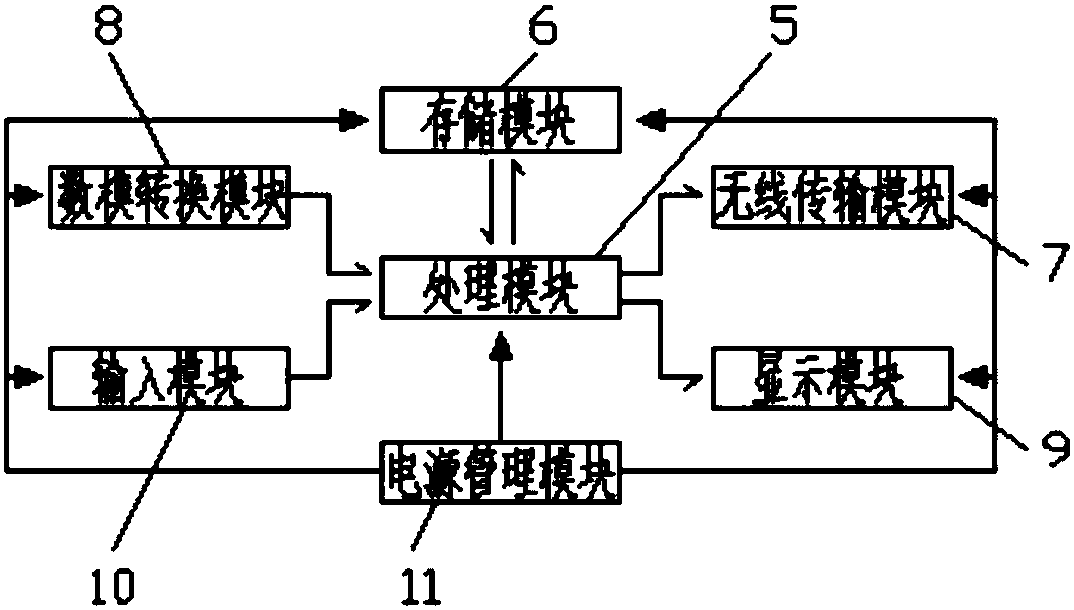

[0016] see Figure 1-2 , the present invention provides a technical solution: an intelligent manufacturing private network data collection and scheduling system, including a housing 1, a connection port 2, a main board 3 and a control panel 4, the main board 3 is located inside the housing 1, and the main board 3 is connected to the The shell 1 is fixedly connected, the wiring port 2 is located on the side wall of the shell 1, the wiring port 2 is welded to the main board 3, the surface of the shell 1 is provided with a control panel 4, and the control panel 4 is fixedly connected to the shell 1 The surface of the mainboard 3 is provided with a processing module 5, a storage module 6, a wireless transmission module 7, a digital-to-analog conversion module 8, a display module 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com