Low-speed electric vehicle brushless motor Hall simulation device

A brushless motor and analog device technology, applied in electromechanical devices, electric vehicles, motor control and other directions, can solve the problems of long maintenance time, the brushless motor controller cannot be recognized, and the brushless motor controller cannot be reversed and rotated. To achieve the effect of improving the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

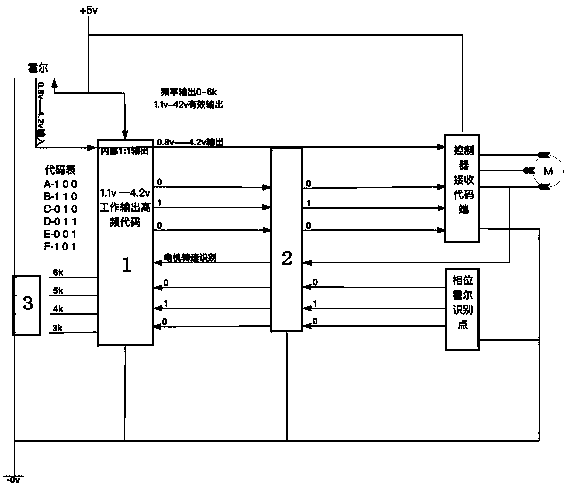

[0018] see figure 1 As shown, a low-speed electric vehicle brushless motor Hall simulation device includes a main control IC1, a driver IC2, and a dial switch S1-S4. The internal integrated components of the simulator are pasted and welded on the PCB board. The dial switches S1-S4 are connected to the main control IC1 through the internal PCB board line, and the main control IC (1) and the driver IC (2) are connected through the internal PCB board line. Connection, the main control IC1 and the Hall throttle are connected to the plug through the cable, the code receiving end of the controller is connected to the driver IC2 through the cable and the plug, and the Hall phase identification point is connected to the driver IC2 through the cable and the plug. connect;

[0019] The main control IC1 outputs high-frequency codes for 1.1v-4.2v work;

[0020] The main control IC1 is responsible for the acquisition of the accelerator Hall voltage, the acquisition of the Hall phase sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com