Compression device and separation method for controlling mass flow

A technology for controlling quality and mass flow, which is applied in the field of refrigerant devices, and can solve problems such as lowering of refrigerant density, higher temperature of hot gas, and lower volumetric efficiency of compressors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

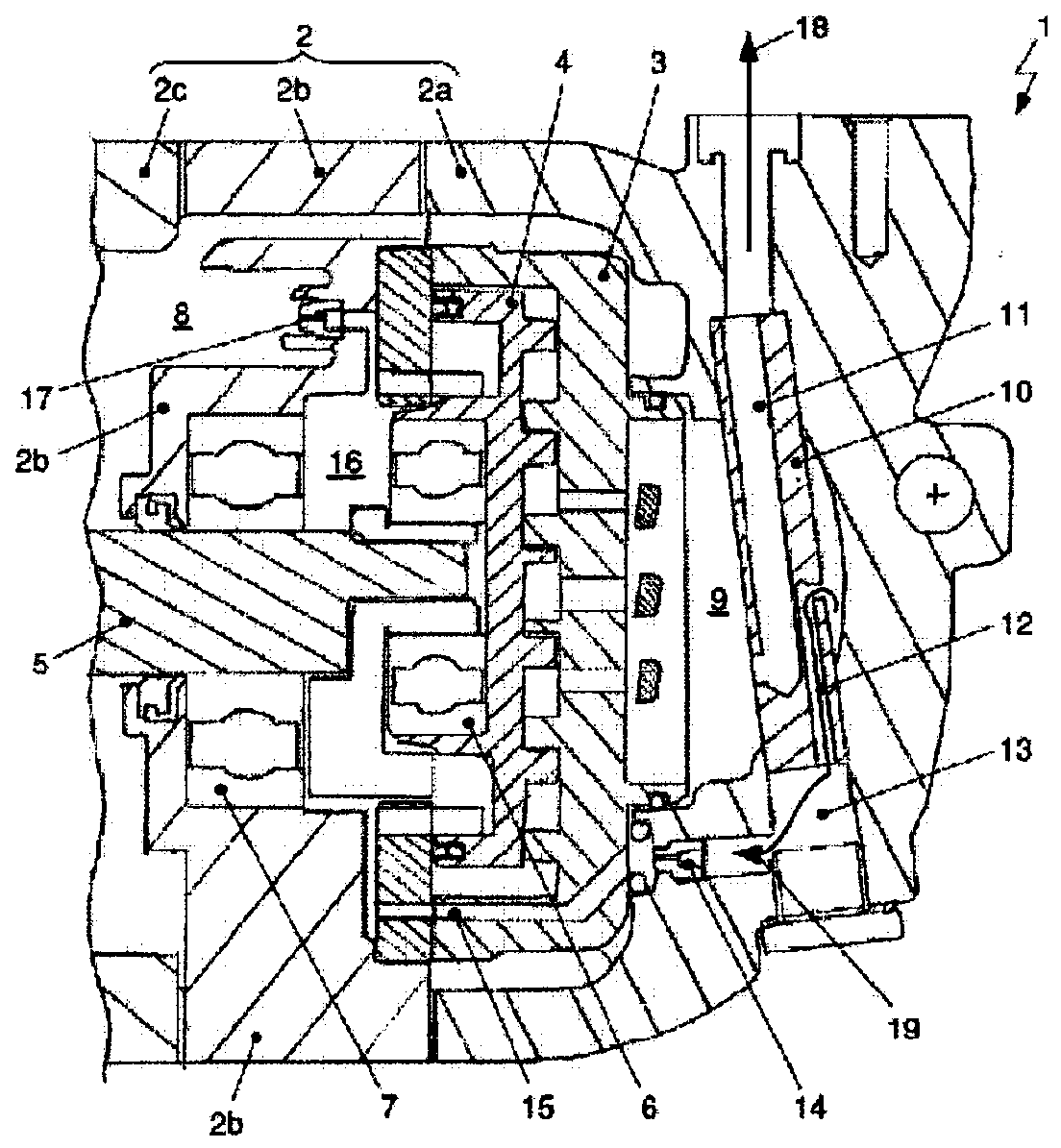

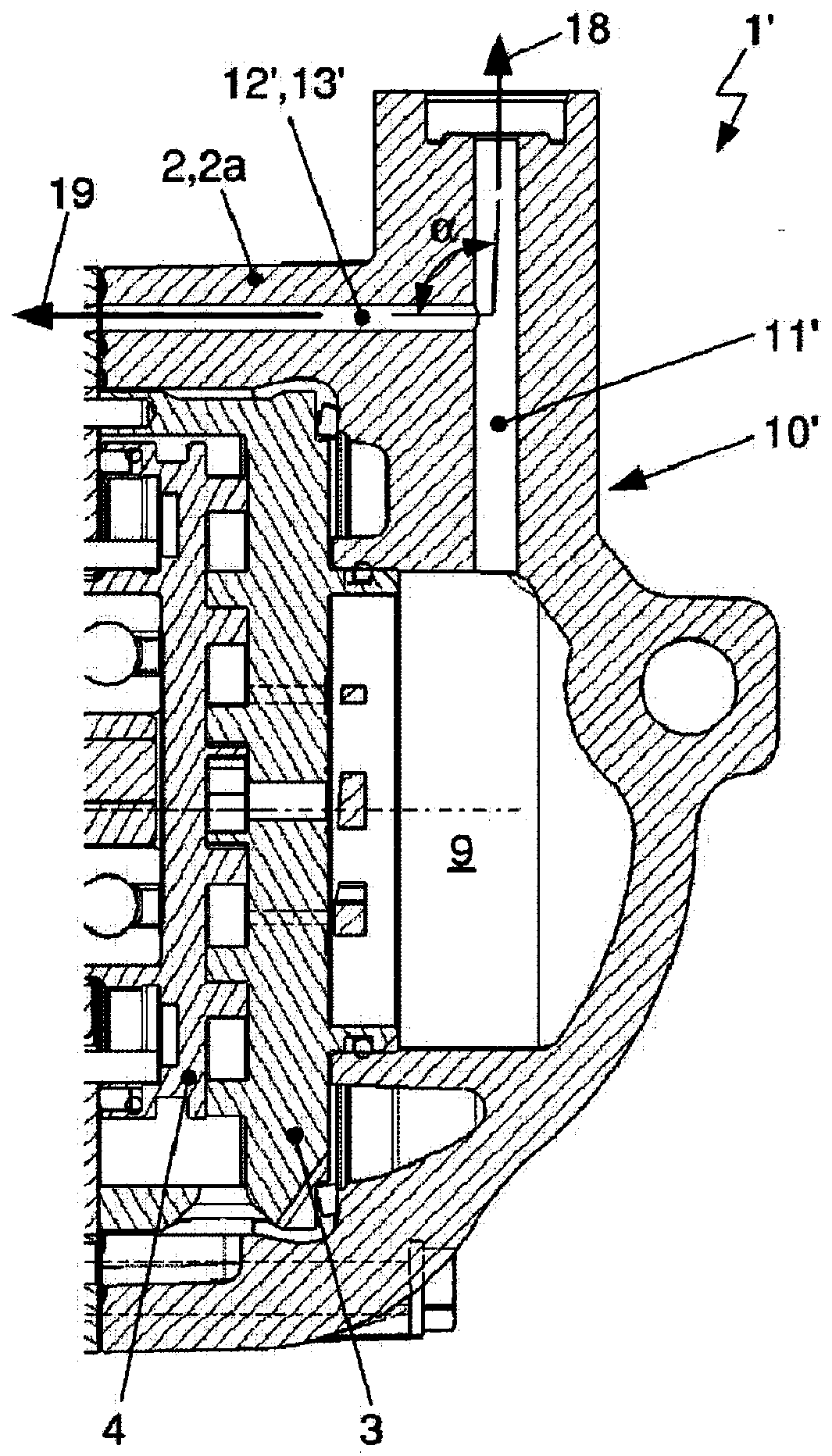

[0050] figure 1 The compressor 1 is shown in cross-section with a structure 10 for separating the mass flow control, also referred to below as separator 10 . In addition, the compressor 1 also includes a compression mechanism for sucking, compressing, and discharging refrigerant as a gaseous fluid including oil as a lubricant for lubrication. The compression mechanism and the separator 10 are arranged inside the housing 2 .

[0051] The compressor 1 is realized as a scroll compressor, wherein a rear housing element 2 a , a middle housing element 2 b and a front housing element 2 c form a housing 2 in the assembled state. The compression mechanism of the compressor 1 includes a stationary stator 3 and a movable orbiter 4 each having a base plate and being formed in a scroll form and extending from the base plate. extended wall. The base plates are arranged relative to each other such that the walls are interlocked. The stationary stator 3 is realized in the housing 2 or as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com