Method and system for measuring sulfur solubility in gas

A solubility, equilibrium solubility technology, applied in gas fuels, measuring devices, weighing, etc., can solve problems such as impracticality, cost, time, safety problems and complexity troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The following examples are provided to better illustrate embodiments of the invention, but should not be construed as limiting the scope of the invention.

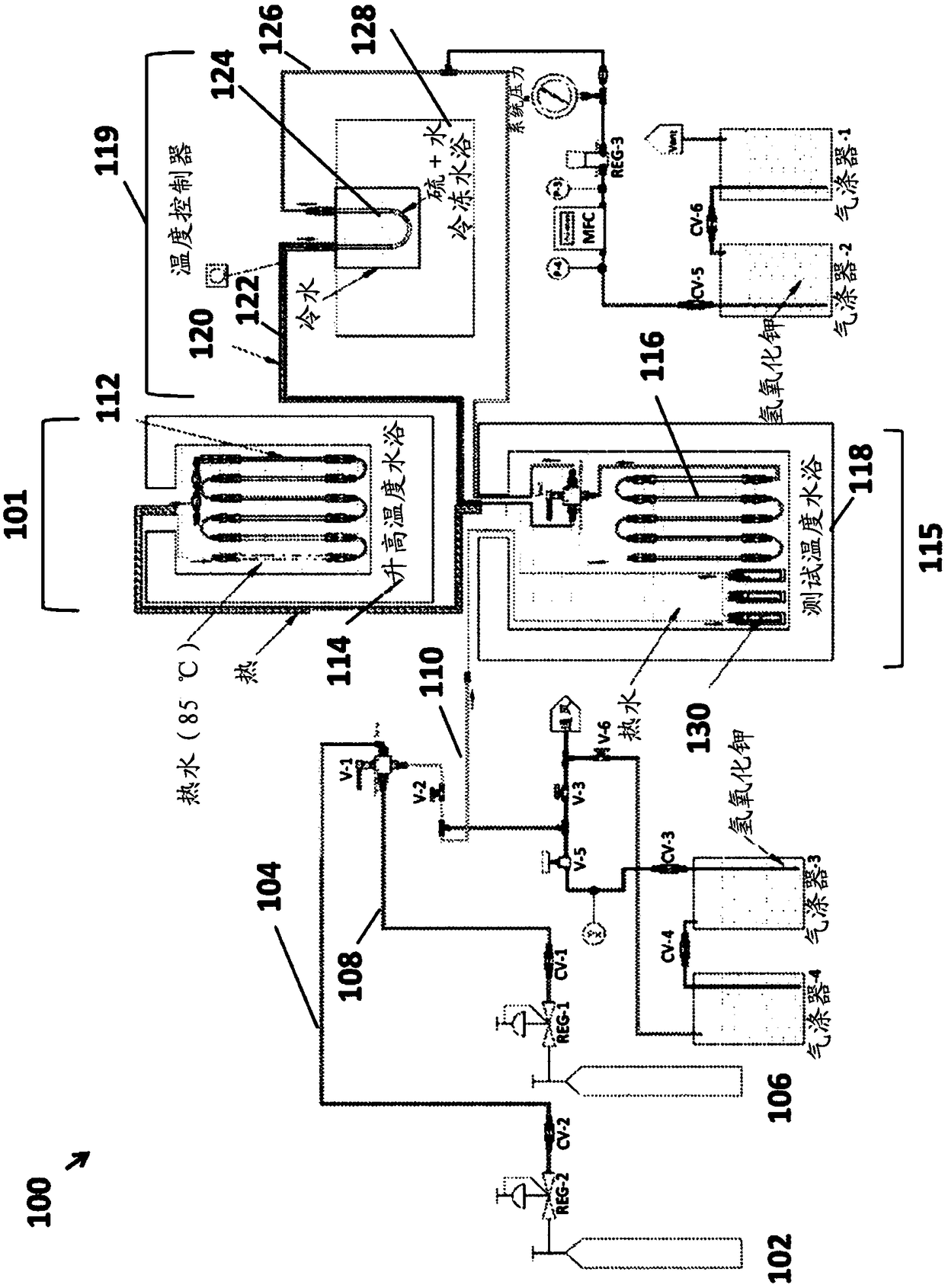

[0052] In these examples, five test runs were performed, and the test gas used for each test run was methane (CH4). As shown in Table 1 (below), the test temperature was varied between 30°C and 70°C and the test pressure was varied between 300 psia and 1000 psia for five test runs. The high temperature water bath (first station) was set to 85°C, and the test temperature water bath (second station) was set to the required test temperature (see Table 1 for the test temperature of each run). The pressure of the system was also set to the desired test pressure (see Table 1 for test pressures for each run).

[0053] Each test run was performed using the following scheme (see figure 1 ):

[0054] First turn on the tube heating (heat controller). Next, evaluate the three water baths to make sure the water levels are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com