Beef back straps and making method thereof

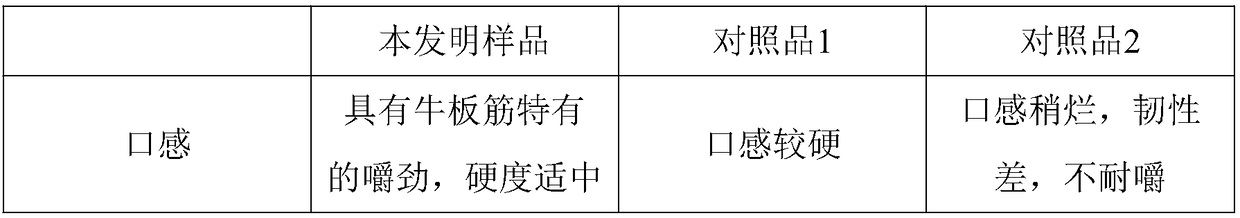

A technology of beef tendon and seeds, applied in the direction of food ingredients as taste improver, food ingredients as taste improver, food science, etc. Improve acceptability, good tenderization effect, good effect of removing beef odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of beef tendon, its composition and parts by weight are as follows:

[0038] 60 parts of fermented beef tendon, 5 parts of spicy oil, 2 parts of chopped spicy pepper, 1 part of salt, 1 part of white sugar, 0.3 part of monosodium glutamate.

[0039] Wherein, the preparation method of described fermented beef tendon is as follows:

[0040] (1) Pretreatment of raw materials: After the beef tendon is cleaned in running water, put it into boiling water to cook for 5-10 minutes, and remove the surface impurities after removing it;

[0041] (2) Cooking: Put the beef tendon in step (1) into boiling water, cook for 1-2 hours, then take it out and cool it to below 60°C, cut the beef tendon into long strips by longitudinal cutting, and then cut it into 2-4cm beef. Spare plate section;

[0042] (3) Fermentation: add 2-10% inulin by weight to the beef tendon segment prepared in step (2), mix evenly, add liquid seeds, the inoculation amount is 3-10%, mix evenly, and ferment,...

Embodiment 2

[0059] A kind of beef tendon, its composition and parts by weight are as follows:

[0060] 80 parts of fermented beef tendon, 8 parts of spicy oil, 3 parts of crushed spicy pepper, 3 parts of salt, 3 parts of white sugar, 2 parts of monosodium glutamate.

[0061] Wherein, the preparation method of described fermented beef tendon is as follows:

[0062] (1) Pretreatment of raw materials: After the beef tendon is cleaned in running water, put it into boiling water to cook for 5-10 minutes, and remove the surface impurities after removing it;

[0063] (2) Cooking: Put the beef tendon in step (1) into boiling water, cook for 1-2 hours, then take it out and cool it to below 60°C, cut the beef tendon into long strips by longitudinal cutting, and then cut it into 2-4cm beef. Spare rib section;

[0064] (3) Fermentation: add 2-10% by weight of inulin to the beef tendon segment prepared in step (2), mix well, add liquid seeds, the inoculation amount is 3-10%, mix well, and ferment, a...

Embodiment 3

[0070] A kind of beef tendon, its composition and parts by weight are as follows:

[0071] 90 parts of fermented beef tendon, 10 parts of chili oil, 4 parts of chopped spicy pepper, 5 parts of salt, 1 part of white sugar, 1 part of monosodium glutamate.

[0072] Wherein, the preparation method of described fermented beef tendon is as follows:

[0073] (1) Raw material pretreatment: After the beef tendon is cleaned in running water, it is put into boiling water and boiled for 10 minutes, and the surface impurities are removed after being pulled out;

[0074] (2) Cooking: put the beef tendon in step (1) into boiling water, cook for 1 hour, then take out and cool to below 60°C, cut the beef tendon into long strips by longitudinal cutting, and then cut into 2cm beef Spare rib section;

[0075] (3) Fermentation: add 5% inulin by weight to the beef tendon section obtained in step (2), mix well, add liquid seeds, the inoculum size is 6%, mix well, and ferment, and the fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com