Production processing device of organic compound fertilizer

A technology of processing device and compound fertilizer, which is applied to mixers, mixers, mixer accessories and other directions with rotary mixing devices, can solve the problems of high price, heavy workload and high procurement cost, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

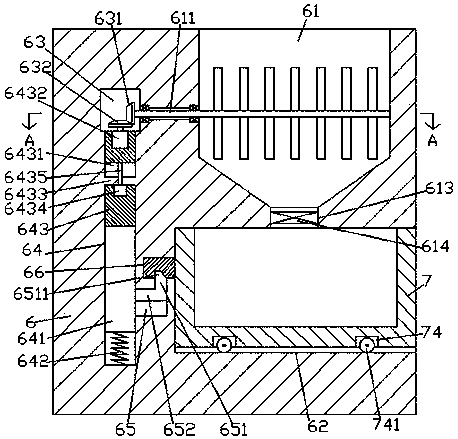

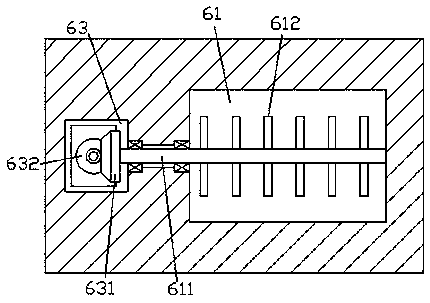

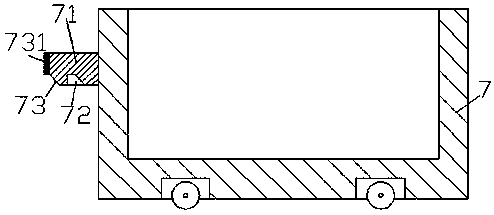

[0012] Combine below Figure 1-3 The present invention will be described in detail.

[0013] refer to Figure 1-3 According to an embodiment of the present invention, a production and processing device for organic compound fertilizers includes a main body 6 and a storage box 7, a mixing chamber 61 with an upward opening is arranged in the top end surface of the main body 6, and the main body 6 The right end face is provided with a placement groove 62 opening to the right, and the left extension of the placement groove 62 is located at the opposite position to the bottom of the mixing chamber 61, and the mixing chamber 61 is connected to the part between the placement groove 62 There is a discharge trough 613, and the main body 6 on the left side of the mixing chamber 61 is provided with a transmission chamber 63, and the inner bottom wall of the transmission chamber 63 is connected with a guide chute 64 extending downward. The bottom extension section of the guide chute 64 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com