Reclaimed rubber sound insulation concrete and preparation method

A technology for recycling rubber and concrete, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficult digestion of resources, landfill occupation, harmful pollution, etc., achieve high noise reduction coefficient, improve porosity degree, the effect of reducing the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

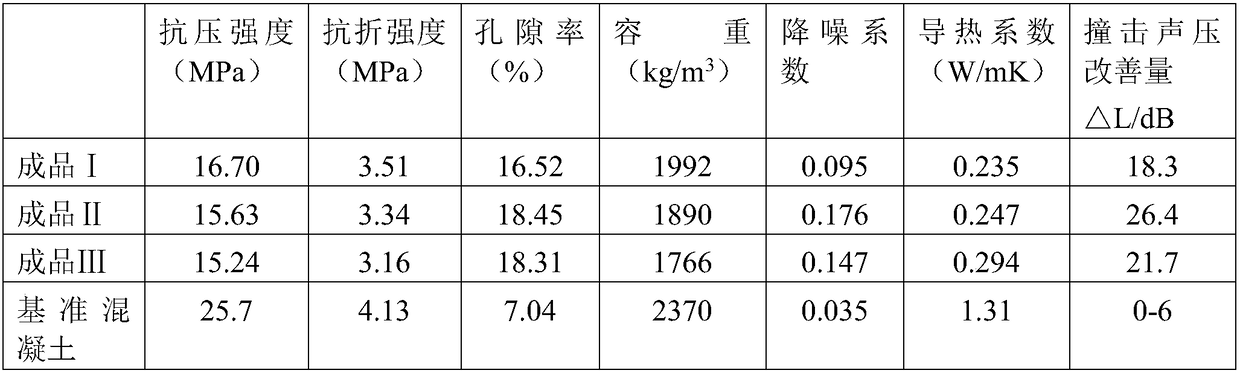

Embodiment 1

[0042] A recycled rubber sound insulation concrete, including the following components per unit volume mass: cement 360kg / m 3 , composite mineral admixture 70kg / m 3 , recycled rubber aggregate 261kg / m 3 , fine aggregate 710kg / m 3 , coarse aggregate 438kg / m 3 , admixture 2.58kg / m 3 And water 150kg / m 3 .

[0043] Ordinary Portland cement is used as cement, with a strength grade of 42.5MPa, an initial setting time of 180 minutes, and a final setting time of 230 minutes.

[0044] The composite mineral admixture accounts for 20%-25% of the amount of cement, and the composite mineral admixture is a low-maturity active mineral material, which includes fly ash, slag powder and iron tailings fine powder, of which SiO 2 、Al 2 o 3 and Fe 2 o 3 The total mass fraction is ≥70%, the activity index is 91%, the stability meets the requirements, and the 45μm square hole sieve residue is ≤30%.

[0045] The source of raw materials for recycled rubber aggregates is waste automobile tir...

Embodiment 2

[0052] A recycled rubber sound insulation concrete, including the following components per unit volume mass: cement 360kg / m 3 , composite mineral admixture 91kg / m 3 , recycled rubber aggregate 355kg / m 3 , fine aggregate 704kg / m 3 , coarse aggregate 328kg / m 3 , admixture 2.78kg / m 3 And water 160kg / m 3 .

[0053] Ordinary Portland cement is used as cement, with a strength grade of 42.5MPa, an initial setting time of 180 minutes, and a final setting time of 230 minutes.

[0054] The composite mineral admixture accounts for 20%-25% of the cement content, and the composite mineral admixture is a low-maturity active mineral material. The low-maturity active mineral material includes fly ash, slag powder and iron tailings fine powder, and its SiO 2 、Al 2 o 3 and Fe 2 o 3 The total mass fraction is ≥70%, the activity index is 91%, the stability meets the requirements, and the 45μm square hole sieve residue is ≤30%.

[0055] The source of raw materials for recycled rubber ag...

Embodiment 3

[0062] A recycled rubber sound-insulating concrete, including the following components per unit volume mass: cement 315kg / m 3 , composite mineral admixture 73kg / m 3 , recycled rubber aggregate 347kg / m 3 , fine aggregate 660kg / m 3 , coarse aggregate 221kg / m 3 , admixture 2.91kg / m 3 And water 147kg / m 3 .

[0063] Ordinary Portland cement is used as cement, with a strength grade of 42.5MPa, an initial setting time of 180 minutes, and a final setting time of 230 minutes.

[0064] The composite mineral admixture accounts for 20%-25% of the cement content, and the composite mineral admixture is a low-maturity active mineral material. The low-maturity active mineral material includes fly ash, slag powder and iron tailings fine powder, and its SiO 2 、Al 2 o 3 and Fe 2 o 3 The total mass fraction is ≥70%, the activity index is 91%, the stability meets the requirements, and the 45μm square hole sieve residue is ≤30%.

[0065] The source of raw materials for recycled rubber ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com