Reinforced cement-based grouting material

A technology of cement-based and grouting materials, which is applied in the field of reinforced cement-based grouting materials and reinforcement grouting materials. The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

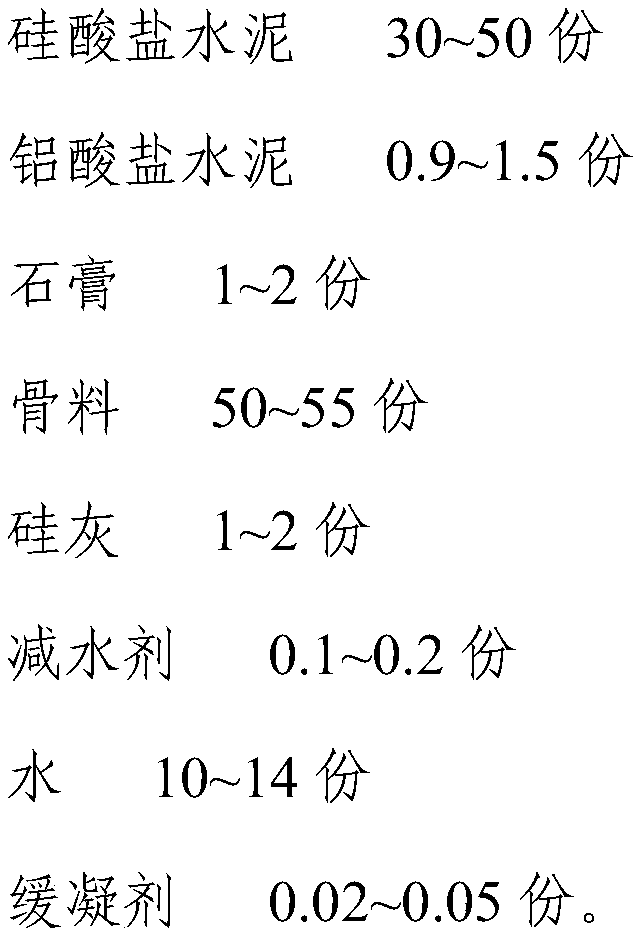

[0028] This embodiment discloses a reinforced cement-based grouting material, which includes the following components in parts by weight, 30.8 parts of Portland cement with a model of 52.5R, 1 part of aluminate cement, and α-hemihydrate gypsum 1.5 parts, 53 parts of aggregate, 1.5 parts of silica fume, 0.15 parts of polycarboxylate superplasticizer, 12 parts of water, 0.05 parts of sodium gluconate.

[0029] Among them, aluminate cement requires that the content of alumina accounts for 45% to 55%, and the effect is the best at 50%; the content of silica in silica fume is greater than 90%; the polycarboxylate water reducer purchased by Sika company, the entire The water reduction rate in the process is 25% to 30%.

[0030] Aggregate is river sand composed of multi-grain grades. According to parts by weight, the aggregate includes the following components,

[0031] 8 to 10 parts of sand with a particle size of 0.3mm to 0.6mm

[0032] 15 to 20 parts of sand with a particle size...

Embodiment 2

[0037] This embodiment discloses a reinforced cement-based grouting material, which differs from Embodiment 1 only in that the proportions of the components are different. The specific proportions of the components in this embodiment are as follows:

[0038] Portland cement 52.5R 29.87 parts, aluminate cement 1.5 parts, α-hemihydrate gypsum 2 parts, aggregate 53 parts, silica fume 1.2 parts, polycarboxylate superplasticizer 0.13 parts, water 12 parts, Sodium gluconate 0.05 parts. The content of alumina in aluminate cement is required to account for 45% to 55%, and the effect is the best at 50%; the content of silicon dioxide in silica fume is greater than 90%; the polycarboxylate water reducer purchased by Sika company, during the whole process The water reduction rate is 25% to 30%.

[0039] Aggregate is river sand composed of multi-grain grades. According to parts by weight, the aggregate includes the following components,

[0040] 8 to 10 parts of sand with a particle siz...

Embodiment 3

[0044] This embodiment discloses a reinforced cement-based grouting material, which differs from Embodiment 1 only in that the proportions of the components are different. The specific proportions of the components in this embodiment are as follows:

[0045] Portland cement 52.5R 30.4 parts, aluminate cement 1.0 parts, α-hemihydrate gypsum 1.5 parts, aggregate 53 parts, silica fume 1.9 parts, polycarboxylate superplasticizer 0.15 parts, water 12 parts, Sodium gluconate 0.05 parts. The content of alumina in aluminate cement is required to account for 45% to 55%, and the effect is the best at 50%; the content of silicon dioxide in silica fume is greater than 90%; the polycarboxylate water reducer purchased by Sika company, during the whole process The water reduction rate is 25% to 30%.

[0046] Aggregate is river sand composed of multi-grain grades. According to parts by weight, the aggregate includes the following components,

[0047] 8 to 10 parts of sand with a particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com