Fischer-Tropsch synthesized residue wax passivation technology and device

A technology of Fischer-Tropsch synthesis and slag wax, which is applied in the direction of petrochemical modification, etc., can solve the problems of wasting resources, polluting the environment, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

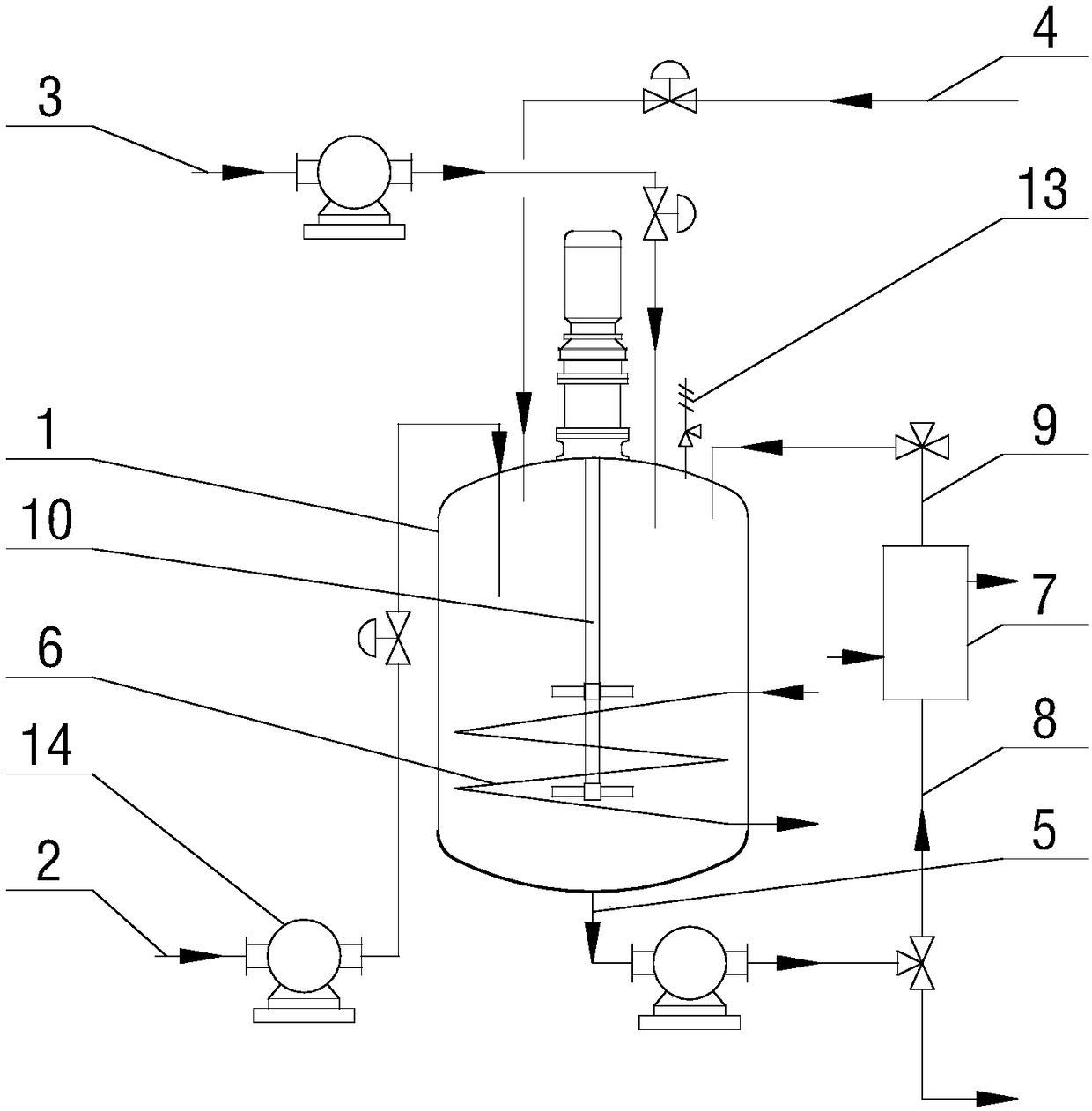

Embodiment 1

[0037] Embodiment 1: raw material is 18.4 tons of Fischer-Tropsch synthesis slag wax (wherein the iron-based catalyst content of II valence iron is 8%), and oxygenant is MnO 2 , the amount of oxidant used is about 1.143 tons, and the initial temperature T1 is 190°C. In the above-mentioned device A, the passivation reaction is carried out according to the above-mentioned passivation process, and after the reaction, the content of the iron-based catalyst of II-valent iron decreases to 0.8%.

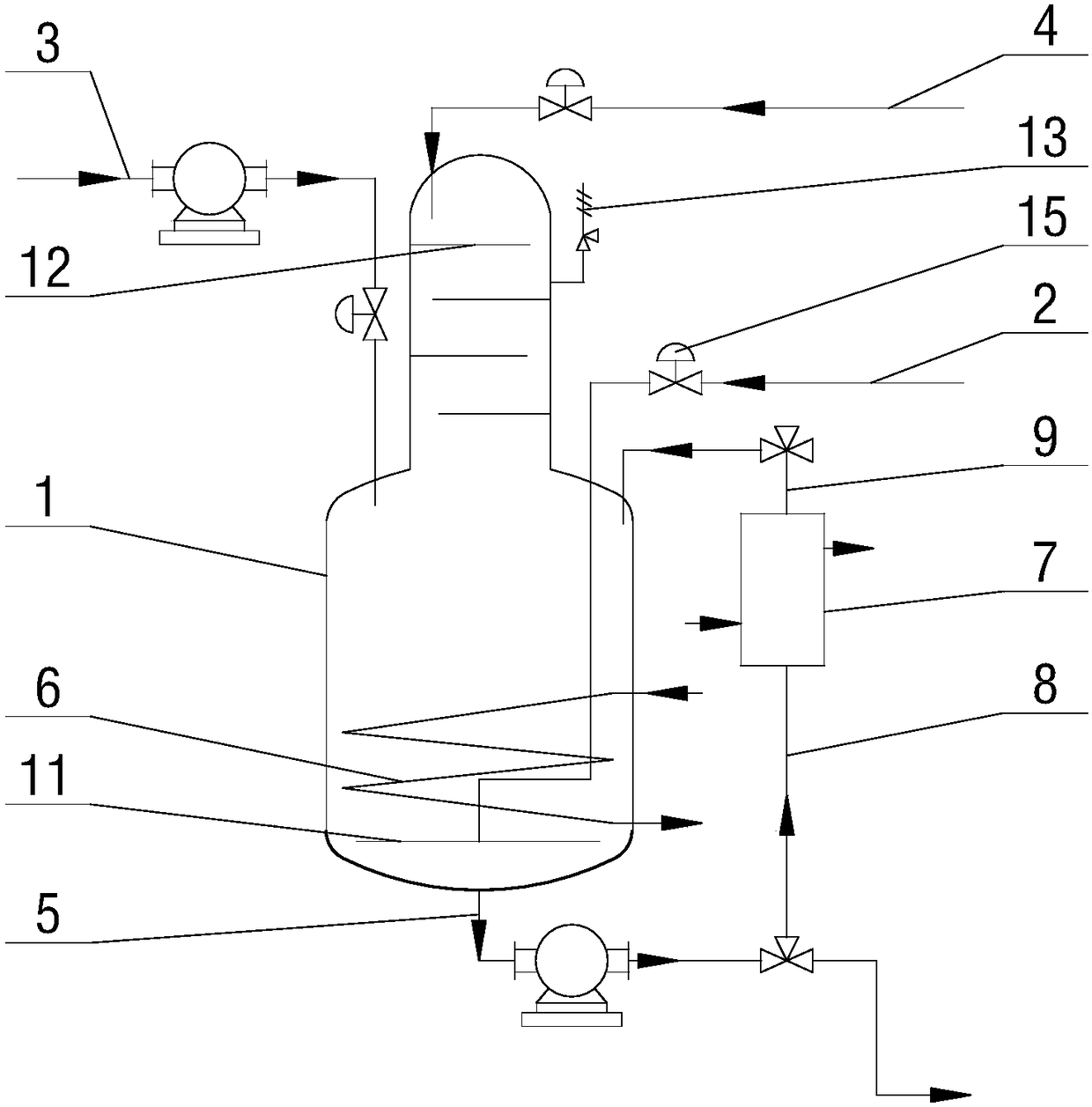

Embodiment 2

[0038] Embodiment 2: raw material is 50 tons of Fischer-Tropsch synthesis slag wax (wherein the iron-based catalyst content of II valence iron is 45%), oxygenant is O 2 , the oxygen consumption is about 3.213 tons, and the initial temperature T1 is 140°C. In the above-mentioned device B, the passivation reaction is carried out according to the above-mentioned passivation process, and after the reaction, the content of the iron-based catalyst of II-valent iron is reduced to 0.3%.

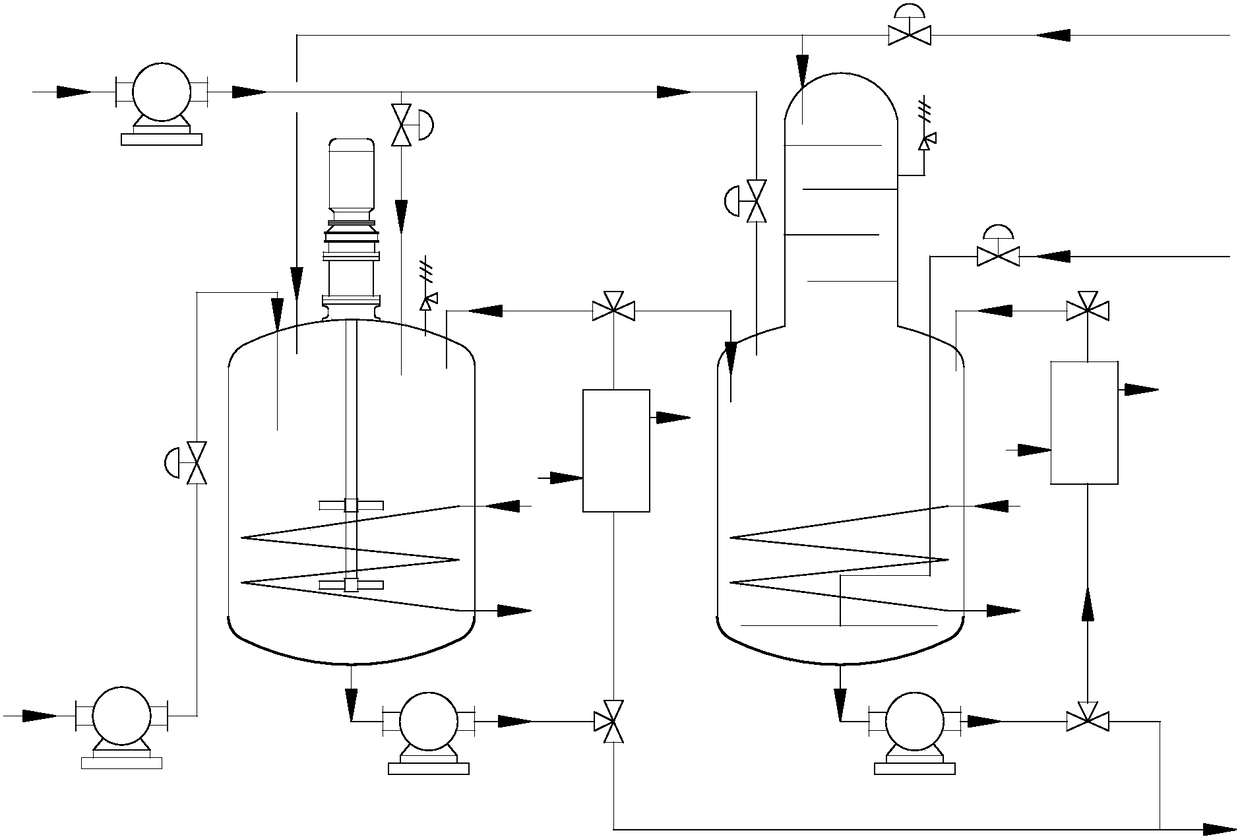

Embodiment 3

[0039] Embodiment 3: raw material is 19.4 tons of Fischer-Tropsch synthesis slag wax (wherein the iron-based catalyst content of II valence iron is 60%), oxygenant is O 2 and KMnO 4 And according to the mass ratio of 7:1, the oxygen consumption is about 2.104 tons, KMnO 4 The amount used is about 0.3 tons, and the initial temperature T1 is 150°C. in the attached image 3 In the shown series device, the passivation reaction is carried out according to the above-mentioned passivation process. The reacted material in device A is poured into device B, and the passivation reaction is carried out according to the above-mentioned passivation process. After the reaction, the iron of II-valent iron The content of base catalyst was reduced to 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com