Microchannel plate with ultralow-temperature stable resistance-temperature characteristic and fabrication method thereof

A technology of temperature resistance characteristics and micro-channel plate, which is applied in the manufacture of light-emitting cathodes, secondary emitter electrodes, electrode devices with multiple dynodes, etc., can solve the problem of reducing the resistance of the micro-channel plate and the high resistance of the micro-channel quantum signal Fast reading and other issues to achieve the effect of improving the stability of temperature resistance coefficient, reducing ultra-low temperature body resistance, and fast signal reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

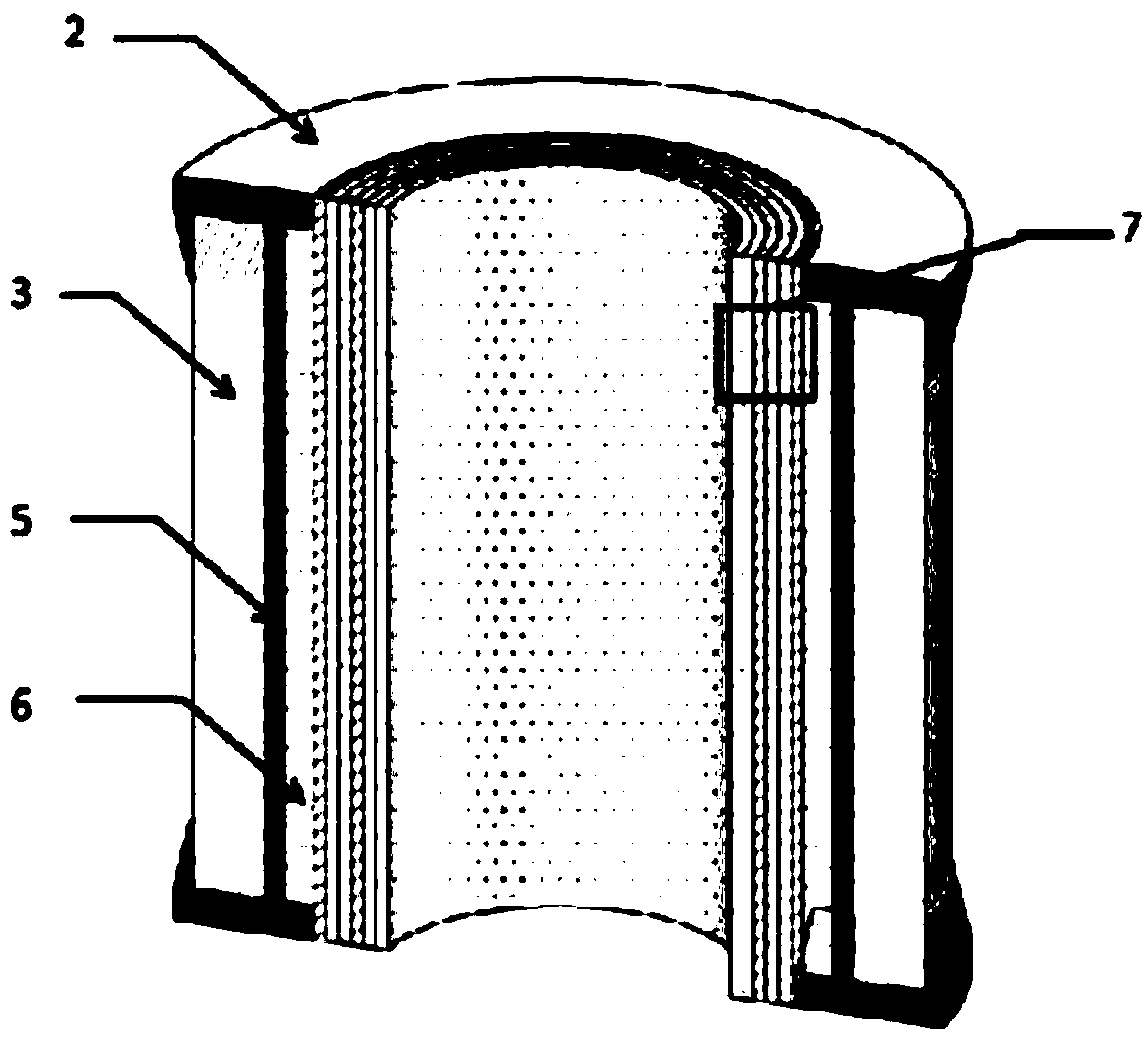

[0048] An embodiment of the present invention proposes a method for preparing a microchannel plate with ultra-low temperature stable temperature resistance characteristics, which includes:

[0049] preparing a conductive layer on the inner wall of the microchannel plate substrate;

[0050] preparing a secondary electron emission layer on the conductive layer;

[0051] A temperature-resistance property modified layer is prepared on the secondary electron emission layer to obtain a microchannel plate with ultra-low temperature stable temperature resistance property.

[0052] The conductive layer and the secondary electron emission layer are formed in situ or directly plated.

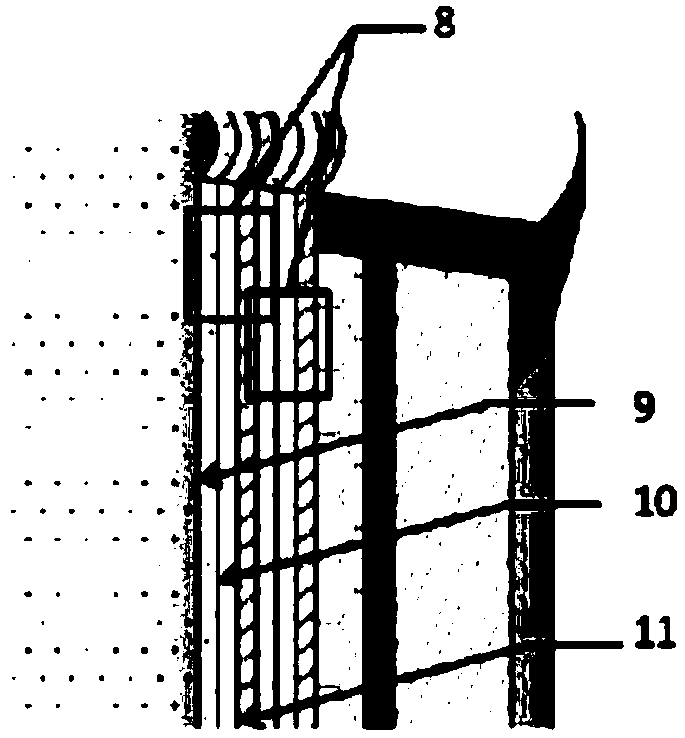

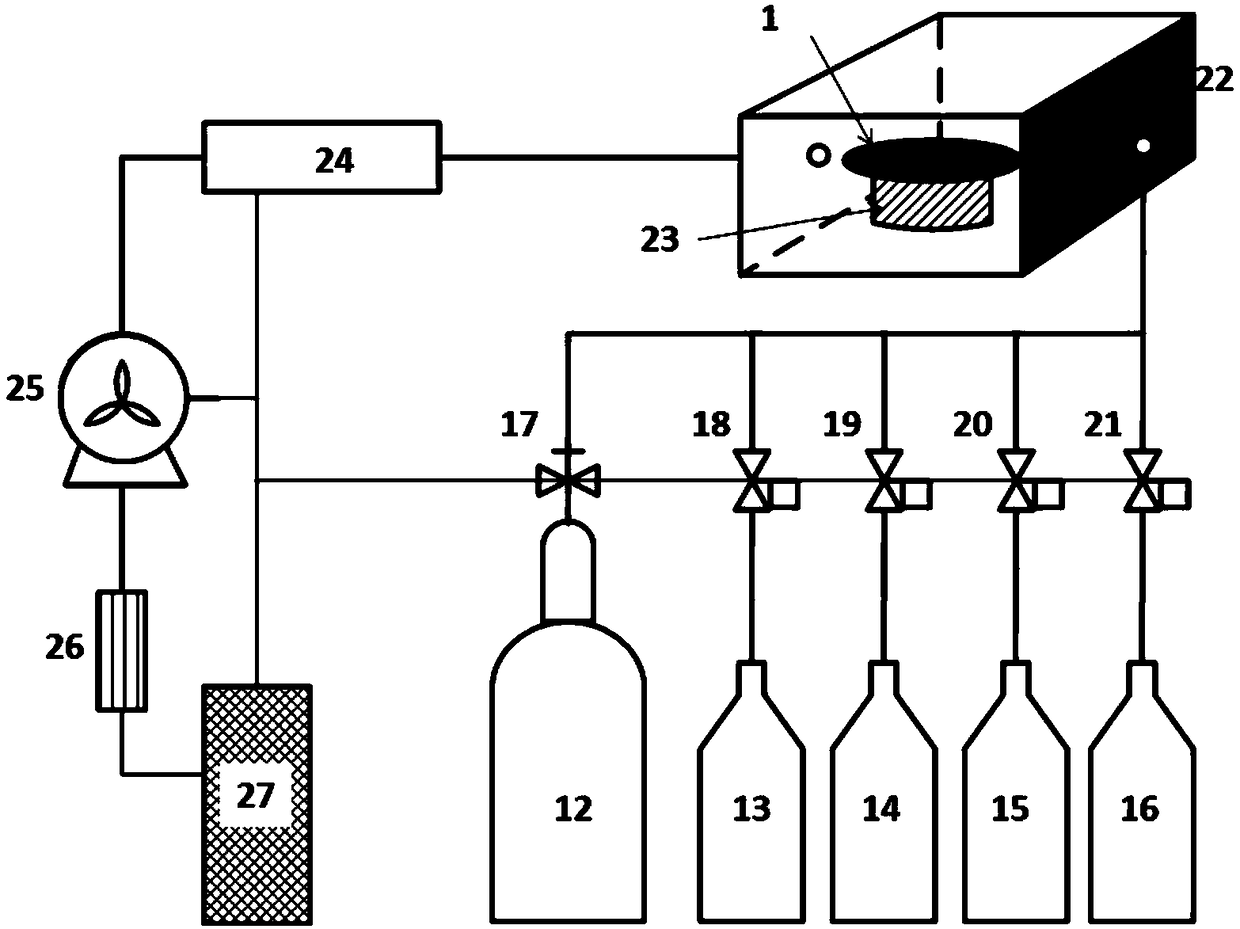

[0053] The preparation of the temperature resistance characteristic modification layer includes: ultrasonically cleaning the micro-channel plate substrate, placing it in a vacuum reaction chamber for atomic layer deposition, using clean gas to continuously clean, keeping the pressure in the reaction chamb...

Embodiment 1

[0072] An embodiment of the present invention proposes a method for preparing a microchannel plate with ultra-low temperature stable temperature resistance characteristics, which includes:

[0073] Select a material suitable for preparing millions of micron-scale apertures with independent hollow channels as the micro-channel plate substrate; the upper and lower surfaces of the substrate are plated with Ni / Cr surface electrodes;

[0074] preparing a conductive layer on the inner wall of the microchannel plate substrate;

[0075] preparing a secondary electron emission layer on the conductive layer;

[0076] Prepare a temperature resistance characteristic modified layer on the secondary electron emission layer: ultrasonically clean the microchannel plate substrate, then perform ultrasonication on the microchannel plate substrate for 10 minutes with acetone and 10 minutes with isopropanol, and bake in an oven at 95°C for 30 minutes , placed in the vacuum reaction chamber for atom...

Embodiment 2

[0098] An embodiment of the present invention proposes a method for preparing a microchannel plate with ultra-low temperature stable temperature resistance characteristics, which includes:

[0099] Select a material suitable for preparing millions of micron-scale apertures with independent hollow channels as the micro-channel plate substrate; the upper and lower surfaces of the substrate are plated with Ni / Cr surface electrodes;

[0100] preparing a conductive layer on the inner wall of the microchannel plate substrate;

[0101] preparing a secondary electron emission layer on the conductive layer;

[0102] Prepare a temperature resistance characteristic modified layer on the secondary electron emission layer: ultrasonically clean the microchannel plate substrate, then perform ultrasonication on the microchannel plate substrate for 10 minutes with acetone and 10 minutes with isopropanol, and bake in an oven at 95°C for 30 minutes , placed in the vacuum reaction chamber for at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com