Ladle bottom lining structure of hot metal ladle with spherical bottom and construction method thereof

A ladle and inner lining technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of difficult construction control, difficult inner lining masonry, and loose combination, so as to prevent iron seepage and Hidden danger of iron seepage, convenient effect of masonry construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

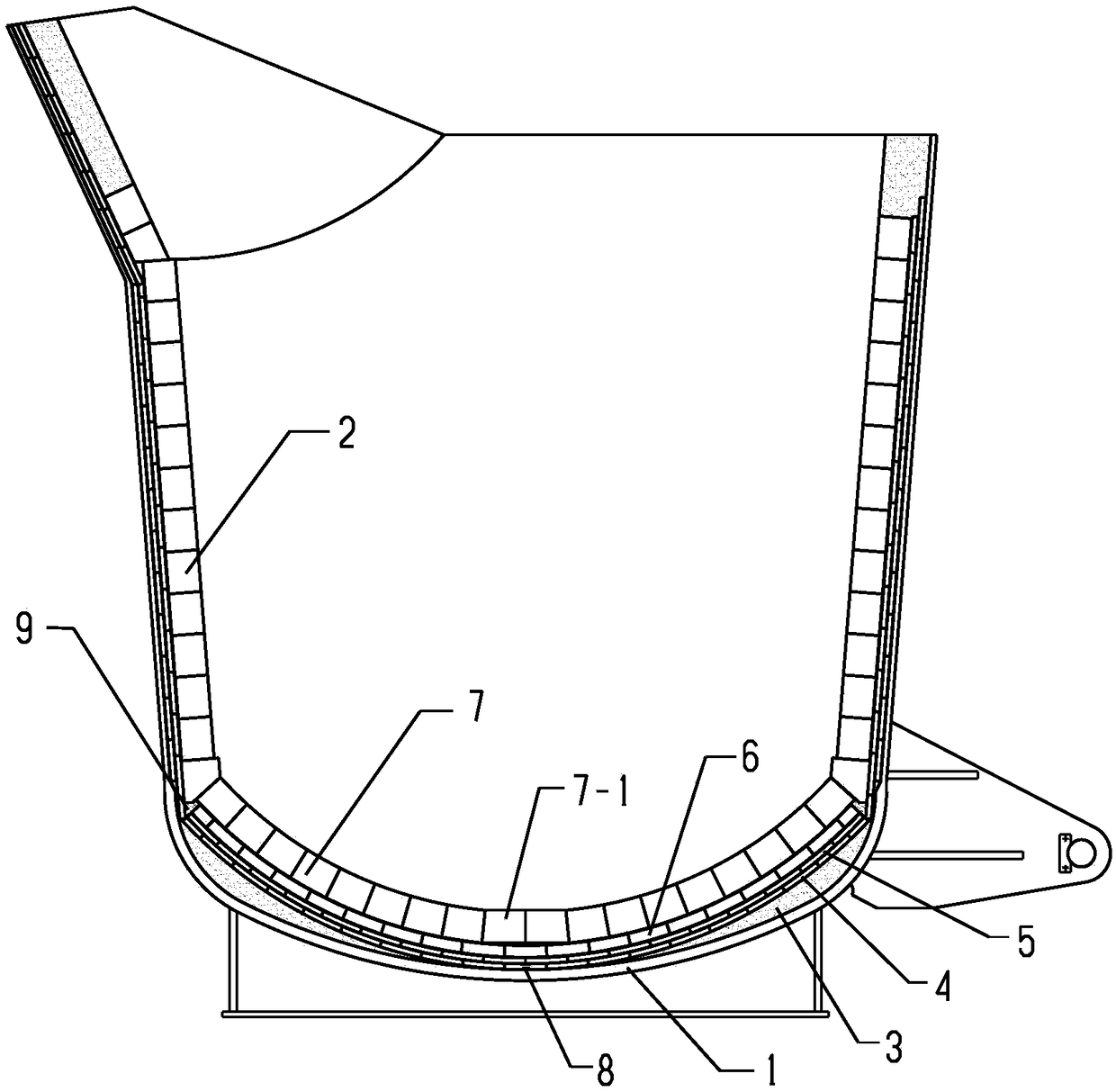

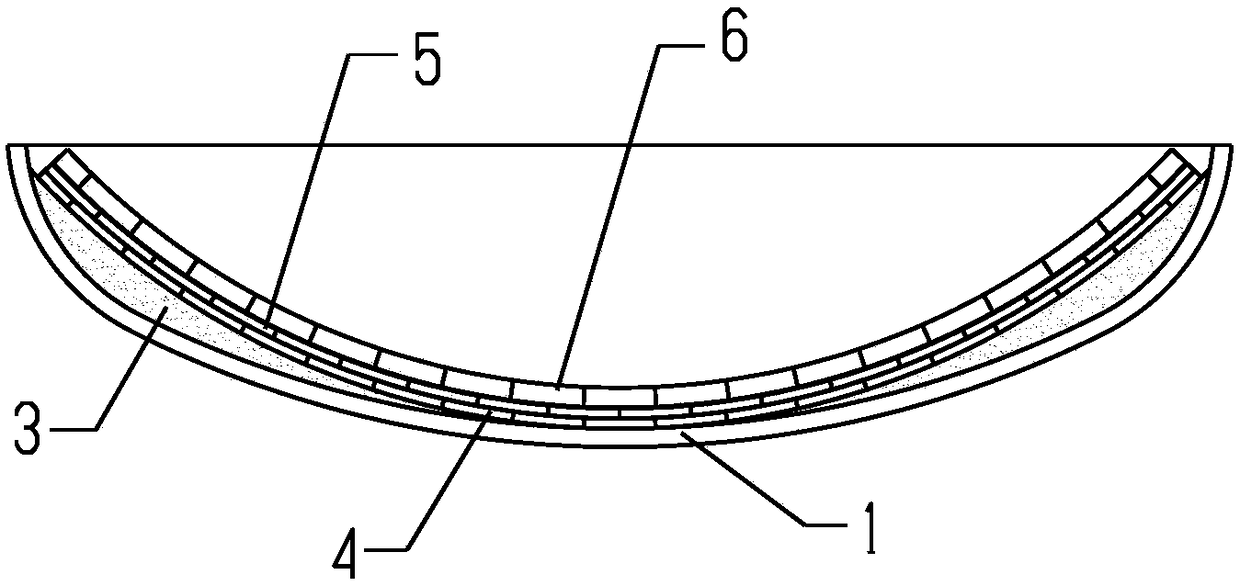

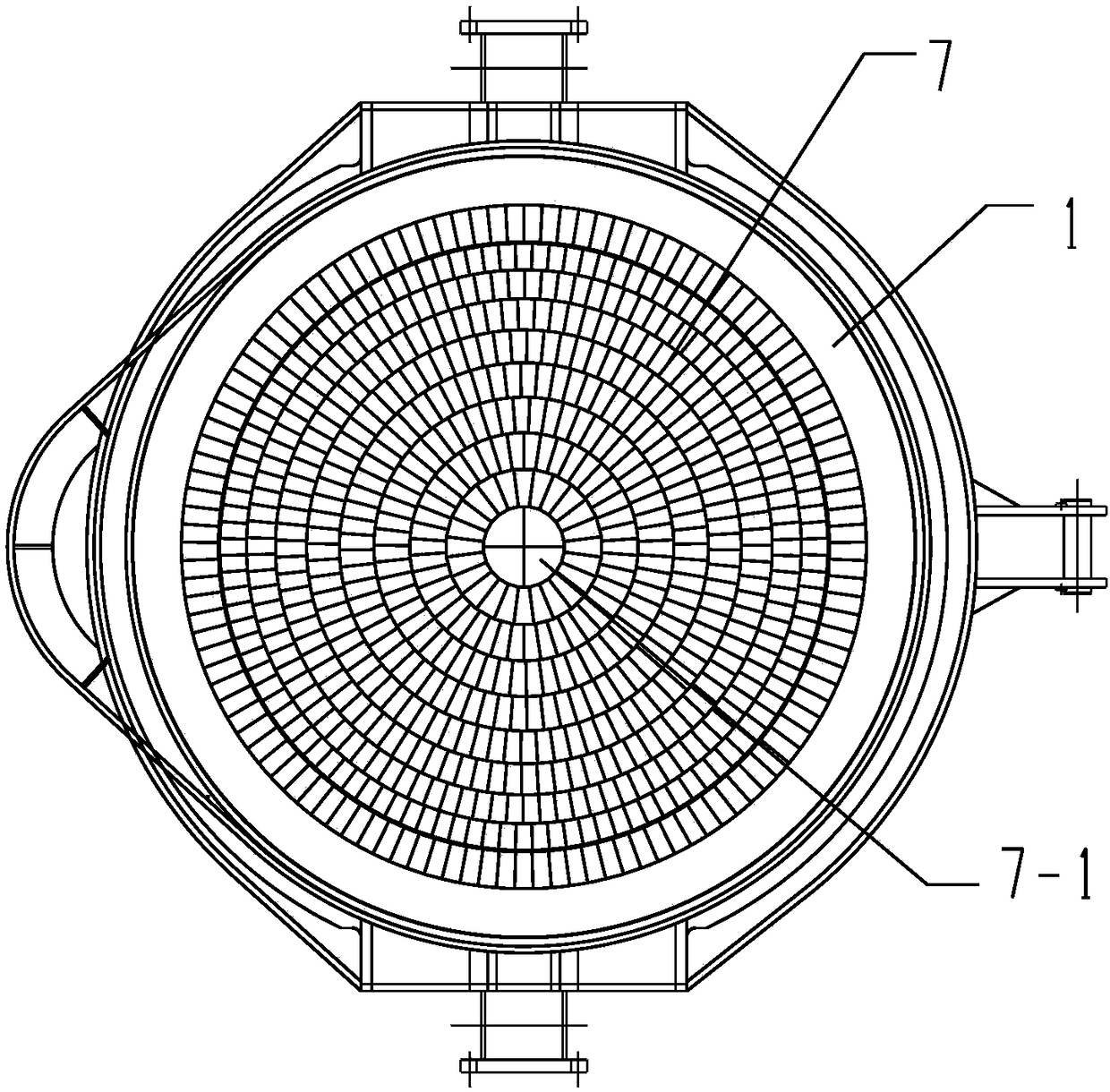

[0043] The present invention will be further described below in conjunction with drawings and embodiments. Such as figure 1 and figure 2 The ladle bottom lining structure of a kind of spherical bottom ladle shown, comprises permanent layer and ladle bottom working layer 7, as image 3 As shown, the bottom-covering working layer 7 is composed of a circular central part built by four central bricks 7-1 and a circular part formed by fan-shaped bricks by circular masonry. Each central brick 7-1 1 is a special-shaped brick with an arc-shaped cross section, and the four central bricks 7-1 have the same size and shape; the central brick and the fan-shaped brick of the bottom-covering working layer 7 are all made of aluminum silicon carbide refractory bricks. Such as figure 2 As shown, the permanent layer is sequentially composed of the first permanent layer 4, the second permanent layer 5 and the third permanent layer 6 from the outside to the inside, and a spherical tamping is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com