Vacuum diffusion welding connection method of molybdenum-base high-temperature alloy honeycomb structure

A technology of vacuum diffusion welding and high temperature alloy, applied in welding equipment, welding equipment, non-electric welding equipment and other directions, can solve the problems of scrap TZM alloy honeycomb structure parts, unqualified welding seam quality, etc. The effect of weld cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

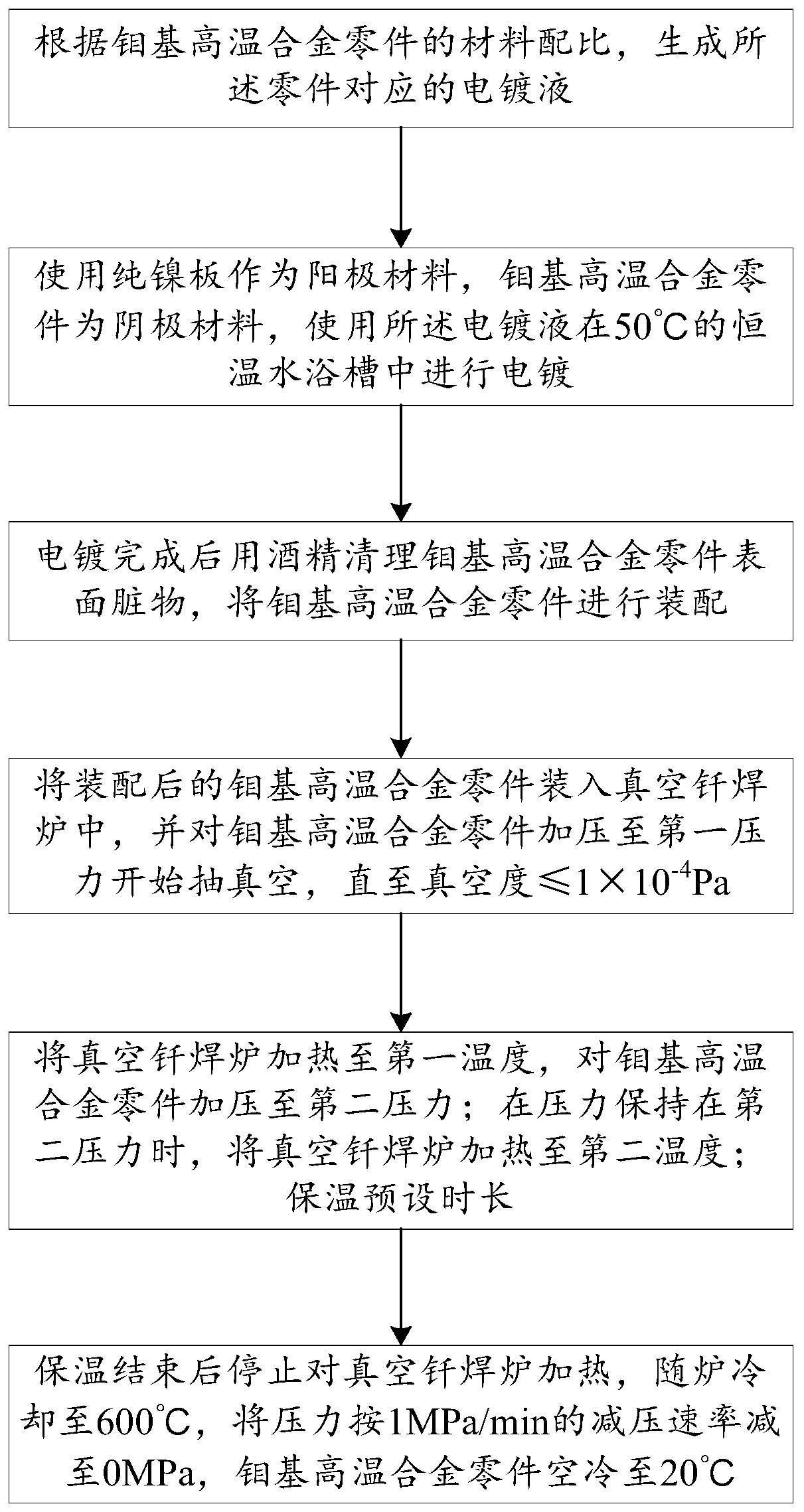

[0028] figure 1 It is a schematic flow chart of the vacuum diffusion welding connection method of the molybdenum-based superalloy honeycomb structure provided by the present invention. refer to figure 1 , the vacuum diffusion welding connection method of the molybdenum-based superalloy honeycomb structure provided by the present invention, comprising:

[0029] 1. Use 800 mesh sandpaper for mechanical polishing to remove surface oxides;

[0030] 2. Ultrasonic cleaning of parts to be welded to remove oil and other dirt on the surface to be welded;

[0031] 3. Use nickel sulfamate (350g / L) as the main salt, nickel chloride (30g / L) as the secondary salt, and add boric acid (40g / L) to adjust the pH of the plating solution to 4.8-5.0;

[0032] 4. Use pure nickel plate as the anode material, and the part to be welded is the cathode material. Use the electroplating solution prepared in the previous step to perform electroplating in a constant temperature water bath at 50 ° C. Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com