Method for recycling excess sludge of municipal sewage plant

A technology for excess sludge and municipal sewage, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc. Land resources, economical and reasonable effects of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present embodiment, the modified zeolite is prepared, and the steps are as follows:

[0037] Pulverize the natural zeolite, pass it through a 100-mesh sieve, soak the pulverized and sieved natural zeolite in a 1 mol / L sulfuric acid solution for 10 hours, wash it with deionized water to remove the sulfuric acid, dry it at 105 °C, and then place it in a 15 mol / L solution. The hexadecyltrimethylammonium bromide solution was stirred at a constant temperature of 25 ± 2 °C for 6 hours, washed with deionized water to remove the cetyltrimethylammonium bromide, dried at 105 °C, and then placed in 1mol / LCuSO 4 Soak in the solution for 10h, and dry at 105°C to obtain modified zeolite, numbered as 1# modified zeolite.

[0038] The natural zeolite was pulverized and passed through a 200-mesh sieve. The pulverized and sieved natural zeolite was soaked in a 0.5mol / L sulfuric acid solution for 12 hours, washed with deionized water to remove the sulfuric acid, dried at 105°C, a...

Embodiment 2

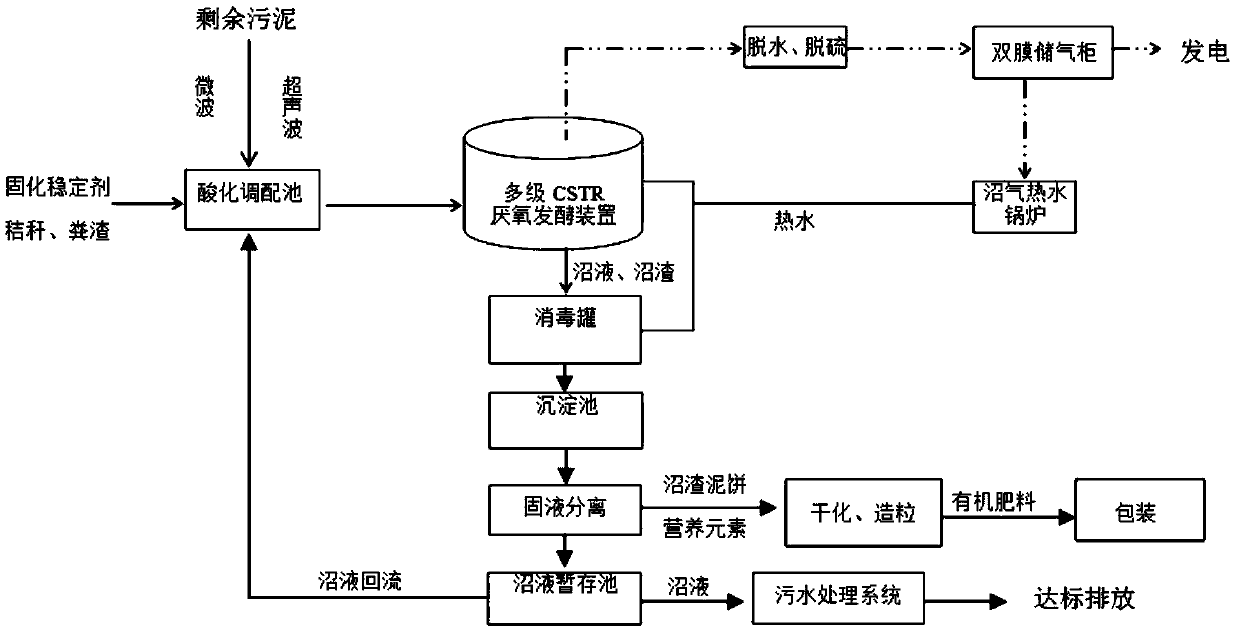

[0041] In this embodiment, taking the excess sludge produced by an urban domestic sewage treatment plant in a city in Guangdong Province as an example, the method for recycling excess sludge is described. The steps are as follows:

[0042] (1) The excess sludge is sent to the acidification mixing tank, the TS concentration of the sludge in the acidification mixing tank is adjusted to 10%, the pH value is 4.5, and the ultrasonic wave with the energy density of 0.05W / mL is used for 30s, and then the energy density is Microwave treatment at 1.0W / mL for 30s; then add the crushed straw that has passed through a 10-mesh sieve, and the amount of the crushed straw should be such that the dry matter mass of the crushed straw is 5% of the sludge mass in the acidification mixing tank; The 1# modified zeolite prepared in Example 1 was added to the acidification mixing tank, and the dosage of 1# modified zeolite was 0.5% of the mass of the sludge in the acidification mixing tank, and the he...

Embodiment 3

[0049] In this embodiment, taking the excess sludge produced by an urban domestic sewage treatment plant in a certain city in Guizhou Province as an example, the method for recycling excess sludge is described. The steps are as follows:

[0050] (1) The excess sludge is sent to the acidification mixing tank, the TS concentration of the sludge in the acidification mixing tank is adjusted to 10%, the pH value is 5, and the ultrasonic wave with the energy density of 0.5W / mL is used for 20s, and then the energy density is 3.0W / mL microwave treatment for 30s; then add manure residue, the amount of manure residue added should be 25% of the sludge mass in the acidification blending tank as the dry matter mass of the manure residue; then add the prepared by Example 1 to the acidification blending tank. 2# modified zeolite, the dosage of 2# modified zeolite is 1.5% of the sludge mass in the acidification mixing tank, and the heavy metal ions in the sludge are subjected to adsorption and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com